A temperature field regulation mechanism that facilitates the control of directional solidification and flat liquid-solid interface

A liquid-solid interface, directional solidification technology, applied in the field of photovoltaics, can solve the problems of solidified melt vibration, central supercooling, adverse effects of crystal growth, etc., to improve heat transfer efficiency, ensure overall quality, and increase the effect of disturbance effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

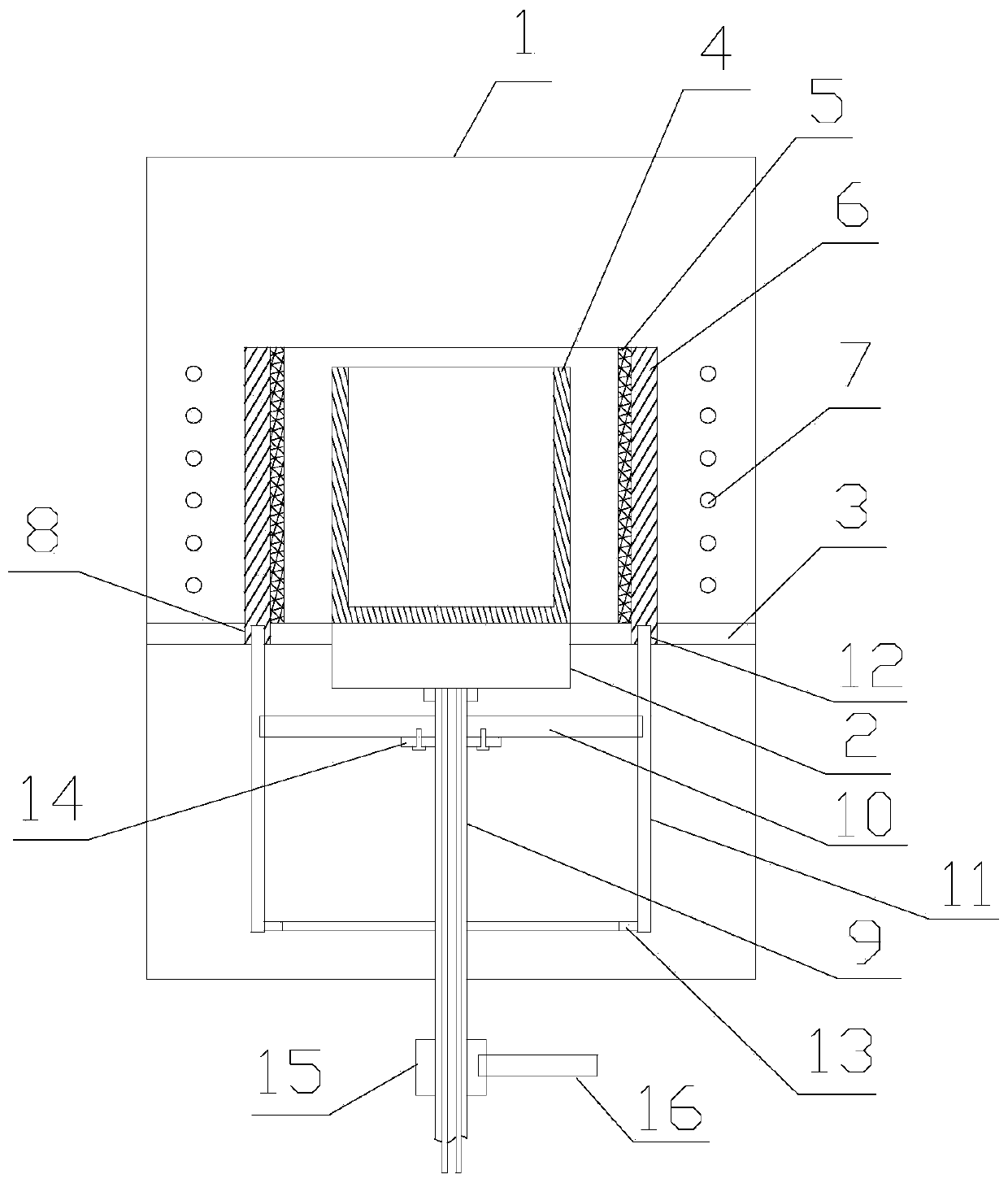

[0041] This embodiment provides a temperature field control mechanism that is beneficial to control the directional solidification and flat liquid-solid interface, including a furnace body 1, a cooling plate 2 with a coaxial center line is provided in the furnace body 1, and a There is a heat insulation ring plate 3, the radial outer edge of the heat insulation ring plate 3 is in contact with the inner wall of the furnace body 1, and the radial inner edge is in contact with the outer wall of the cooling plate 2; the crucible 4 is placed on the upper plate of the cooling plate 2, and the crucible 4. The outer jacket is provided with a thermal insulation tube 6, the inner wall of the thermal insulation tube 6 is fixed with a graphite heating element 5, and the outer ring of the thermal insulation tube 6 is provided with an electromagnetic induction coil 7;

[0042] There is also a ring groove 8 on the heat insulation ring plate 3, the axial bottom end of the insulation tube 6 fit...

