Method for extracting cypress essential oil and phytoncide at low temperature and negative pressure

A technology of low-temperature negative pressure and phytoncine, which is applied in the direction of essential oils/fragrances, fat production, etc., can solve the problems of easy volatilization of effective substances, heavy smell of coke gas and phenol, long distillation time, etc., to achieve simple preparation and avoid hydrolysis , Improve the effect of oil outlet area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

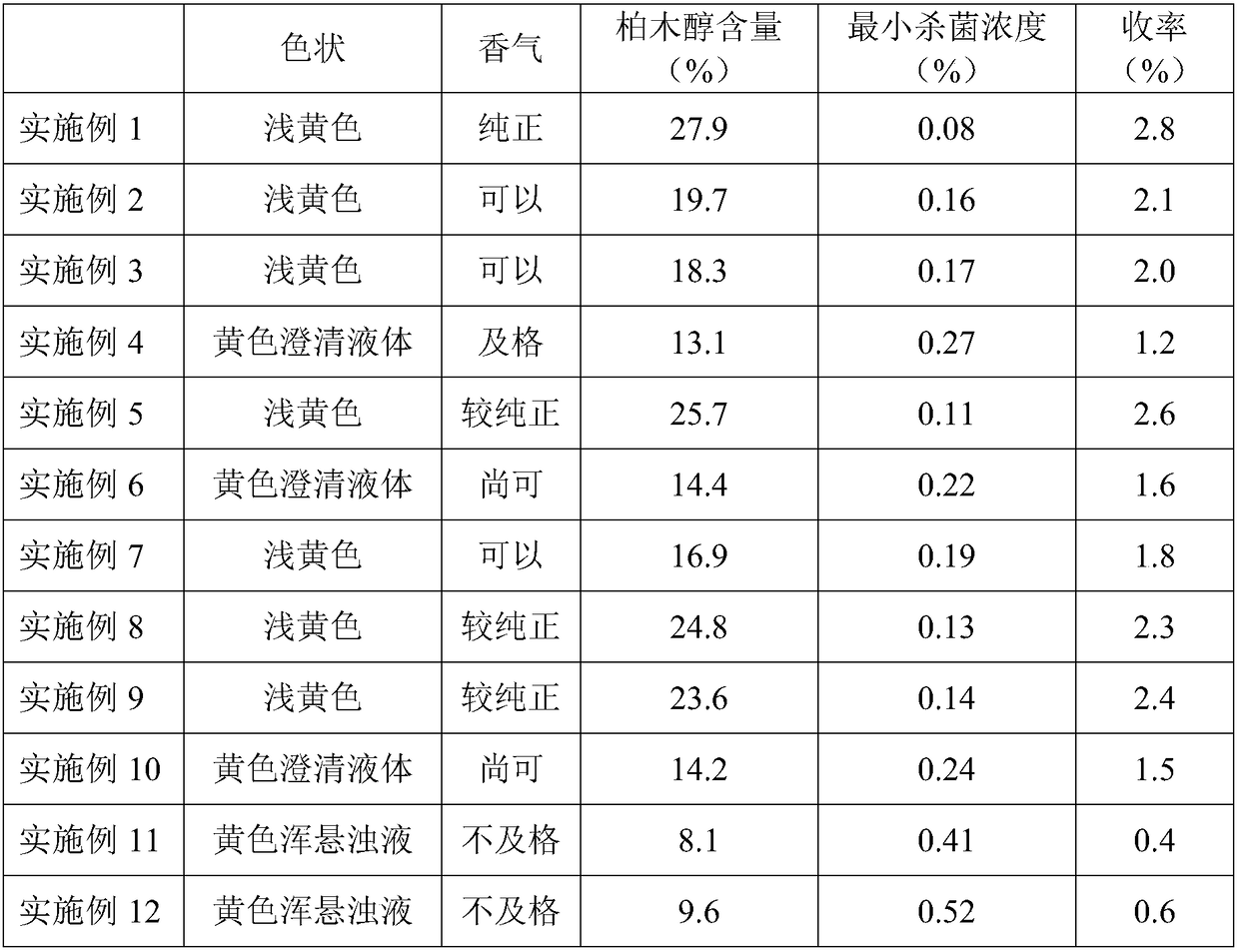

Examples

Embodiment 1

[0076] Embodiment 1 provides a method for low-temperature negative pressure extraction of cypress essential oil and phytondrin, and the preparation process is as follows:

[0077] (1) Pretreatment

[0078] ① Cleaning for the first time: at room temperature, clean the roots of cypress trees over 60 years old with a high-pressure water gun, and wash them three times until no soil appears, and then dry them after cleaning;

[0079] ② Pulverization: use a pulverizer to pulverize the cypress in step ①, and the particle size of the obtained cypress particles is 180-220 μm;

[0080] ③Second cleaning: at room temperature, put the cypress particles obtained in step ② into water and carboxylic acid derivatives for cleaning three times; the volume ratio of the cypress root mass to water is 1:200; The weight ratio of water and carboxylic acid derivatives is 1:0.5;

[0081] ④ Soaking: put the cypress raw material obtained in step ③ into 50°C water and soak for 60 minutes;

[0082] (2) D...

Embodiment 2

[0093] Example 2 provides a method for extracting cypress essential oil and phytondrin under low-temperature negative pressure. The implementation method is the same as that of Example 1, except that the particle size of the cypress particles is 150-250 μm.

Embodiment 3

[0095] Embodiment 3 provides a kind of method of low-temperature negative pressure extraction juniper wood essential oil and phytondrin, and embodiment is the same as embodiment 1, and difference is as follows:

[0096] (1) Pretreatment

[0097] 1. First cleaning: at room temperature, put the roots of juniper trees more than 60 years old in water and wash them three times until no soil appears, then dry them after cleaning; the volume ratio of the roots of juniper trees to water is 1:500;

[0098] ② Pulverization: use a pulverizer to pulverize the cypress in step ①, and the particle size of the obtained cypress particles is 180-220 μm;

[0099] ③Second cleaning: at room temperature, put the cypress particles obtained in step ② into water and carboxylic acid derivatives for cleaning three times; the volume ratio of the cypress root mass to water is 1:450; The weight ratio of water and carboxylic acid derivatives is 1:1;

[0100] ④ Soaking: put the juniper wood raw material o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com