A kind of Gan-based LED electrode structure and manufacturing method thereof

A technology of electrode structure and manufacturing method, which is applied to circuits, electrical components, semiconductor devices, etc., can solve the problems of not mentioning the method of forming the coated electrode, the adhesion is not ideal, and the cost of the electrode structure is high, so as to prevent mutual The effect of diffusing, reducing light absorption, and improving luminous brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

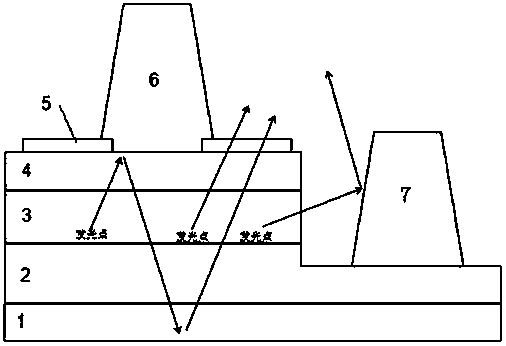

[0046] (1) Evaporation ITO thin film on the p-type GaN layer 4 of sapphire wafer 8 (GaN-based LED wafer) using electron beam evaporation table, the ITO thin film thickness is 600 angstroms, and annealing is carried out, and the sheet resistance obtained is lower than 30 ohms / Port, the ITO thin film layer with a transmittance greater than 85% (ie the ITO current spreading layer 5). Make a mask pattern through photoresist to obtain an ITO pattern, etch the N region to the n-type GaN layer 2 to form a mesa on the n-type GaN layer 2 .

[0047] (2) Making photolithographic electrode patterns to form a coated electrode structure

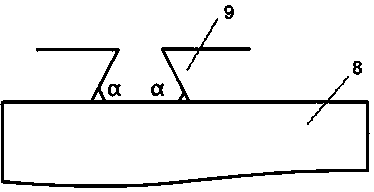

[0048] ① Coating: use negative photoresist 9 (see image 3 ) on the wafer surface to carry out the gluing step, the thickness of the gluing is 10000 angstroms, and the gluing speed is 1600rpm; the wafer that has been coated with gluing is placed on a hot plate (or other contact heating equipment) for preliminary drying (pre-baking), The temperature is t...

Embodiment 2

[0063] (1) With embodiment 1.

[0064] (2) Making photolithographic electrode patterns.

[0065] ①Glue application: use negative photoresist to apply glue on the surface of the wafer, the thickness of the glue is 35000 angstroms, and the speed of glue coating is 3000rpm; the coated wafer is preliminarily dried, and the temperature is controlled between 120°C. The time is between 120 seconds.

[0066] ②Exposure: Expose the wafer that has completed step ①. The exposure time is 25 seconds, and the exposure power is 500w.

[0067] ③Development: The wafer that has completed step ② is developed. The development time is 90 seconds, the temperature of the developer is 70°C, and the temperature is kept constant. After the development is completed, the wafer is baked for the third time. The temperature is 120°C and the time is 120 Second.

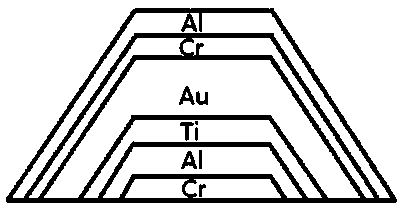

[0068] (3) Making electrode structure

[0069] 1. with embodiment 1;

[0070] ② Evaporation of the first Cr layer: After the chamber reaches th...

Embodiment 3

[0077] Increase the thickness of the first Cr layer and the second Cr layer to 200 Angstroms.

[0078] (1) With embodiment 1.

[0079] (2) Making photolithographic electrode patterns

[0080] ① Glue coating: use negative photoresist to coat the surface of the wafer with a coating thickness of 20,000 angstroms and a speed of 2,000 rpm; preliminarily dry the coated wafer at a temperature of 100°C for 100 seconds .

[0081] ②Exposure: Expose the wafer that has completed step ①. The exposure time is 15 seconds and the exposure power is 400w.

[0082] ③Development: The wafer that has completed step ② is developed. The development time is 70 seconds, the temperature of the developer is 60°C, and the temperature is kept constant. After the development is completed, the wafer is baked for the third time. The temperature is 120°C and the time is 120 Second.

[0083] (3) Making electrode structure

[0084] ① Same as Example 1.

[0085] ② Evaporation of the first Cr layer: After th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com