Modified lithium-rich manganese-based anode material and preparation method thereof

A lithium-rich manganese-based, positive electrode material technology, applied in the direction of battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of undeveloped improvement, achieve the effect of simple and easy to control, reduce oxygen evolution of materials, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The chemical formula of the modified lithium-rich manganese-based positive electrode material is: Li 2 mn 0.5 V 0.5 o 2 F, the valence of the V element is +4, and the valence of the Mn element is +2.

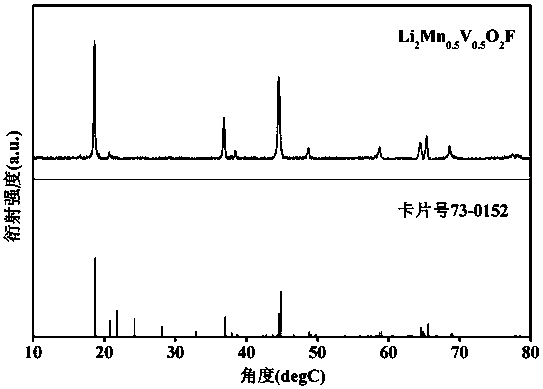

[0037] Depend on figure 1 It can be seen that the Li 2 mn 0.5 V 0.5 o 2 The main diffraction peak of F and Li 2 MnO 3 The main peaks of the standard card 73-0152 overlap, proving that the synthesized material structure and Li 2 MnO 3 similar, and the Li 2 mn 0.5 V 0.5 o 2 The experimental results of the ICP-AES element content of F are consistent with the design target value, as shown in Table 1.

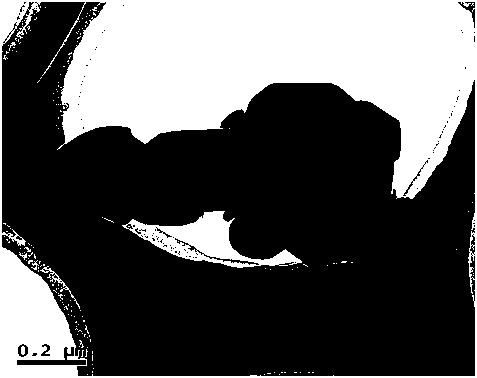

[0038] Depend on figure 2 It can be seen that the Li 2 mn 0.5 V 0.5 o 2 F is a spherical particle with a particle diameter of 200-300nm.

Embodiment 1-1

[0040] (1) 1.42g (0.02mol) of manganese oxide, 1.66g (0.02mol) of vanadium dioxide, 1.04g (0.04mol) of lithium fluoride and 0.62g (0.0208mol) of lithium oxide (2% excess lithium compared to the theoretical amount) ) is uniformly mixed in a solid state to obtain mixture A;

[0041] (2) The mixture A obtained in step (1) is placed in a planetary ball mill under a protective atmosphere of high-purity argon, and ball milled for 24 hours at a revolution speed of 300r / min and an autorotation speed of 600r / min to obtain a modified Lithium-rich manganese-based cathode material Li 2 mn 0.5 V 0.5 o 2 F.

[0042] Battery assembly: the gained 2g Li of the embodiment of the present invention 2 mn 0.5 V 0.5 o 2 F is used as the positive electrode, and 0.25g conductive agent Super-P and 0.25g binder polyvinylidene fluoride are placed in N-methylpyrrolidone solvent dispersant, and mixed into a homogeneous slurry by using a high-speed homogenizer. The micron-scale adjustable membrane ...

Embodiment 1-2

[0046] (1) 2.86g (0.02mol) manganese oxalate, 1.66g (0.02mol) vanadium dioxide, 1.04g (0.04mol) lithium fluoride and 2.80g (0.0424mol) lithium acetate (3% excess lithium compared to theoretical ), mixed uniformly in a liquid phase with a mass ratio of total solids to ethanol of 1:1 to obtain mixture A;

[0047] (2) The mixture A obtained in step (1) is placed in a muffle furnace under the protective atmosphere of high-purity nitrogen gas, and the temperature is raised to 600 °C at a rate of 6 °C / min, and pre-calcined for 4 hours, and then in high-purity nitrogen gas Under a protective atmosphere, place it in a planetary ball mill, and perform ball milling at a revolution speed of 300r / min and an autorotation speed of 600r / min for 24 hours to obtain the lithium-rich manganese-based positive electrode material Li 2 mn 0.5 V 0.5 o 2 F.

[0048] Battery assembly: same as Example 1-1.

[0049] After testing, the lithium-rich manganese-based positive electrode material Li obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com