Carbon material and method for manufacturing same

A manufacturing method and technology of carbon materials, applied in the direction of chemical instruments and methods, nano-carbon, carbon compounds, etc., can solve the problems of adding new functions, complicated manufacturing conditions, etc., and achieve the effect of excellent electron transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

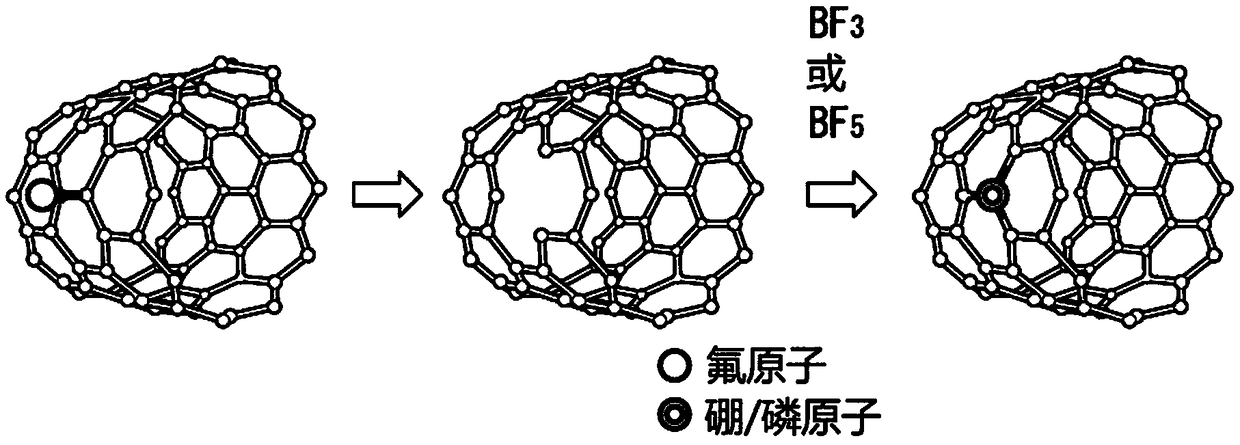

[0049] Embodiment 1 of the present invention will be described below. figure 1 It is an explanatory drawing for explaining the manufacturing method of the carbon material concerning Embodiment 1 of this invention. figure 2 It is an explanatory diagram showing a production process when a nitrogen-containing carbon material is used as a raw material in the production method of the carbon material according to the first embodiment.

[0050] Such as figure 1 and figure 2 As shown, the carbon material related to Embodiment 1 can be produced by the following production method, which includes at least the following steps: the process of subjecting the surface of the carbon material as a raw material to fluorination treatment; the carbon material after the fluorination treatment A process of boriding and / or phosphating.

[0051] Examples of the carbon material as the raw material include carbon materials having a carbon skeleton composed of carbon atoms, preferably carbon materia...

Embodiment approach 2

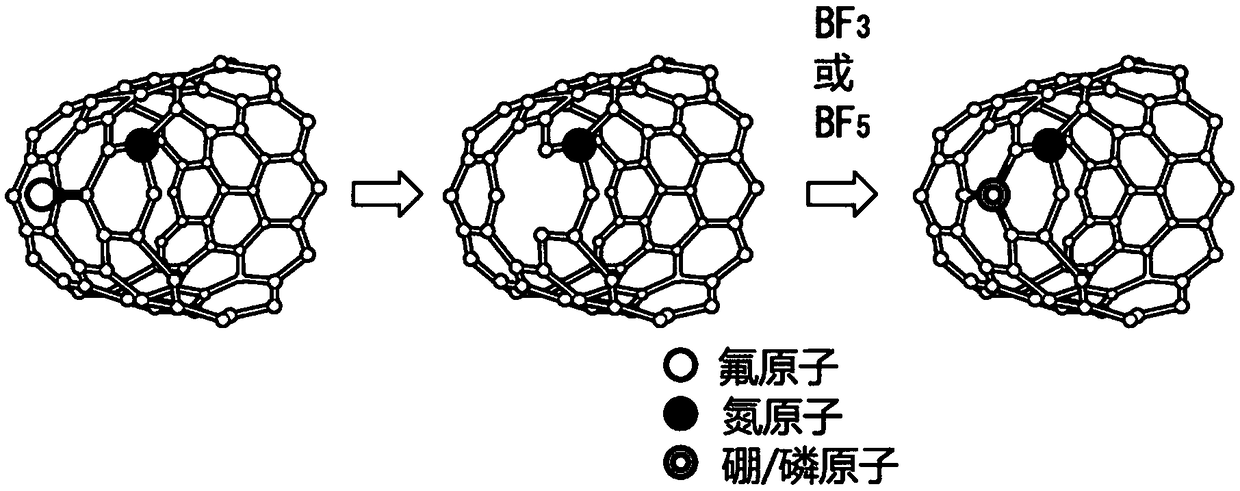

[0087] The method for producing a carbon material according to Embodiment 2 of the present invention will be described below.

