Preparation method of anti-melting nylon sheet based on surface structured flame retardant technology

A surface structuring and anti-droplet technology, which is applied in the field of flame retardant materials, can solve the problems that it is difficult to form a good and stable cross-linking system, it is difficult to achieve the effect of flame retardant gain, and affect the mechanical properties of the substrate, reaching the level of vertical combustion Improvement, improvement of droplet phenomenon, excellent flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

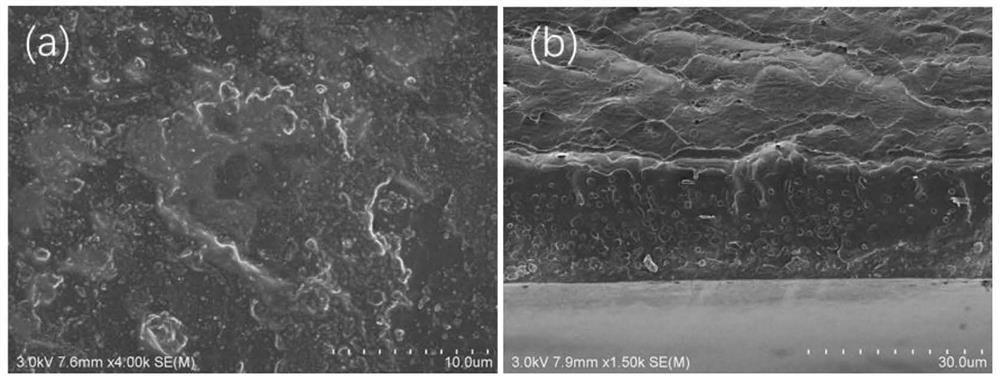

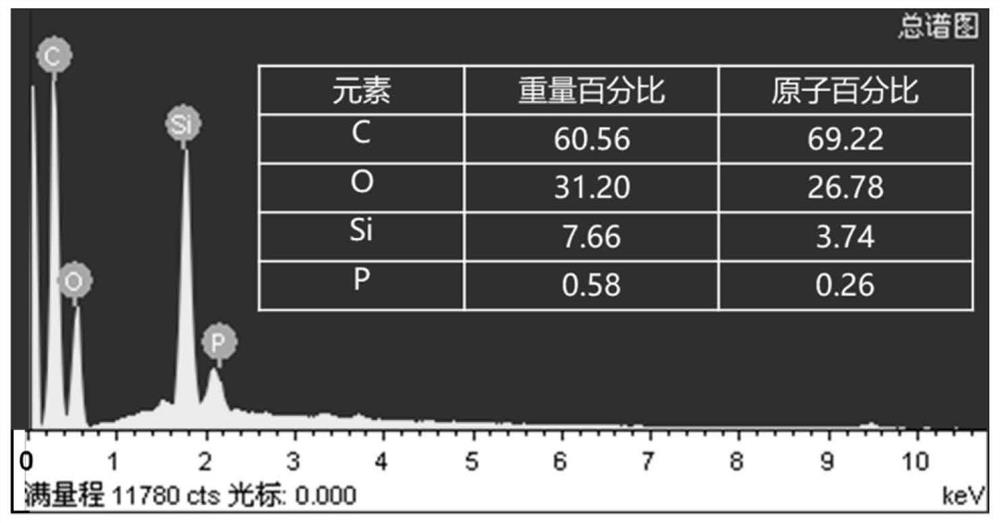

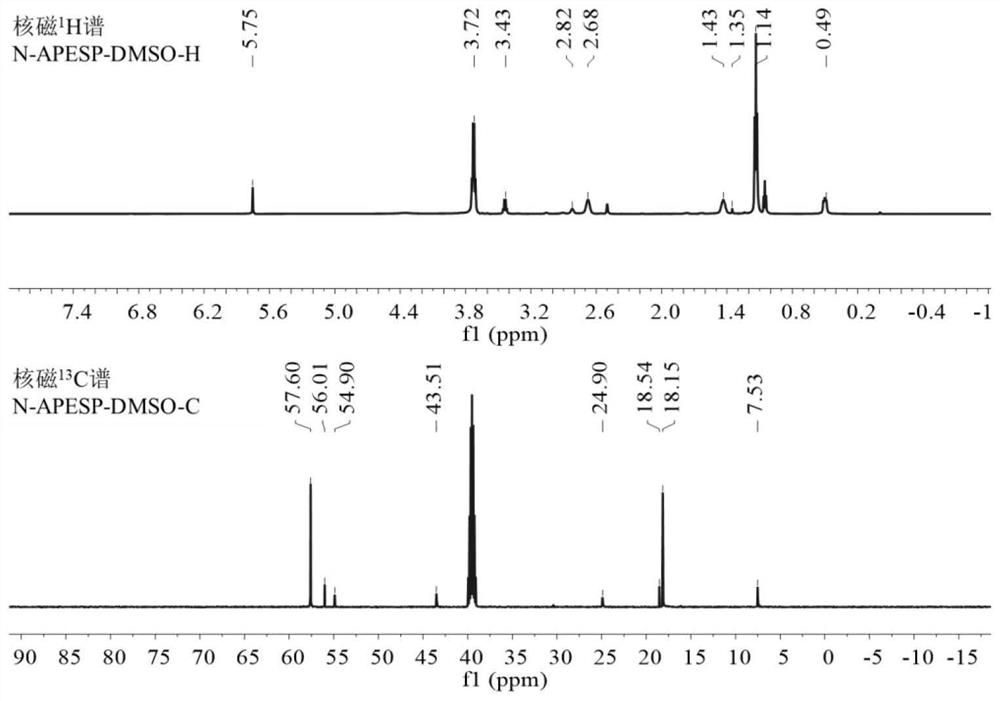

Embodiment 1

[0043] Dissolve 3.47g of hexachlorocyclotriphosphazene (HCCP) in 50ml of tetrahydrofuran, place in a three-necked flask and heat to 67°C, introduce nitrogen, and stir with a magnet in an oil bath; mix 0.88g of propylenediamine, 14.61g of KH550 and 7.28g of triethylamine were dissolved in 50ml of tetrahydrofuran, added to the constant pressure funnel, slowly added to the three-necked flask filled with HCCP solution at a constant speed, and after 24 hours of continuous heating, the reacted mixture was passed through the funnel Filtration to obtain a filtrate; the solution system obtained after filtration is subjected to rotary evaporation to remove most of the solvent and raw materials such as excess triethylamine, and further removes the residual solvent through a mechanical pump; the viscous yellow-green liquid after vacuum drying Dissolve in 200 ml of ethyl acetate, add saturated brine to wash and separate with water, wash with water 3 times, each time using about 150 ml of sa...

Embodiment 2

