Lithium-rich material, modification method and application thereof

A lithium-rich material and modification technology, applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the instability of spinel materials, manganese-based spinel coating layer and element doping, modified lithium-rich Material difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

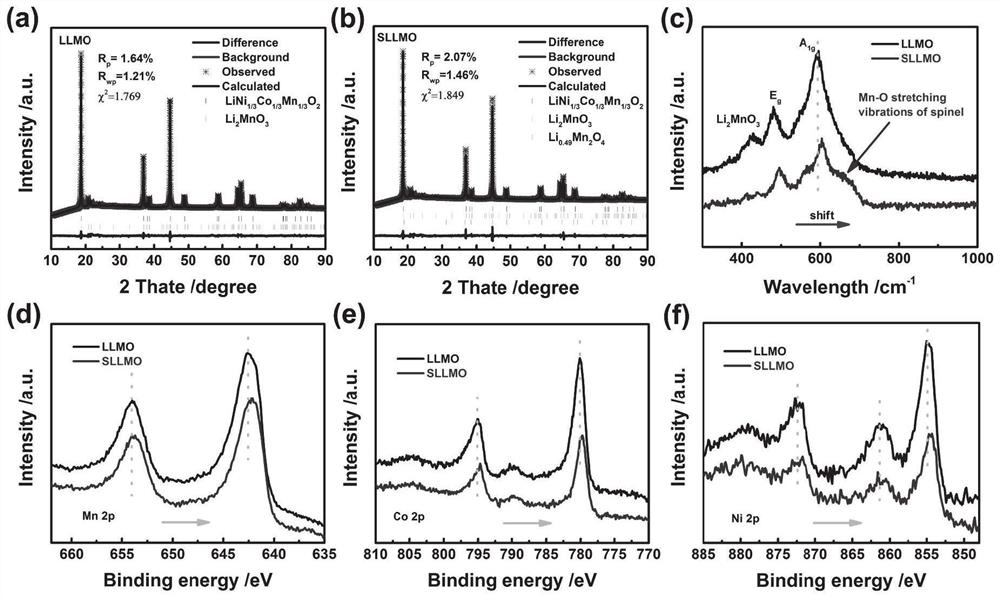

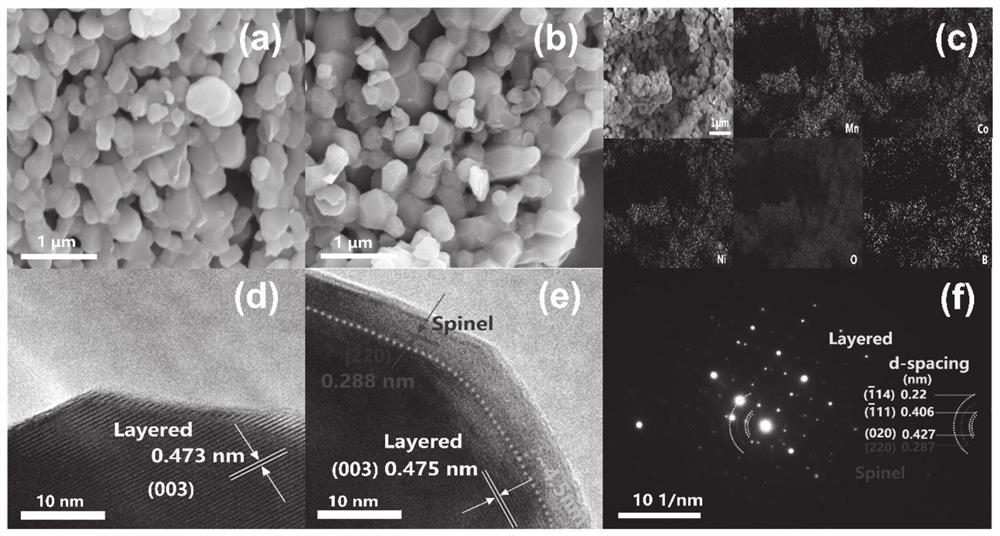

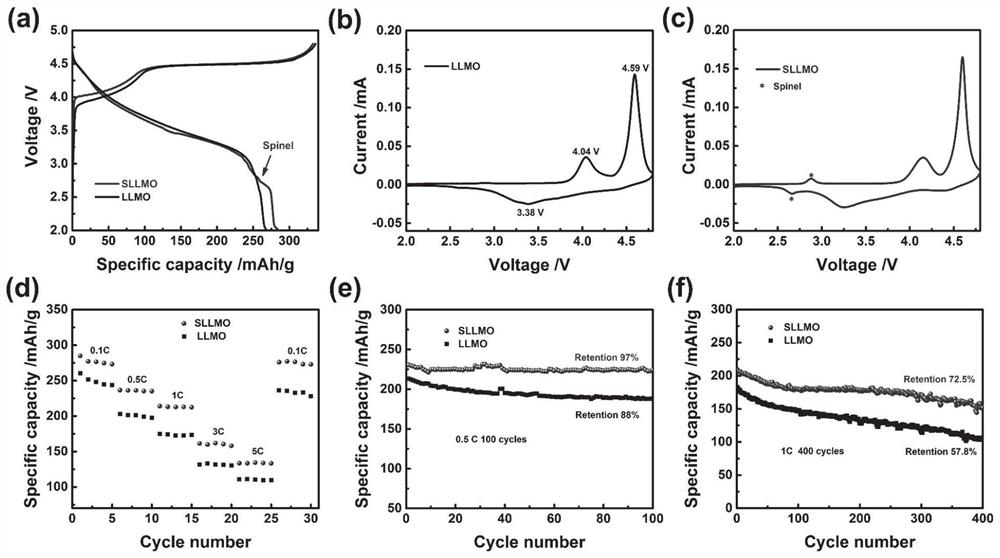

Method used

Image

Examples

Embodiment 1

[0056] Step 1: Take manganese nitrate, cobalt nitrate, nickel nitrate, and lithium nitrate, dissolve them in 30ml deionized water at a molar ratio of 0.54:0.13:0.13:1.2, dissolve citric acid in another 30ml deionized water, and mix citric acid with metal cations The molar ratio is 2:1;

[0057] Step 2: Add the citric acid solution to the metal salt solution, magnetically stir overnight at a stirring speed of 500 rpm, then evaporate the solvent to dryness, and place the obtained material in a muffle furnace for calcination at 900°C for 12 hours;

[0058] Step 3: Dissolve bis(catechol)diboronic acid ester in nitrogen methyl pyrrolidone solution, the concentration of bis(catechol)diboronic acid ester is 20mg / ml, then disperse 10g of lithium-rich manganese-based material into 100ml of this solution was heated to 100°C, stirred overnight at 500rpm, then centrifugally filtered several times, and then calcined at 500°C for 6h to obtain a lithium-rich manganese-based material modified...

Embodiment 2

[0064] Step 1: get the mol ratio of manganese sulfate, cobalt sulfate, nickel sulfate 0.54:0.13:0.13 to be dissolved in 100ml deionized water, sodium carbonate is dissolved in 100ml deionized water, the mol ratio of sodium carbonate and metal cation is 1.5:1, in The pH is controlled at about 7.5, and the co-precipitation experiment is carried out under the reaction conditions of 50°C;

[0065] Step 2: After drying the obtained precipitate, mix it with lithium acetate (the molar ratio of lithium acetate: manganese sulfate: cobalt sulfate: nickel sulfate is 1.2:0.54:0.13:0.13), and then calcinate at 900°C for 12 hours to obtain a lithium-rich manganese-based material ;

[0066] Step 3: Disperse 100 mg of lithium-rich manganese-based material into a nitrogen-methylpyrrolidone solution containing 20 mg of bis(catechol)diboronic acid ester, and then undergo a heating reaction, the heating temperature is 100°C, and the reaction time is 24h), After centrifugation and vacuum drying, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com