Preparation method and application of polyvinyl alcohol nonwoven fabric finishing agent

A polyvinyl alcohol, non-woven technology, applied in fiber processing, textiles and papermaking, improved hand-feeling fibers, etc., can solve certain limitations in the application field, low efficiency of polyvinyl alcohol non-woven fabrics, and poor heat sealing. performance and other issues, to achieve the effect of improving mechanical properties, strengthening overall performance, and improving elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The padding finishing of polyvinyl alcohol nonwoven fabric specifically comprises the following steps:

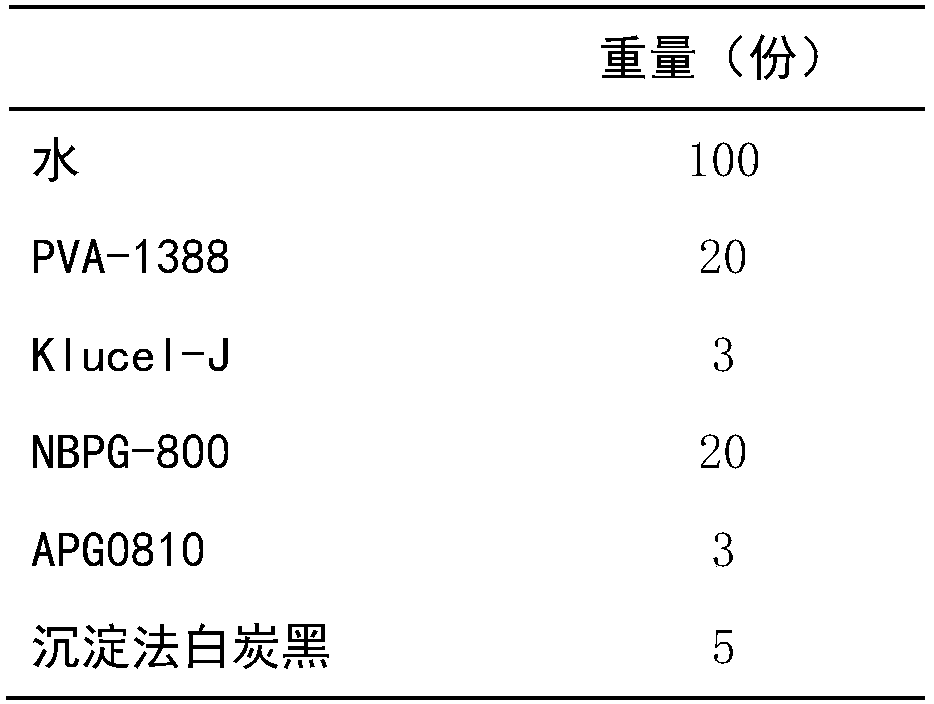

[0041] (1) The impregnating finishing agent for finishing includes the following components in parts by weight (see Table 1):

[0042] Table 1

[0043]

[0044]

[0045] After measuring the materials in the above components, add them to a dissolution vessel with a heating jacket, raise the temperature to 95°C under stirring (50 rpm), mix and dissolve for 4 hours, and keep warm at 90°C for 30 minutes, then cool down to room temperature Discharge is standby, is the finishing agent of a kind of polyvinyl alcohol non-woven fabric of the present invention;

[0046] (2) Specification of polyvinyl alcohol non-woven fabric for finishing: 28g / m 2 ;

