Meat product rich in dietary fibers and preparation method of meat product

A technology for dietary fiber and meat products, which is applied in the field of food processing, can solve the problems that the meat filling is difficult to disperse evenly, the meat filling is difficult to mix evenly, and the product quality is affected, so as to reduce cooking loss, improve product quality, and reduce moisture absorption strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

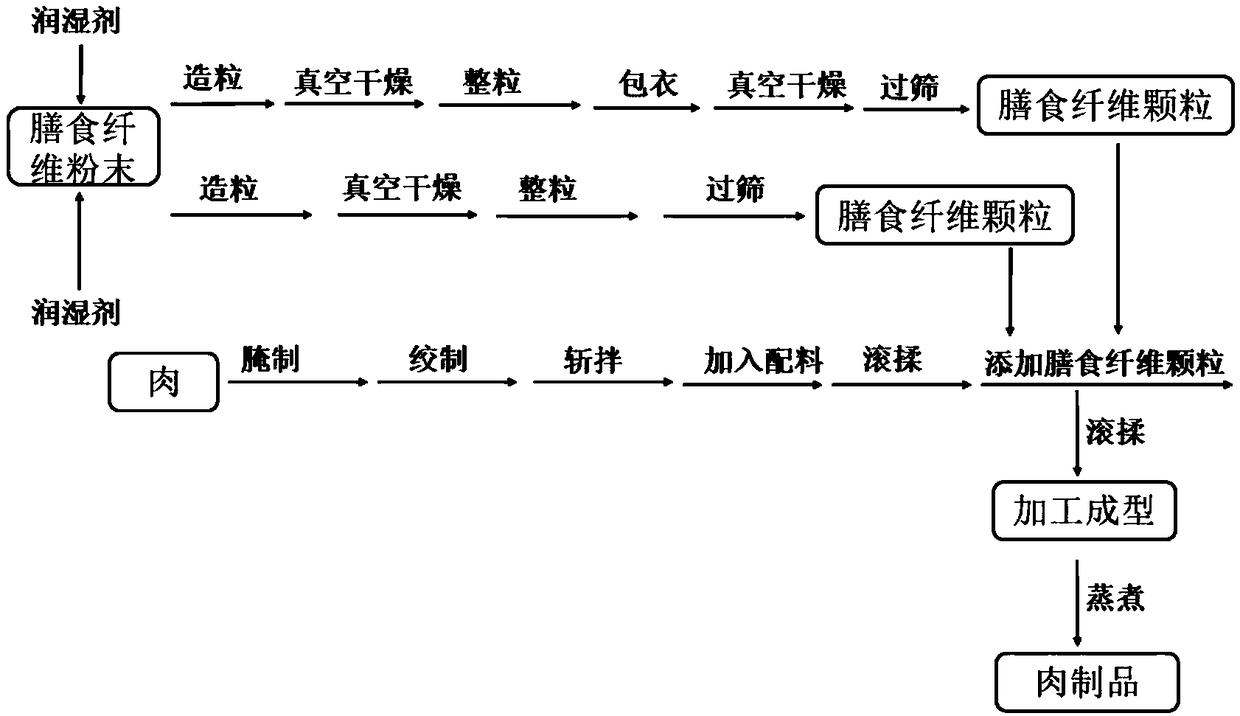

[0036] A kind of preparation method of the above-mentioned meat product rich in dietary fiber of the present invention, comprises the following steps:

[0037] Step 1: Cut the meat into pieces, add sliced ginger, green onions, cooking wine, and soy sauce and marinate for 2-3 hours;

[0038] Step 2: Finely mince the marinated meat, then chop it into minced meat, add spices to the minced meat, put it in a tumbler and stir evenly, then add dietary fiber particles in batches, mix evenly again, and set aside;

[0039] Step 3: Process with meat product processing equipment to make meat products rich in dietary fiber.

Embodiment 1

[0042] First take a certain amount of fructo-oligosaccharide powder (purity ≥ 90%) and place it in the granulator, spray an appropriate amount of 80% ethanol solution into the cylinder of the high-speed mixing granulator, and make soft powder by wet method, and then use the side-mounted The high-speed crushing paddle is used for stirring, cutting and granulating, so that the prepared material can be kneaded into a ball by hand and dispersed by light pressure. The preliminarily prepared fructo-oligosaccharide particles were vacuum-dried at 55° C. for 6 hours. According to 5% configuration coating solution of dry fructo-oligosaccharide granule quality, hydroxypropyl methylcellulose is dissolved in the ethanol solution of 50%, under 40 ℃ of conditions, carry out coating process in coating pan, again in Vacuum-dry at 55°C for 12 hours, and use an analytical sieve to separate particles according to particle size to obtain a sample of fructo-oligosaccharide particles with a particle...

Embodiment 2

[0046] First, take a certain amount of inulin dietary fiber powder (purity ≥ 90%) and place it in the granulator, spray 95% ethanol solution into the cylinder of the high-speed mixing granulator, and make soft powder by wet method, and then use the side-mounted The high-speed crushing paddle is used to stir, cut and granulate, so that the prepared material is moderate, and it can be kneaded into a ball by hand, and then dispersed by light pressure. The preliminarily prepared fructo-oligosaccharide particles were vacuum-dried at 55° C. for 10 h. An analysis sieve is used to separate the particles according to the particle size to obtain a fructooligosaccharide particle sample with a particle size of 60-100 mesh.

[0047] In this example, a chicken ham sausage rich in dietary fiber is composed of the following components in parts by mass: 1000 kg of chicken, 120 kg of inulin granules, 55 kg of cooking wine, 45 kg of ginger, 50 kg of green onion, 200 kg of spices, and 200 kg of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com