Dinotefuran suspending agent and preparation method thereof

A technology for dinotefuran and suspoemulsion, which is applied in the field of dinotefuran suspoemulsion and its preparation, can solve the problems of creaming or sanding with large particle size, and achieves the effects of strong permeability, resistance to rainwater erosion, and reduction of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] On the other hand, the embodiments of the present invention provide a preparation method of dinotefuran suspoemulsion, which includes the following components in the following weight percentages based on the total weight of the dinotefuran suspoemulsion: 5% to 100% of the dinotefuran suspoemulsion 25%; non-aqueous solvent 15% ~ 40%; emulsifier 5% ~ 15%; wetting and dispersing agent 2% ~ 4%; thickener 1% ~ 3%; antifreeze 2% ~ 5%; preservative 0.1 %~0.3%; water balance;

[0037] The content of the formulation components in the dinotefuran suspoemulsion and its preference are as described above, such as, in some embodiments, the dinotefuran suspoemulsion also includes a second active ingredient, and the second active The ingredients account for 5% to 30% of the total weight of the dinotefuran suspoemulsion.

[0038] Specifically, the second active ingredient may be selected from at least one of pyriproxyfen, bifenthrin, lambda-cyhalothrin and chlorpyrifos.

[0039] In so...

Embodiment 1

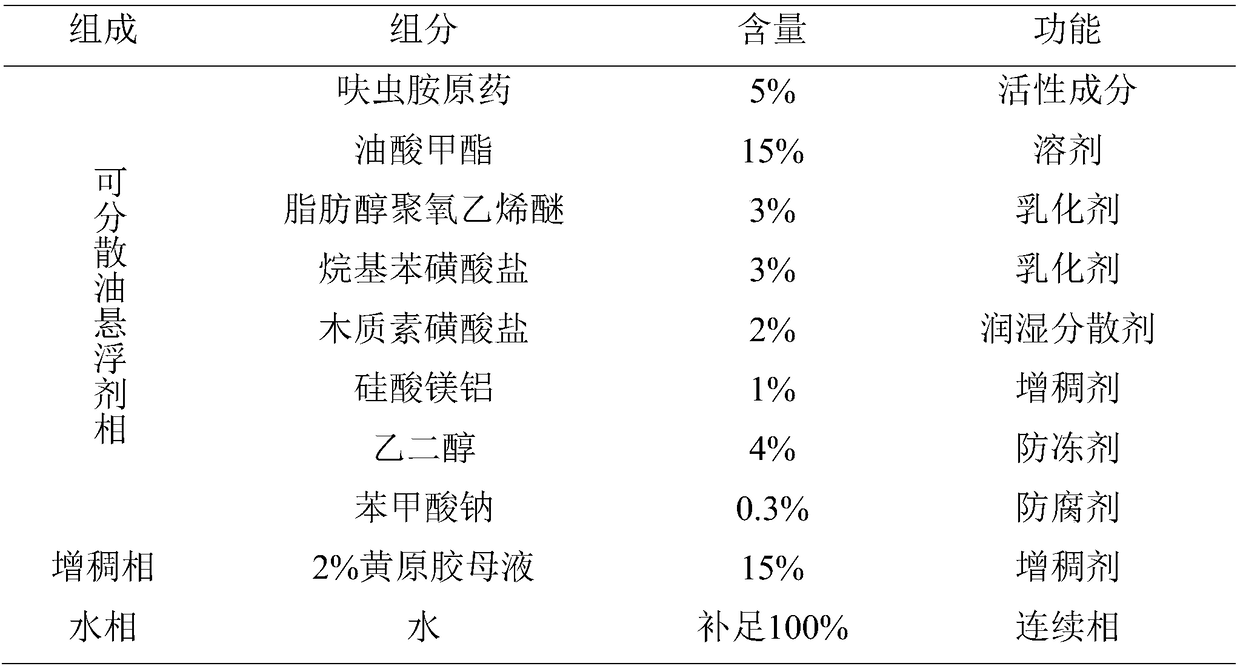

[0068] A dinotefuran suspoemulsion comprising the components shown in Table 1 below.

[0069] Table 1

[0070]

[0071] The preparation method of described dinotefuran suspoemulsion comprises the following steps:

[0072] According to the components in the above table, weigh the components except 2% xanthan gum mother liquor and water, mix, sand mill and filter to obtain a dispersible oil suspension concentrate with a particle size of 1 μm to 5 μm;

[0073] Add the above dispersible oil suspension to water and keep stirring, or add water to the above dispersible oil suspension and keep stirring to obtain an O / W suspoemulsion;

[0074] Add 2% xanthan gum mother liquor into the above O / W suspoemulsion, and stir evenly to obtain 5% dinotefuran suspoemulsion.

Embodiment 2

[0076] A dinotefuran suspoemulsion comprising the components shown in Table 2 below.

[0077] Table 2

[0078]

[0079] The preparation method of described dinotefuran suspoemulsion comprises the following steps:

[0080] According to the components in the above table, weigh the components except 2% xanthan gum mother liquor and water, mix, sand mill and filter to obtain a dispersible oil suspension concentrate with a particle size of 1 μm to 5 μm;

[0081] Add the above dispersible oil suspension to water and keep stirring, or add water to the above dispersible oil suspension and keep stirring to obtain an O / W suspoemulsion;

[0082] Add 2% xanthan gum mother liquor to the above O / W suspoemulsion, and stir evenly to obtain 10% dinotefuran suspoemulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com