Method for removing iodo-X-ray contrast medium in water

An X-ray and water-removing technology, which is applied in the field of removing iodine X-ray contrast agents in water, can solve problems such as difficult removal and human hazards, and achieve the effects of outstanding safety, good stability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Iodine X-ray contrast agents in water mainly include iohexol, iopamidol, iopromide, iomeprol and ionic diatrizoate. Free radicals (·OH) can degrade iopamidol, but other X-ray contrast agents are difficult to degrade through OH, and the bond breaking energy required by iohexol for its degradation is The highest, especially the bond breaking between the carbon on the benzene ring and the iodine element needs to span energy, which requires extremely high oxidation ability of free radicals, and it is difficult for other conventional oxidative degradation agents to degrade it, so iodine is selected in this embodiment. Take hexanol as an example.

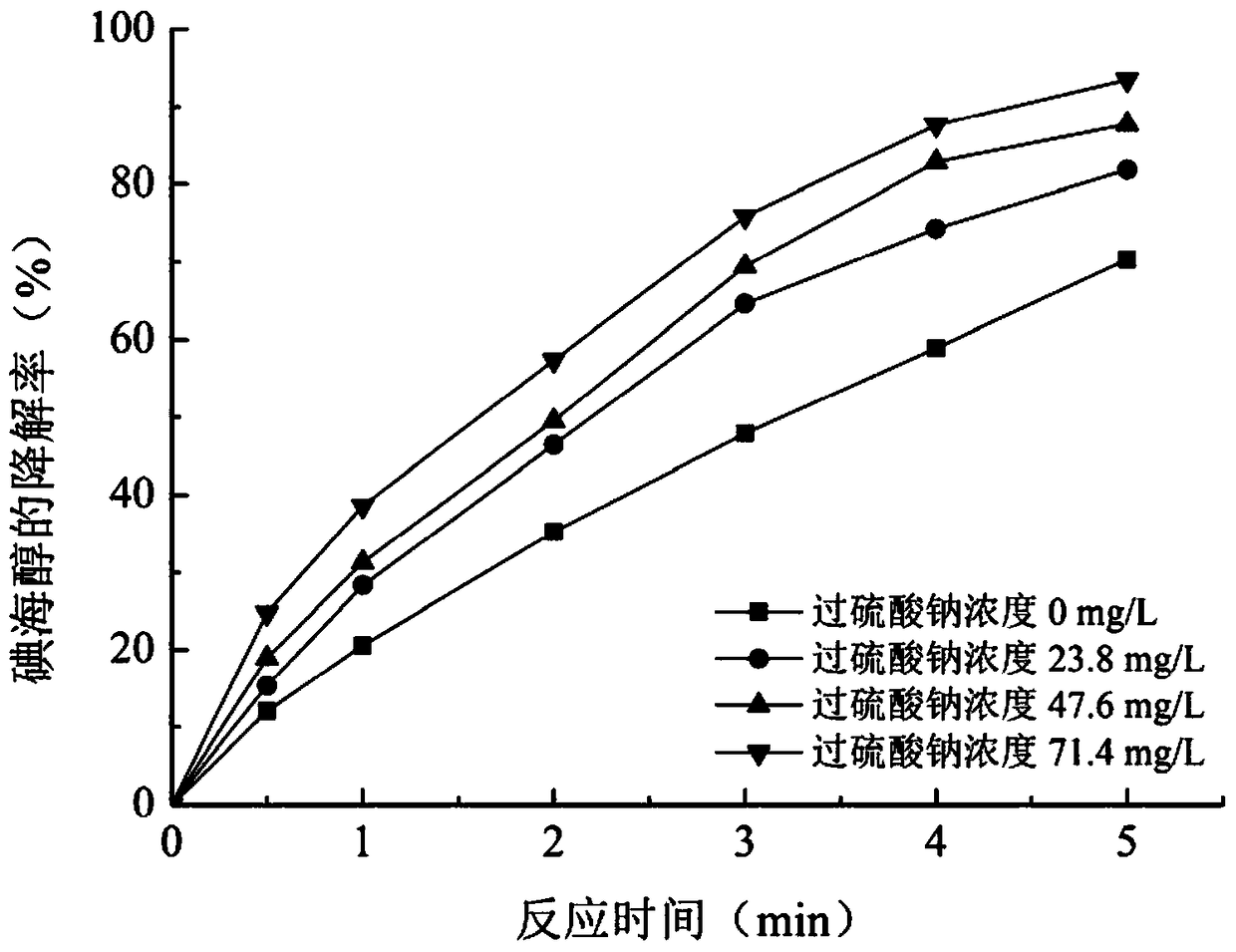

[0030] During the degradation process, adjust the raw water containing 10 μM iohexol to pH = 7, control the temperature at 25°C, add sodium persulfate to the reaction solution and stir at a low speed to make it evenly mixed. After 2 minutes, the reaction solution is subjected to ultraviolet light. irradiated. Calculated according...