Embodiment 2

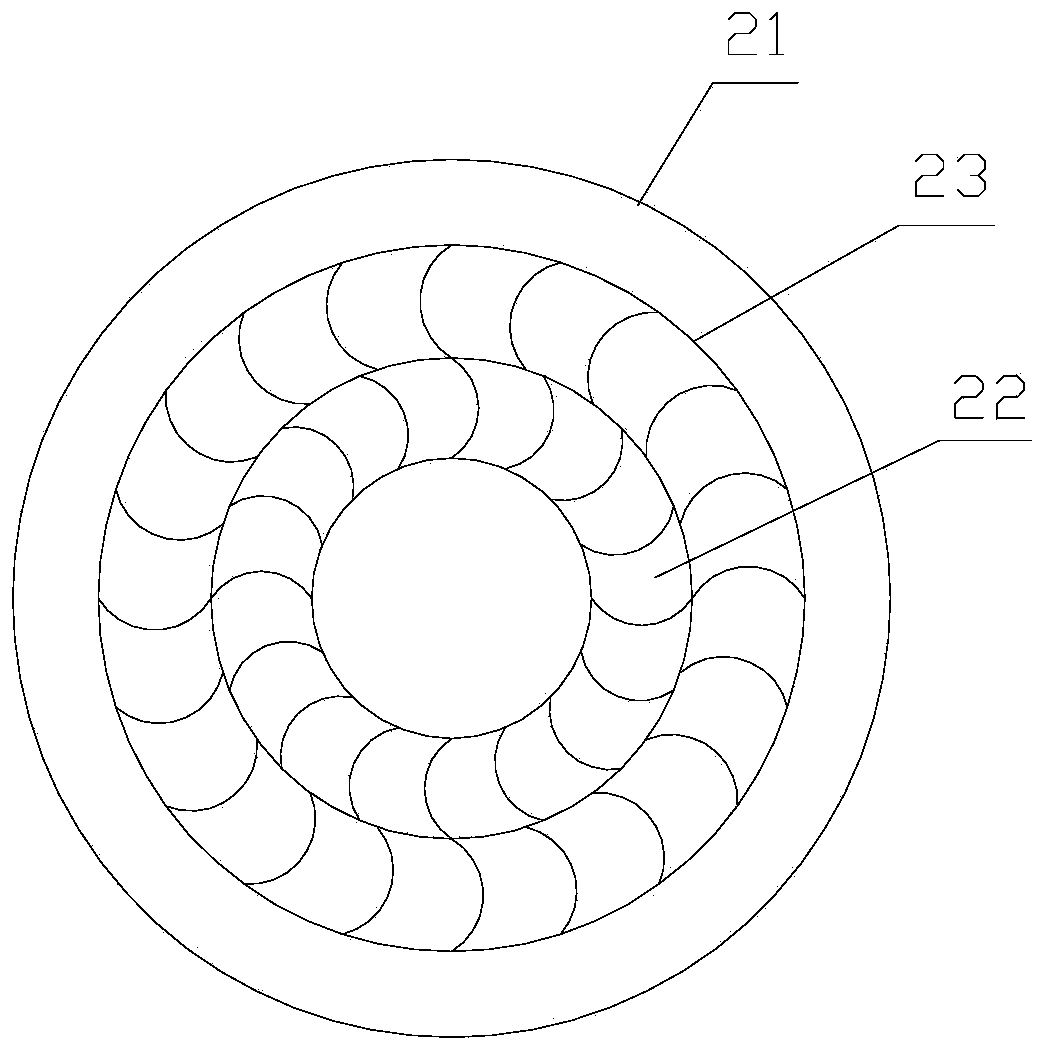

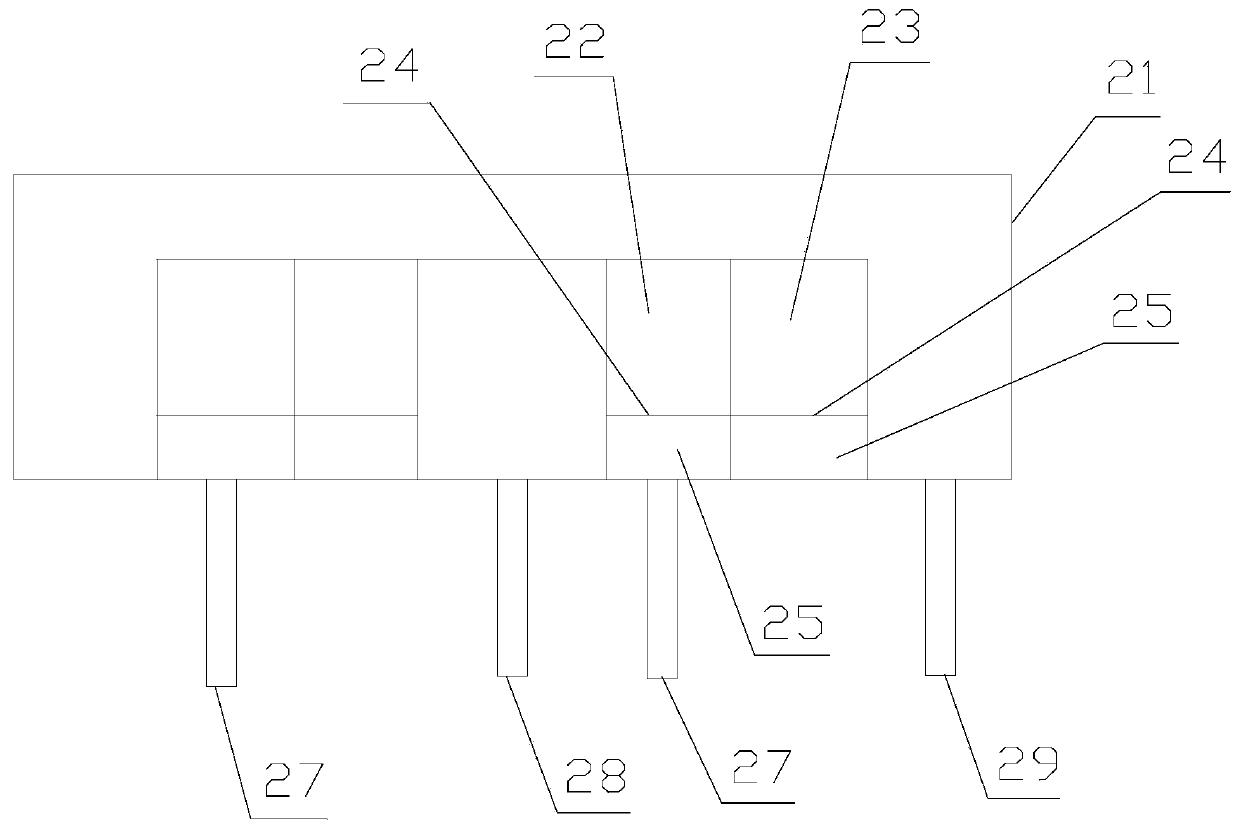

[0045] Further improvement on the basis of Embodiment 1, the fins 26 on the first annular gas distribution chamber 22 and the second annular gas distribution chamber 23 are distributed at equal intervals along the circumference, and the gas output end of each fin 26 The direction of the board surface is arranged obliquely, and the inclination angle relative to the bottom surface of the housing 21 is 60-80°. The fins 26 in the first annular gas distribution chamber 22 are all inclined clockwise, and the fins 26 in the second annular gas distribution chamber 23 are all inclined counterclockwise. The pressure difference between the gas pressure passing into the first annular gas distribution chamber 22 and the gas passing into the second annular gas distribution chamber 23 is 0.05-0.15 MPa.

Embodiment 3

[0047] Further improvement on the basis of Example 2, the lifting mechanism includes a rotating sleeve 9, a driven disc 10 and a driving mechanism; the furnace body 1 below the heat insulating ring plate 3 extends into the rotating sleeve 9, and the rotating One axial end of the sleeve 9 is driven to rotate by the driving mechanism, and the other axial end is rotationally connected with the lower plate surface of the cooling plate 2; An adjustment cylinder 11 is threadedly connected to the edge, and the axial upper end of the adjustment cylinder 11 is connected to the heat preservation cylinder 6 by being embedded in the limit card slot 12; , drive the adjusting cylinder 11 to move up and down through screw transmission, thereby pushing the heat preservation cylinder 6 and the graphite heating element 5 to move up or down. The air intake pipe 27 , the first exhaust pipe 28 and the second exhaust pipe 29 all pass through the rotating sleeve 9 and protrude to the external enviro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com