Polypropylene composition and polypropylene material and application thereof

A technology of polypropylene composition and polypropylene material, applied in the field of polypropylene material, application of polypropylene material, polypropylene composition, can solve problems such as defects in the performance of parts, reduced toughness, etc., to improve processing performance and improve molding Speed, the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] During the preparation of the compatibilizer, the temperature of the melt blending reaction can be the conventional blending temperature used in POE processing, as long as the matrix resin can be completely melted without decomposing it. Preferably, the temperature of the melt blending reaction is 210-230°C.

[0024] In the present invention, the polypropylene may be a random copolymer polypropylene whose comonomer is ethylene. Preferably, the melt flow index of the polypropylene at 230°C under a load of 2.16kg is 20-40g / 10min. In addition, the polypropylene can be obtained commercially, for example, the grades are 7726 and 9020.

[0025] In the present invention, barium sulfate is used as the filler, and the barium sulfate has good thermal stability, dimensional stability and aging resistance, and the shrinkage rate of the product is low, and the coefficient of linear expansion is low. Barium sulfate can be technical grade products. The particle size of the barium s...

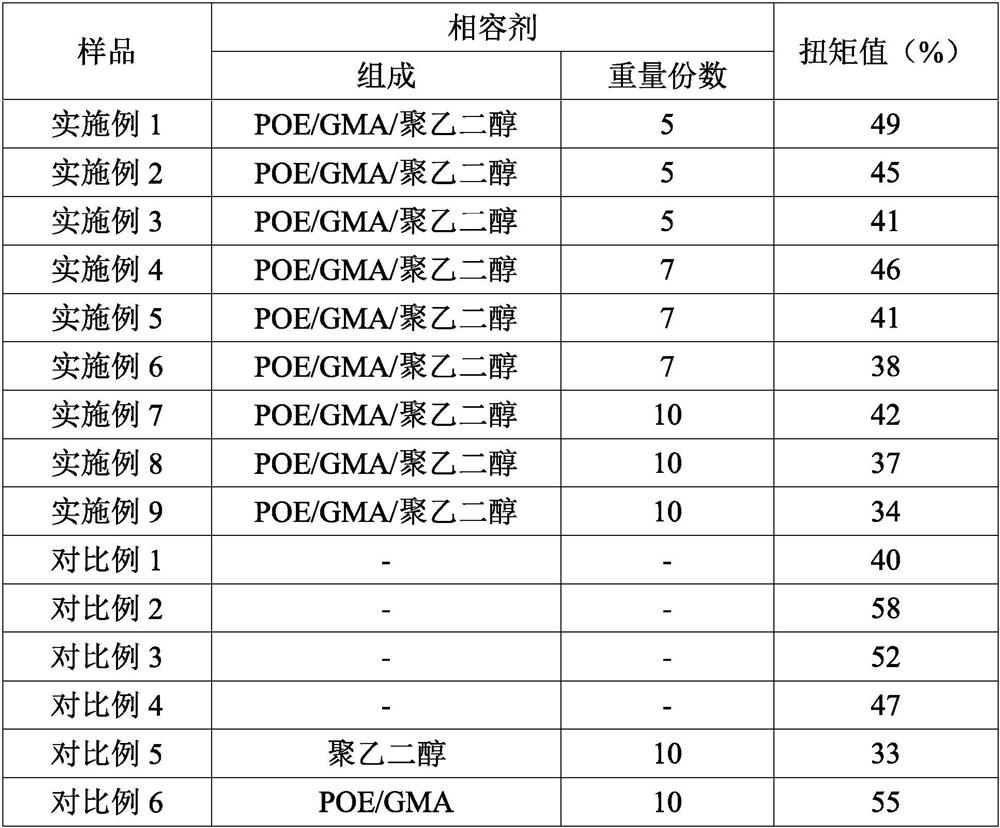

Embodiment 1

[0054] This example is used to illustrate the polypropylene composition and polypropylene material of the present invention.

[0055] Based on the total weight of the polypropylene composition, the composition of the polypropylene composition is as follows: 70 parts of polypropylene, 30 parts of barium sulfate, 5 parts of compatibilizer, 0.32 parts of antioxidant (weight ratio is 1: 1 antioxidant agent 1010 and antioxidant 168).

[0056] Based on the total weight of the compatibilizer, the compatibilizer is prepared by melt-blending reaction of 100 parts of POE, 3 parts of GMA and 15 parts of polyethylene glycol. Specifically, add POE, GMA and polyethylene glycol into a high-speed mixer, stir at room temperature for 3 minutes to mix the materials evenly, and inject the mixed materials into the reactive twin-screw extruder through a liquid metering pump, at 210-230 The compatibilizer was obtained by melt blending at a temperature of 300 rpm with a screw speed of 300 rpm, extru...

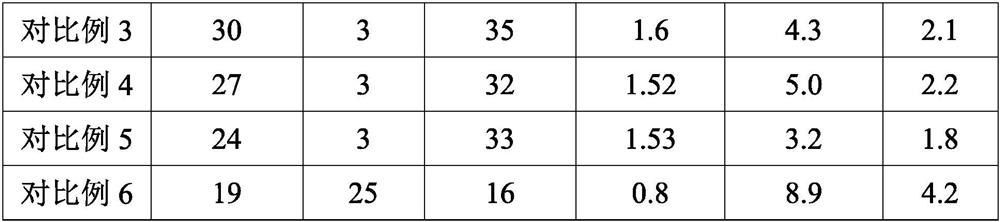

Embodiment 2~3

[0059] The method for preparing polypropylene material with reference to embodiment 1, difference is that the polypropylene in the polypropylene composition of embodiment 2 is 80 parts, barium sulfate is 20 parts, the polypropylene in the polypropylene composition of embodiment 3 90 parts for barium sulfate and 10 parts for barium sulfate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com