Embodiment 2

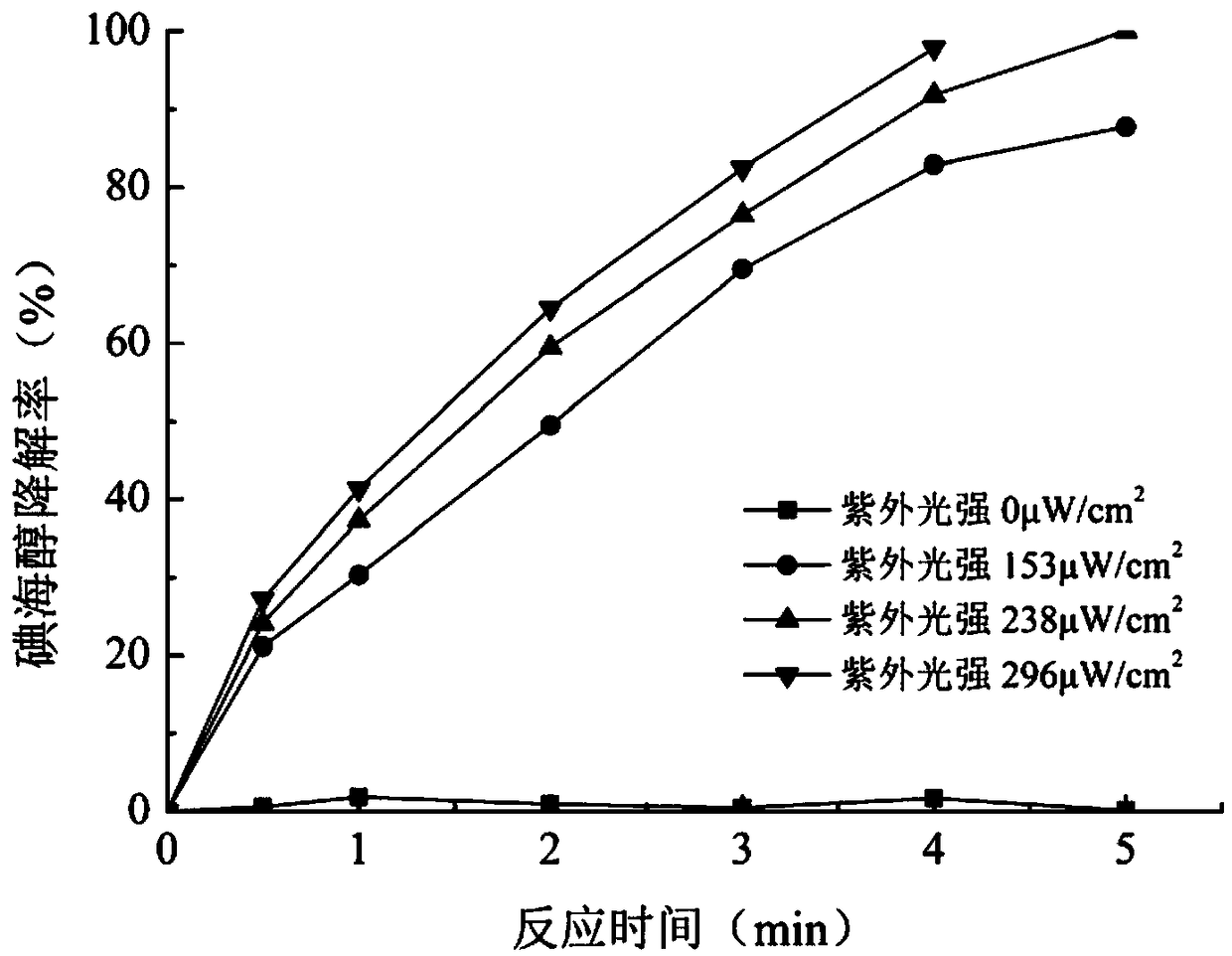

[0033] Taking iohexol as an example, adjust the raw water containing 10 μM iohexol to pH = 7, control the temperature at 25°C, add sodium persulfate to the reaction solution and stir at a low speed to make it evenly mixed, the dosage of sodium persulfate It was 47.6 mg / L, and after 2 minutes, the reaction solution was irradiated with ultraviolet light. Calculated according to the concentration of substances in water, the intensity of ultraviolet light is 0μW / cm 2 、153μW / cm 2 、238μW / cm 2 , 296μW / cm 2 , the degradation rate of iohexol varies with the reaction time as figure 2 shown.

[0034] Sodium persulfate could not oxidize iohexol alone without ultraviolet light irradiation, and the degradation rate of iohexol was significantly increased by ultraviolet light irradiation, and it was positively correlated with the intensity of ultraviolet light.