[0050] Dissolve 3.47g of hexachlorocyclotriphosphazene (HCCP) in 50ml of tetrahydrofuran, place in a three-necked flask and heat to 67°C, introduce nitrogen, and stir with a magnet in an oil bath; mix 0.88g of propylenediamine, 14.61g of KH550 and 7.28g of triethylamine were dissolved in 50ml of tetrahydrofuran, added to the constant pressure funnel, slowly added to the three-necked flask filled with HCCP solution at a constant speed, and after 24 hours of continuous heating, the reacted mixture was passed through the funnel Filtration to obtain a filtrate; the solution system obtained after filtration is subjected to rotary evaporation to remove most of the solvent and excess triethylamine and other raw materials, and further removes the residual solvent through a mechanical pump; the viscous yellow-green liquid after vacuum drying Dissolve in 200 ml of ethyl acetate, add saturated brine for washing and separation, repeat washing 3 times with about 150 ml of saturated brine ea...

Embodiment 3

[0054] Dissolve 3.47g of hexachlorocyclotriphosphazene (HCCP) in 50ml of tetrahydrofuran, place in a three-necked flask and heat to 67°C, introduce nitrogen, and stir with a magnet in an oil bath; mix 0.88g of propylenediamine, 14.61g of KH550 and 7.28g of triethylamine were dissolved in 50ml of tetrahydrofuran, added to the constant pressure funnel, slowly added to the three-necked flask filled with HCCP solution at a constant speed, and after 24 hours of continuous heating, the reacted mixture was passed through the funnel Filtration to obtain a filtrate; the solution system obtained after filtration is subjected to rotary evaporation to remove most of the solvent and excess triethylamine and other raw materials, and further removes the residual solvent through a mechanical pump; the viscous yellow-green liquid after vacuum drying Dissolve in 200 ml of ethyl acetate, add saturated brine for washing and separation, repeat washing 3 times with about 150 ml of saturated brine ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com