Hydrocracking catalyst as well as preparation method and application thereof

A hydrocracking and catalyst technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of catalytic activity to be improved, achieve uniform distribution of active metals, improve utilization rate, and low preparation cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

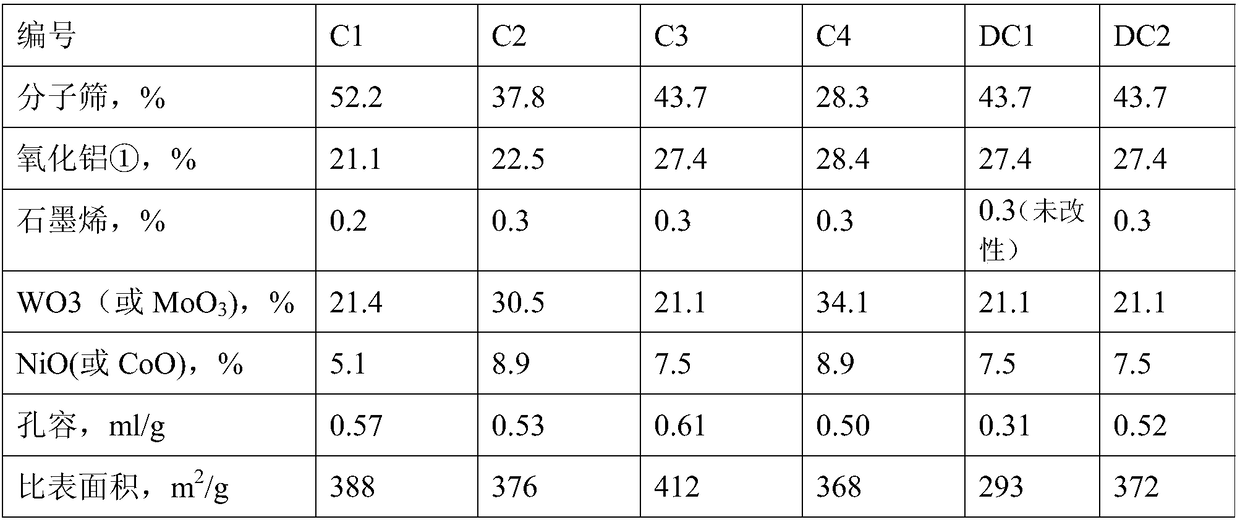

Examples

preparation example Construction

[0022] A method for preparing a hydrocracking catalyst provided by an aspect of the embodiments of the present invention includes:

[0023] 1) Carry out water vapor spray modification treatment to graphene, obtain modified graphene;

[0024] 2) mixing the aluminum hydroxide dry rubber powder with the modified graphene obtained in step 1) to obtain a carrier;

[0025] 3) The aqueous solution of the precursor of the metal active component is provided as the impregnating solution, the precursor of the metal active component is selected from water-soluble compounds containing Group VIB and / or Group VIII metal elements, and the metal active component is selected from metal oxide, then impregnating the carrier obtained in step 2) in the impregnating solution, and then performing microwave drying to obtain a mixture of loaded metal components;

[0026] 4) uniformly mixing the mixture of loaded metal components obtained in step 3) with molecular sieves, and performing rolling, moldin...

Embodiment 1

[0087] Thickness 2.0nm, particle size 2.5μm, specific surface area 750m 2 2.1 g of graphene powder per gram was sprayed and modified with water vapor at 0.25 MPa and 100° C. for 5 minutes to obtain bulky modified graphene. Mix this modified graphene with 200g of aluminum hydroxide dry rubber powder, and use the above prepared tungsten-nickel impregnation solution, the concentration is 27.0g metal (calculated as oxide) / 100mL solution, the impregnation temperature is 25°C, liquid-solid The ratio is 4:1, impregnating aluminum hydroxide dry rubber powder mixed with modified graphene, the impregnation time is 7.0 hours, and microwave drying at 150 ° C for 5 hours, and crushed into 180 meshes to obtain the modified graphene containing metal components. Graphene aluminum hydroxide dry rubber powder mixture (that is, the mixture of the above-mentioned loaded metal components, the dry basis is 72.3%).

[0088] Get the above-mentioned modified graphene aluminum hydroxide dry rubber pow...

Embodiment 2

[0090] The thickness is 2.5nm, the particle size is 1.8μm, and the specific surface area is 600m 2 2.0 g of graphene powder per gram was sprayed and modified with water vapor at a pressure of 0.18 MPa and 150° C. for 3 minutes to obtain bulky modified graphene. Mix this modified graphene with 200g of aluminum hydroxide dry rubber powder, and use the prepared molybdenum-cobalt impregnation solution, the concentration is 22.3g metal (calculated as oxide) / 100mL solution, the impregnation temperature is 20°C, and the liquid-solid ratio 6:1, impregnated aluminum hydroxide dry rubber powder mixed with modified graphene, the impregnation time was 2 hours, and dried in microwave at 100°C for 10 hours, and crushed into 180 meshes to obtain modified graphite containing metal components Aluminum hydroxide dry rubber powder mixture (that is, the mixture of metal-loaded components mentioned above, the dry basis is 69.1%).

[0091] Get the above-mentioned modified graphene aluminum hydroxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com