Food-grade self-leveling temperature-resisting sealant and preparation method thereof

A self-leveling and sealant technology, applied in chemical instruments and methods, adhesives, and other chemical processes, etc., can solve problems such as water resistance, adhesiveness not mentioned, easy aging, yellowing, and production of harmful substances, etc. Improve waterproof sealing and bonding strength, improve self-leveling, good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

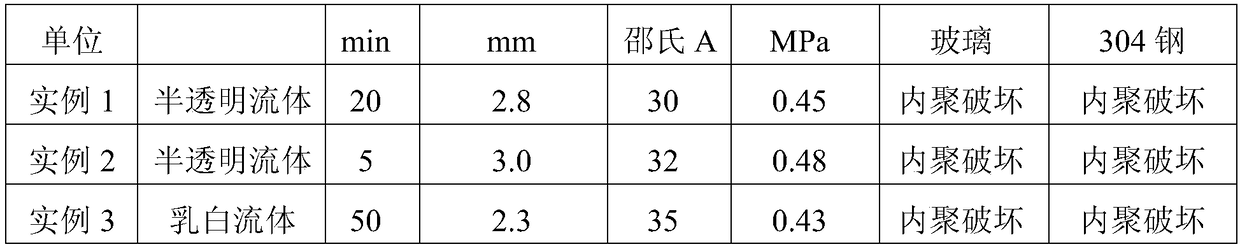

no. 1 example

[0023] The viscosity of α, ω-dihydroxy polydimethylsiloxane at room temperature is 25°C is 20000mPa·s, and the dosage is 100 parts;

[0024] The plasticizer is dimethyl polysiloxane, and the consumption is 5 parts;

[0025] The filler is hydrophilic fumed silica, and the dosage is 4 parts;

[0026] The crosslinking agent is methyltrimethoxysilane, and the dosage is 6 parts;

[0027] The adhesion promoter is a mixture A of 0.3 parts of 3-aminopropyltriethoxysilane mixed with 0.6 parts of γ-(2,3-epoxypropoxy)propyltrimethoxysilane;

[0028] The catalyst is tert-butyl titanate, and the dosage is 2 parts.

[0029] The preparation steps are as follows:

[0030] (1) α, ω-dihydroxy polydimethylsiloxane, dimethylpolysiloxane and hydrophilic fumed silica were stirred in a double planetary mixer for 120 minutes, the rotating speed was 30 rpm, and the temperature was 110℃, vacuum -0.8Mpa;

[0031] (2) Lower the temperature to 20-55°C, add methyltrimethoxysilane, mixture A and tert-b...

no. 2 example

[0034] The amount of α, ω-dihydroxy polydimethylsiloxane with a viscosity of 20000mPa·s is 80 parts, and the amount of α, ω-dihydroxy polydimethylsiloxane with a viscosity of 5000mPa·s is 20 parts;

[0035] The filler is hydrophobic fumed silica, and the dosage is 4 parts;

[0036] The crosslinking agent is methyltriacetoxysilane, and the dosage is 9 parts;

[0037] The adhesion promoter is γ-(2,3-epoxypropoxy)propyltrimethoxysilane, and the dosage is 0.3 parts;

[0038] The catalyst is tert-butyl titanate, and the dosage is 0.3 parts.

[0039] The preparation steps are as follows:

[0040] (1) α, ω-dihydroxy polydimethylsiloxane and hydrophobic fumed silica were stirred for 120 minutes in a double planetary mixer at a speed of 30 rpm, a temperature of 115°C, and a vacuum of -0.8Mpa;

[0041] (2) Lower the temperature to 20-55°C, add methyltriacetoxysilane and tert-butyl titanate into a planetary mixer, stir for 30 minutes at a speed of 40 rpm, control the temperature at 40...

no. 3 example

[0044] The viscosity of α, ω-dihydroxy polydimethylsiloxane at room temperature is 25°C is 80000mPa·s, and the dosage is 80 parts;

[0045] The plasticizer is dimethyl polysiloxane, and the consumption is 20 parts;

[0046] The filler is hydrophilic fumed silica, and the dosage is 4 parts;

[0047] The cross-linking agent is a mixture B of 5 parts of vinyl tributylketoxime silane mixed with 4 parts of methyl tributylketone oxime silane;

[0048] The adhesion promoter is a mixture C of 0.3 parts of γ-(2,3-epoxypropoxy)propyltrimethoxysilane and 0.6 parts of 3-aminopropyltriethoxysilane;

[0049] The catalyst is tert-butyl titanate, and the dosage is 1.5 parts.

[0050] The preparation steps are as follows:

[0051] (1) α, ω-dihydroxy polydimethylsiloxane, dimethylpolysiloxane and hydrophilic fumed silica were stirred in a double planetary mixer for 120 minutes, the rotating speed was 30 rpm, and the temperature was 110℃, vacuum -0.8Mpa;

[0052] (2) Lower the temperature t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com