An anti-vibration hammer live maintenance robot

A technology of live inspection and anti-vibration hammer, which is applied in the direction of inorganic fertilizers, electrical components, organic fertilizers, etc., can solve problems such as easy damage or scratching of knives, inability to realize anti-vibration hammer inspection, and inability to clean the surface of wires, etc., to achieve fusion Better ice effect, improved ice melting efficiency, better ice melting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

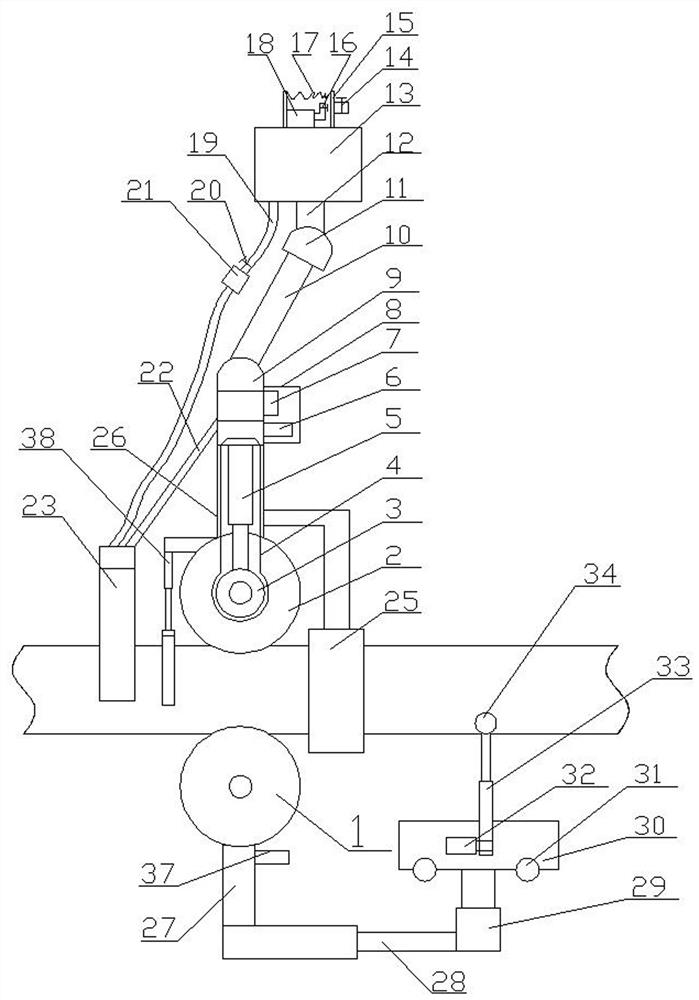

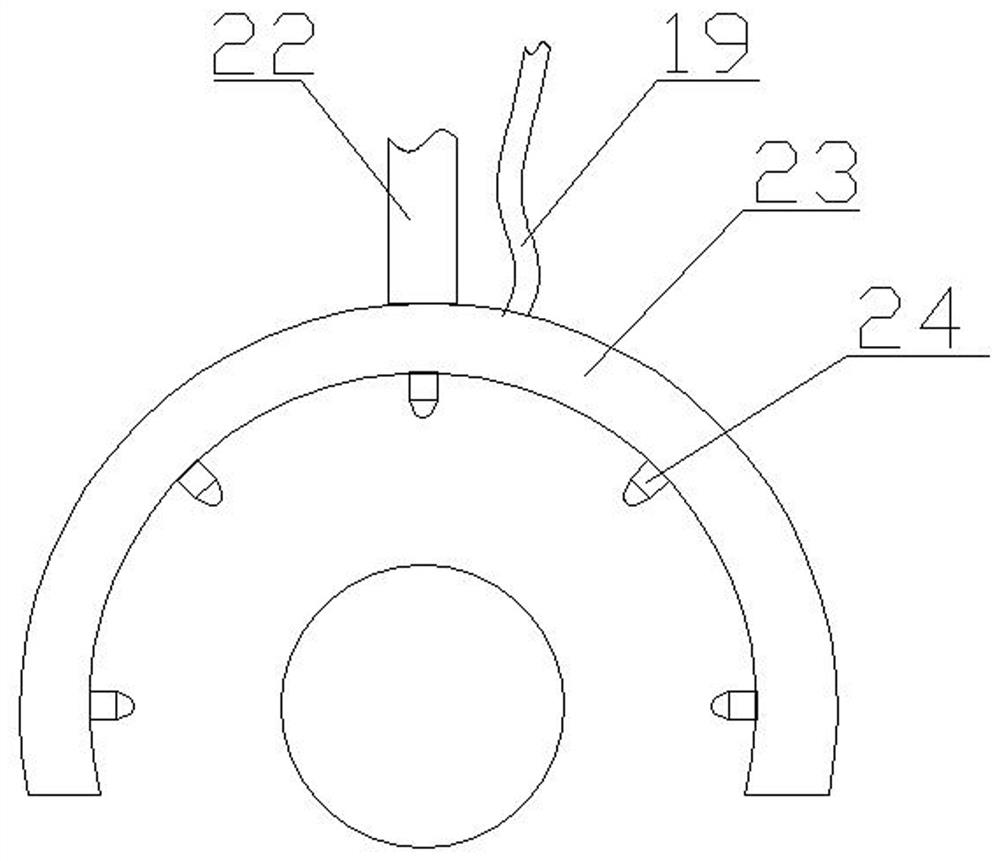

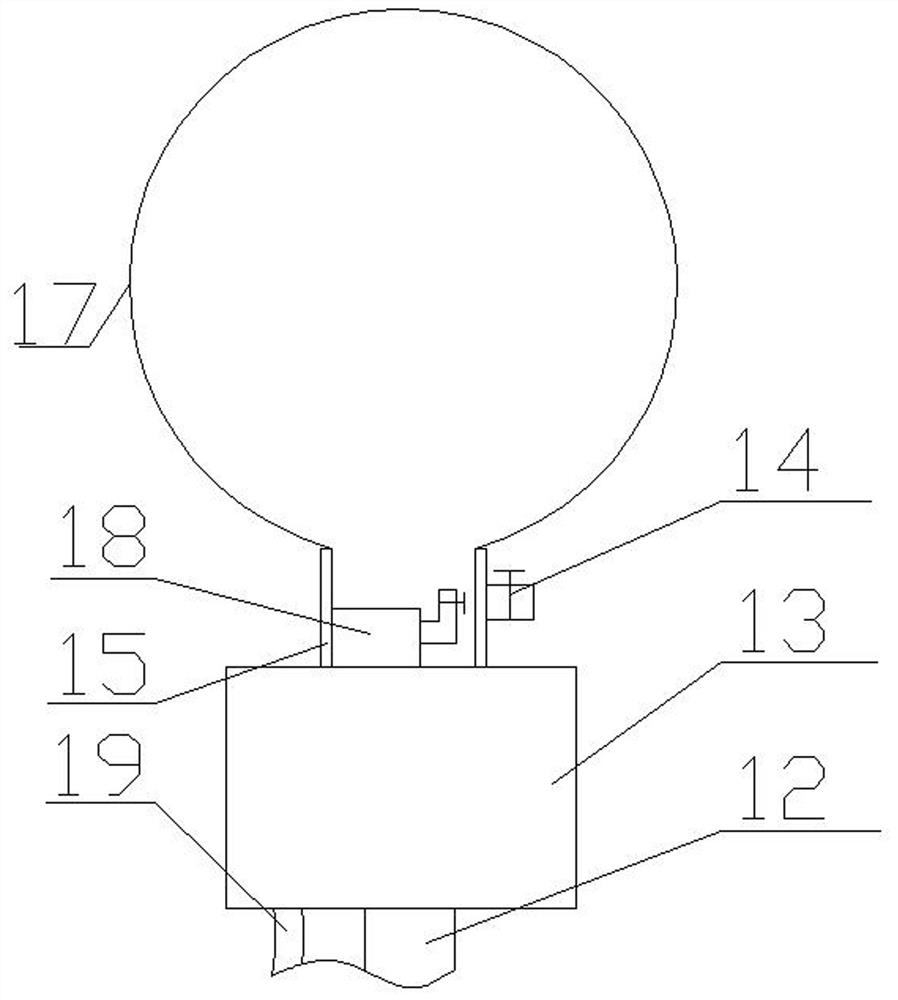

[0046] An anti-vibration hammer live maintenance robot, comprising a mobile carrier, a storage bin 13 arranged on the mobile carrier, a suspension mechanism arranged on the storage bin 13, a The spraying mechanism is arranged on the mobile carrier for overhauling the anti-vibration hammer, the ice shovel mechanism 38 is arranged at the rear of the spraying mechanism, and is arranged on the mobile carrier for controlling the movement The control mechanism of the carrier, the suspension mechanism, the spraying mechanism, the ice-shoveling mechanism 38 and the maintenance mechanism;

[0047] The mobile carrier includes a walking module arranged on the power transmission line, a current transformer 25 arranged on the walking module, and a first electrostatic shielding net 4 arranged on the walking module;

[0048] The lower end of the storage bin 13 is provided with a storage material support rod 12, the lower end of the storage material support rod 12 is provided with a first clo...

Embodiment 2

