Technology for preparing Fe3O4/mesoporous carbon composite material by one-step synthesis process, and method for catalytic oxidation degradation of sulfamethazine by using composite material

A sulfamethazine, composite material technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as easy agglomeration, and achieve unique The effect of secondary pollution, simple process flow and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This example examines Fe 3 O 4 / Mesoporous carbon composite material in different dosage of sulfamethazine adsorption efficiency.

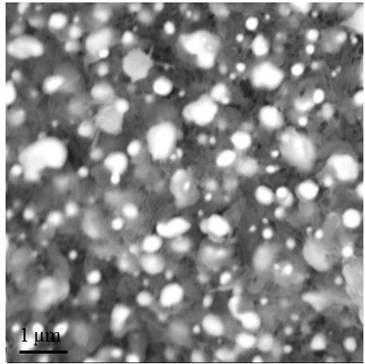

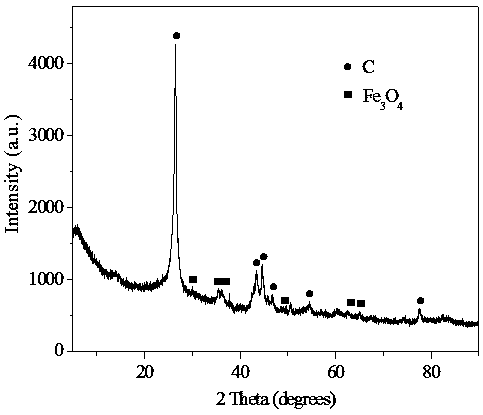

[0032] (1) The FeCl with a molar ratio of 2:1 3 ·6H 2 O and FeCl 2 ·4H 2 O (of which FeCl 3 ·6H 2 O take 21.64g, FeCl 2 ·4H 2 O take 7.96g) Dissolve a constant volume 100mL volumetric flask with oxygen-free water. 0.9mol·L at room temperature -1 Add the ammonia droplets to the above-mentioned iron salt mixture, stir vigorously while adding, and pass nitrogen protection. Add ammonia water dropwise to around pH 9.0, the amount of ammonia water is about 700mL, keep nitrogen gas and stir for 30min, then settle for 30min, pour off the supernatant, wash with oxygen-free water three times to make the pH nearly neutral, and then use a centrifuge (3000rpm ) Centrifuge for 10 min, pour out the supernatant, put the product in a constant temperature drying oven and dry at 95℃ to obtain Fe 3 O 4 .

[0033] (2) Combine PVA and Fe prepared in step (1) 3 O 4 A...

Embodiment 2

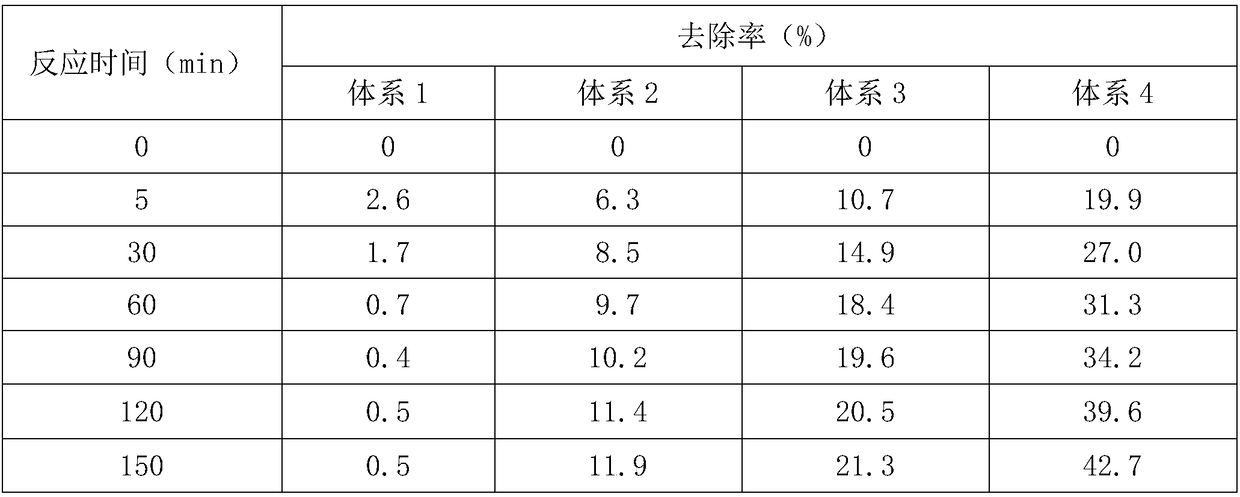

[0040] This example compares different Fe 3 O 4 The effect of activated sodium persulfate on the removal rate of sulfamethazine under the condition of the dosage of mesoporous carbon composite material.

[0041] Fe involved in this embodiment 3 O 4 The preparation method of the mesoporous carbon composite material is the same as in Example 1.

[0042] Utilize prepared Fe 3 O 4 / Mesoporous carbon composite material is the catalyst, and its dosage is 0.0696, 0.1392, 0.2088, 0.2784, and 0.3480g, which are denoted as systems 1, 2, 3, 4 and 5 respectively; sulfamethazine is the target pollutant. The initial concentration of the aqueous solution is 50mg / L and the volume is 100mL; the mass of sodium persulfate is 0.0476g, the reaction temperature is 30°C, the pH is not adjusted, and the conical flask is used as the reactor. Place them in a constant temperature oscillator and oscillate for a certain period of time, take samples at 15, 30, 45, 60, 75, and 90 minutes, and measure the concent...

Embodiment 3

[0048] This example compares the effects of different qualities of the oxidant sodium persulfate on the degradation rate of sulfamethazine.

[0049] Fe involved in this embodiment 3 O 4 The preparation method of the mesoporous carbon composite material is the same as in Example 1.

[0050] Utilize prepared Fe 3 O 4 / Mesoporous carbon composite material is the catalyst, its dosage is 0.1392g, sulfamethazine is the target pollutant, the initial concentration of its aqueous solution is 50mg / L, the volume is 100mL; the mass of sodium persulfate is 0, 0.0119, 0.0238, 0.0476, 0.0714, 0.1190g, respectively denoted as systems 1, 2, 3, 4, 5, and 6; the reaction temperature is 30°C, the pH is not adjusted, and the conical flask is used as the reactor. Place them in a constant temperature oscillator and oscillate for a certain period of time, take samples at 15, 30, 45, 60, 75, and 90 minutes, and measure the concentration of the supernatant after the reaction.

[0051] Table 3 shows the effic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com