Degradable dust inhibitor for inhibiting and controlling air suspended particulate matters in urban public space

A technology of air suspension and dust suppressant, applied in climate change adaptation, other chemical processes, chemical instruments and methods, etc., can solve problems such as limited means, and achieve the effect of improving effect and flexible environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Preparation of dust suppressant

[0031] 1. Solution type dust suppressant

[0032]Weigh natural high molecular polymers with different molecular weights according to Table 1-3, add a small amount of ethanol to help disperse evenly, and dissolve with water, and prepare solutions with corresponding mass concentrations, and adjust the pH of the final solution to 5-8 if necessary:

[0033] For Dust Suppressant No. 4, weigh 0.03 g of polyglutamic acid with a molecular weight of 4000 kDa, add 2 mL of ethanol and stir to disperse without agglomeration, then add 98 mL of 0.01 mM pH7.4 PBS buffer solution while stirring to achieve complete dissolution , that is;

[0034] For Dust Suppressant No. 6, weigh 0.5 g of pullulan with a molecular weight of 200 kDa, add 5 mL of ethanol and stir to disperse without agglomeration, then add about 95 mL of water to dissolve completely while stirring, and obtain it;

[0035] Dust suppressant No. 10, weigh 0.1 g of chitosan with a...

Embodiment 2

[0046] Example 2 Corrosion test of dust suppressant

[0047] Take representative metals, plastics, stones, glass, etc. to make discs with a diameter of about 5 cm and a thickness of 0.1 cm. Different materials were soaked separately. Three pieces of the same material were soaked in 200 mL of dust suppressant solution for 72 hours. After taking them out, they were rinsed with distilled water to remove loose corrosion products, wiped dry or blown dry with cold wind, and weighed the material pieces before and after soaking. Mass, take the average value of 3 slices to calculate the corrosion rate.

[0048] Corrosion rate = (mass before immersion - mass after immersion) / (sample area × test period)

[0049] Mass before immersion (g); Mass after immersion (g); Sample area (m 2 ); test period (h)

[0050] Referring to the corrosion grade of aluminum alloy materials, the corrosion rate is 0.003-0.031 g / m 2 When h is a corrosion-resistant aluminum alloy, the corrosion resistance i...

Embodiment 3

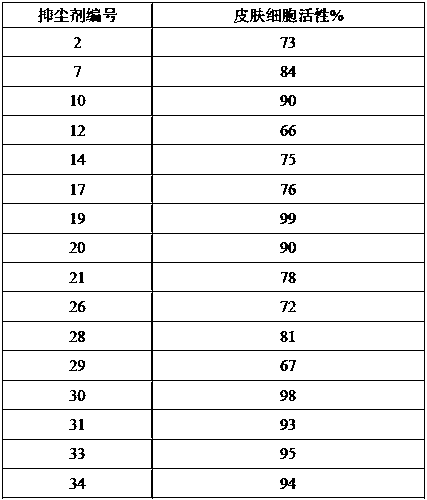

[0054] Example 3 In vitro test of skin irritation of dust suppressant

[0055] Choose EpiSkin TM The human skin model kit was pre-cultured according to the operation method in the manual, and 5% SDS (positive control) and 10 μL of the dust suppressant to be tested were applied to the surface of the artificial skin respectively. After acting for 15 minutes, the test substance was removed, and the incubation was continued for 42 hours. Cell viability was detected by MTT assay. Compared with the control group, skin cell activity > 50% indicates that the test substance is not irritating, and skin cell activity ≤ 50% indicates that the test substance is irritating.

[0056] Table 5 Skin irritation test of dust suppressant

[0057]

[0058] The results are shown in Table 5: the skin cell activity of the dust suppressant in Example 1 was >50%, and no obvious skin irritation was seen.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com