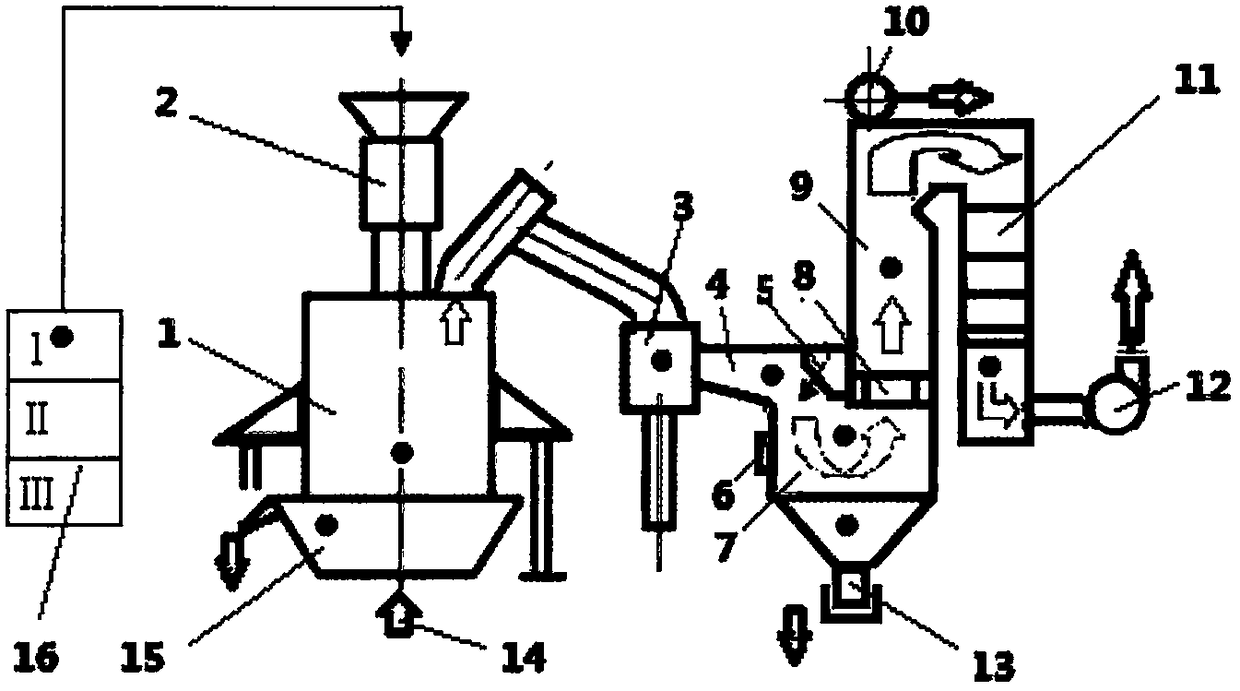

Carbon-molecule gasification combustion boiler engineering operation system

An operation system and gasifier technology, which is applied in the field of large-scale carbon-molecular gasification combustion boiler engineering operation system, and can solve the problems of high gas production cost, pollution and serious problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] According to the accompanying drawings, the engineering operation of the carbon-molecular gasification combustion boiler system is further explained: the entering coal 16 is first tested according to the national standard to determine the elemental composition and provide a basis for subsequent combustion; Granularity coal and pulverized coal are produced, step II pulverized coal is reinforced with sulfur agent to make pellets (the control point here is based on the sulfur content, according to the composition of Ca / S close to 1 ratio), step III coal pellets are dried, and then sent to the coal bunker together, Then use the coal stoker 2 to feed into the carbon-molecular gasification furnace 1 to realize sulfur fixation and gas production under anoxic conditions; the gasification agent 14 is added from the bottom of the furnace, and the raw coal and gasification agent move in reverse in the furnace; the sulfur-containing slag It is discharged from the ash tray 15 and use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com