[0088] The method for producing a carbon material according to Embodiment 2 is different in that after the fluorination treatment step, and before the boridation treatment and / or phosphating treatment, the carbon material after the fluorination treatment is subjected to nitriding treatment.

[0089] The step of performing the nitriding treatment is a step of introducing nitrogen atoms into the carbon material in the gas phase by bringing a nitriding treatment gas containing at least a nitrogen-containing gas into contact with the carbon material after the fluoridation treatment. In this step, the form of introduction of nitrogen atoms into the carbon material can be changed according to the treatment temperature (details will be described later).

[0090] The nitriding gas is not particularly limited as long as it contains a nitrogen-containing gas, a...

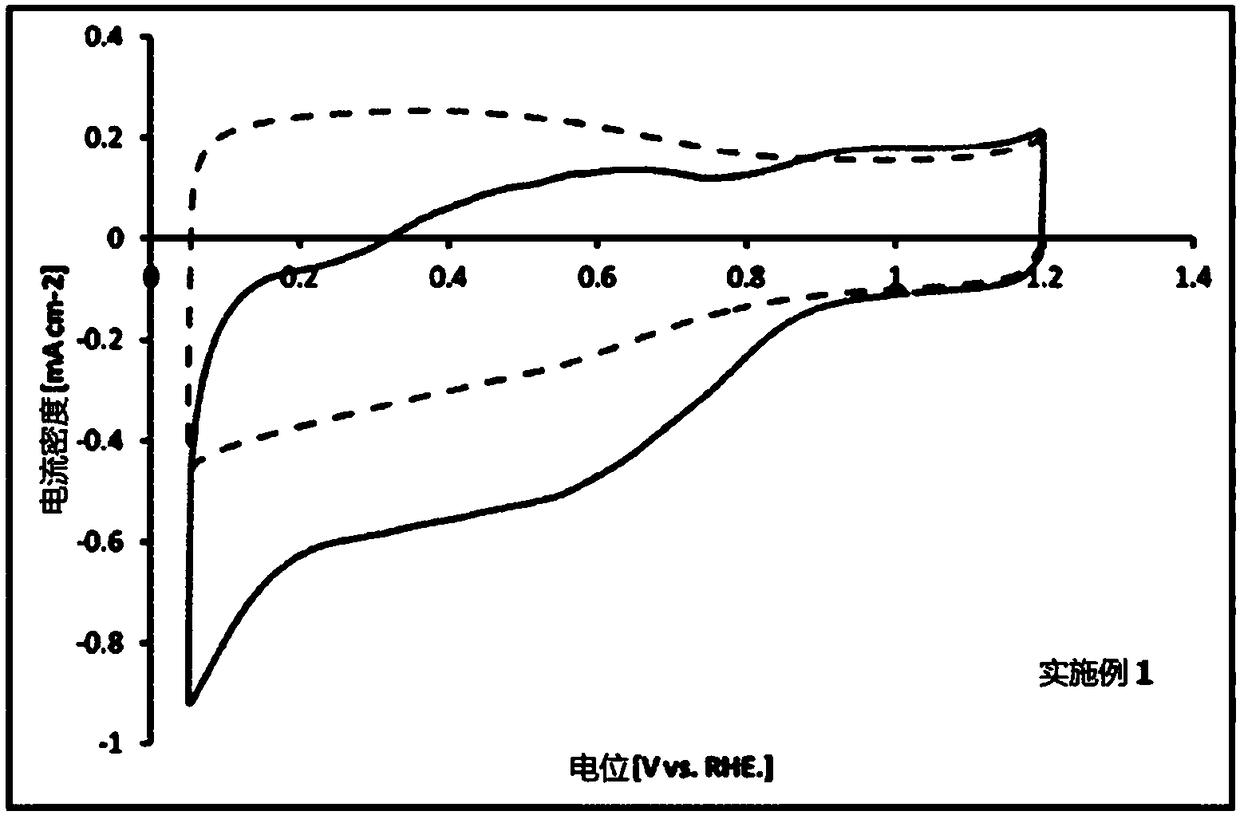

Embodiment 1

[0106] Single-walled carbon nanotubes (10 mg) were introduced into a PTFE (polytetrafluoroethylene) container (capacity 5 mL), and the container was placed in an electropolished SUS316L chamber (capacity 30 mL). Furthermore, the indoor vacuum was replaced with nitrogen, and the temperature was raised to 250° C. at 4° C. / min under a nitrogen flow (20 mL / min), and a constant temperature treatment was performed for 2 hours.

[0107] Next, the vacuum was replaced with a fluorinated treatment gas diluted with nitrogen to 20 vol % of fluorine gas, and flowed in the chamber at a flow rate of 25 mL / min. Furthermore, the temperature in the chamber was raised to 250° C. at 4° C. / min, and a fluorination treatment was performed for 4 hours. Thereafter, the vacuum in the chamber was replaced with nitrogen, and the chamber was naturally cooled to room temperature under a nitrogen flow (20 mL / min), and the fluorinated single-walled carbon nanotubes were taken out.

[0108] Next, the fluorin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com