[0064] This embodiment provides an anti-vibration hammer live maintenance robot. The difference from Embodiment 1 is that the deicing agent in Embodiment 1 is provided, which is made of the ingredients and parts by weight shown in Table 1. The modified Calcium organic acid is made from the ingredients shown in Table 2 and their amounts.

[0065] Wherein, the coupling agent is silane coupling agent KH550. The surfactant is polyoxyethylene lauryl ether.

[0066] The preparation method of described modified organic acid calcium is:

[0067] S1: Add calcium oxide to the bamboo vinegar, stir at room temperature at a speed of 300r / min for 15min to obtain calcium organic acid;

[0068] S2: Add montmorillonite and coupling agent sequentially to the phosphoric acid solution with a mass fraction of 6%, heat in a water bath at 55-60°C, set the rotation speed at 200r / min and stir for 10min, then add sodium polyphosphate, keep the temperature and rotation speed constant Change, continue t...

Embodiment 3

[0072] This embodiment provides an anti-vibration hammer live maintenance robot. The difference from Embodiment 1 is that the deicing agent in Embodiment 1 is provided, which is made of the ingredients and parts by weight shown in Table 1. The modified The consumption of each composition in the calcium organic acid, is with embodiment 2.

[0073] Wherein, the coupling agent is silane coupling agent KH560. The surfactant is alkylphenol polyoxyethylene ether. The preparation method of the modified calcium organic acid is the same as in Example 2. The preparation method of described deicing agent is with embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com