Embodiment 3

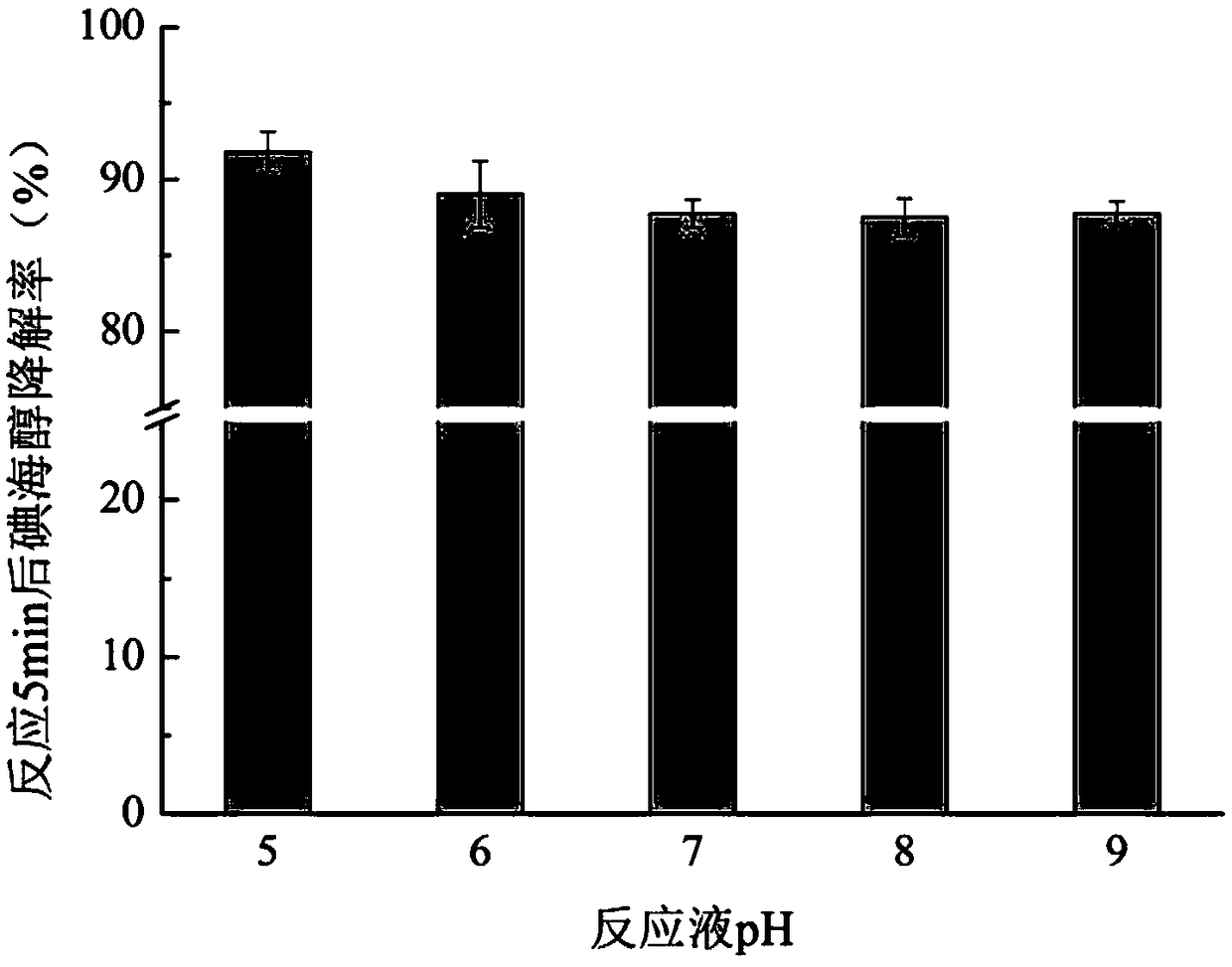

[0036] Take iohexol as an example, control the temperature at 25°C, add sodium persulfate to the raw water containing 10 μM iohexol and stir at a low speed to mix well, the dosage of sodium persulfate is 47.6mg / L, after 2min The reaction solution was irradiated with ultraviolet light. Calculated according to the concentration of substances in water, when the pH is 5, 6, 7, 8, and 9 respectively, the relationship between the degradation rate of iohexol and the pH of the reaction solution after 5 minutes of reaction is as follows image 3 shown.

[0037]The degradation rate of iohexol is less affected by pH changes within a certain pH range (pH=5-9), and the degradation rate under neutral and weakly alkaline conditions is basically the same, while the degradation effect is slightly improved under weakly acidic conditions. And the degradation rate exceeds 90%. Generally speaking, the degradation rate does not decrease significantly with the change of pH, therefore, the method h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| UV radiation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com