Method for producing activated coke without coal tar by utilizing vertical carbonization furnace

A technology for activated coke and carbonization furnace, applied in chemical instruments and methods, coke ovens, petroleum industry, etc., can solve the problems of low strength of granular billets, combustion products, pollution of the environment, etc., and achieve short carbonization time, low carbonization temperature, and economical The effect of natural resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

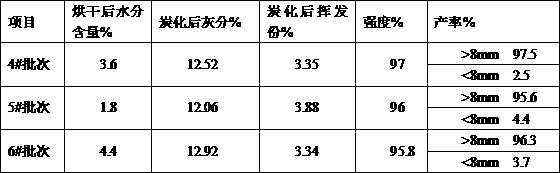

Examples

Embodiment Construction

[0016] In order to more clearly illustrate the technical solutions of the embodiments of the present invention, further description will be made below in conjunction with the embodiments.

[0017] The embodiment of the present invention provides a method for producing activated coke without coal tar added by using a vertical carbonization furnace, which is characterized in that it includes the following steps:

[0018] Ingredients: The raw material is composed of coke powder, anthracite, coking coal, bituminous coal, asphalt powder, and binder, wherein coke powder (ie blue carbon powder) and anthracite account for 55% of the total weight of the powder %, coking coal accounts for 35% of the total weight of the powder, bituminous coal accounts for 5% of the total weight of the powder, pitch accounts for 5% of the total weight of the powder, and the binder is prepared according to 3%:97% of the total weight of the powder to form mixed powder;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com