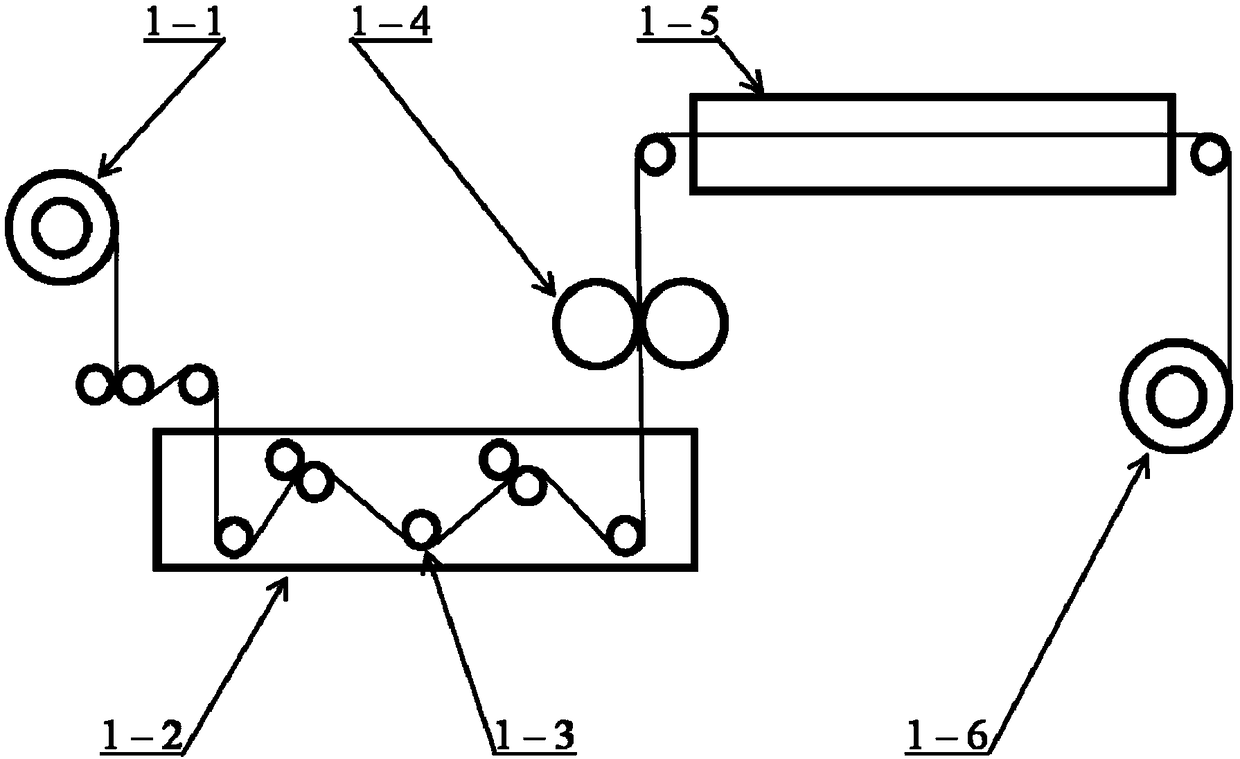

[0047] (3) padding finishing process (see figure 1 ): release the polyvinyl alcohol non-woven fabric by the unwinding roller 1-1, enter the impregnation tank 1-2 filled with the finishing agent of embodiment 1 through t...

Embodiment 2

[0053] The padding finishing of polyvinyl alcohol nonwoven fabric specifically comprises the following steps:

[0054] (1) The impregnating finishing agent for finishing includes the following components in parts by weight (see Table 3):

[0055] table 3

[0056]

[0057] After measuring the materials in the above components, add them to the dissolution container with a heating jacket, raise the temperature to 95°C under stirring (50 rpm), mix and dissolve for 2 hours, and keep warm at 90°C for 30 minutes, then cool down to room temperature The material is ready for use. It is a finishing agent for polyvinyl alcohol non-woven fabrics of the present invention;

[0058] (2) Specification of polyvinyl alcohol non-woven fabric for finishing: 15g / m2;

[0059] (3) padding finishing process (see figure 1 ): release the polyvinyl alcohol non-woven fabric by the unwinding roller 1-1, enter the impregnation tank 1-2 that the finishing agent of embodiment 2 has been adorned throug...

Embodiment 3

[0066] The padding finishing of polyvinyl alcohol nonwoven fabric specifically comprises the following steps:

[0067] (1) The impregnation finishing agent for finishing includes the following components in parts by weight (see Table 5):

[0068] table 5

[0069]

[0070] After measuring the materials in the above components, add them into the dissolution container with a heating jacket, heat up to 95°C under stirring (50 rpm), mix and dissolve for 3 hours, and keep warm at 90°C for 30 minutes, then cool down to room temperature The material is ready for use. It is a finishing agent for polyvinyl alcohol non-woven fabrics of the present invention;

[0071] (2) Specification of polyvinyl alcohol non-woven fabric for finishing: 10g / m2;

[0072] (3) padding finishing process (see figure 1 ): release the polyvinyl alcohol non-woven fabric by the unwinding roller 1-1, enter the impregnation tank 1-2 filled with the finishing agent of embodiment 3 through the guide roller, fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com