Single-phase nano silver copper alloy solid solution welding paste and preparation method thereof

A nano-silver and copper alloy technology, applied in the field of materials, can solve the problems of poor oxidation stability of nano-copper solder paste, achieve strong anti-electromigration and anti-electrochemical migration, strong anti-oxidation ability, huge development potential and application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0030] A single-phase nano-silver-copper alloy solid solution solder paste, comprising single-phase nano-silver-copper alloy particles, a dispersant, a modifier, a diluent and a soldering flux, in terms of the mass percentage of the solder paste, the single-phase nano-silver Copper alloy particles account for 80% to 90%, dispersants account for 2% to 8%, modifiers account for 2% to 8%, thinners account for 2% to 8%, and fluxes account for 2% to 8%.

[0031] Preferably, the flux is rosin resin and its derivatives.

[0032] Preferably, the modifying agent is one or more combinations of polyethylene glycol, stearic acid, and fish oil.

[0033] Preferably, the dispersant is at least one of citric acid and polyvinylpyrrolidone, and the molecular weight of the polyvinylpyrrolidone is 30000-58000.

[0034] Preferably, the diluent is at least one of alcohol and acetone.

[0035] A method for preparing the above-mentioned micro-single-phase nano-silver-copper alloy solid solution sol...

Embodiment 1

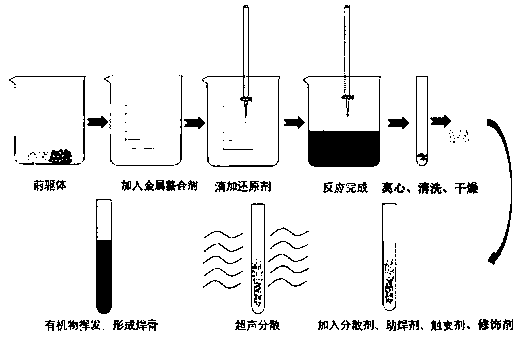

[0051] Such as figure 1 As shown, the specific method for preparing single-phase silver-copper nano-alloy particle solder paste with a silver-copper ratio of 1:1 in this example is as follows:

[0052] A single-phase nano-silver-copper alloy solid solution solder paste, comprising single-phase nano-silver-copper alloy particles, a dispersant, a modifier, a diluent and a soldering flux, in terms of the mass percentage of the solder paste, the single-phase nano-silver Copper alloy particles accounted for 84%, dispersants accounted for 3%, modifiers accounted for 7%, thinners accounted for 3%, and flux accounted for 3%.

[0053] A preparation method of the above-mentioned single-phase nano-silver-copper alloy solid solution solder paste, the specific steps are as follows:

[0054] Step 1: Incorporate AgNO 3 and CuCl 2 As a precursor, it is placed in a reaction vessel with a molar ratio of 1:1;

[0055] Step 2: adding deionized water into the reaction vessel as a solvent to co...

Embodiment 2

[0063] Such as figure 1 As shown, the specific method for preparing single-phase nano-silver-copper alloy particle solder paste with a silver-copper ratio of 3:1 in this example is as follows:

[0064] A single-phase nano-silver-copper alloy solid solution solder paste, comprising single-phase nano-silver-copper alloy particles, a dispersant, a modifier, a diluent and a soldering flux, in terms of the mass percentage of the solder paste, the single-phase nano-silver Copper alloy particles account for 80%, dispersant accounts for 5%, modifier accounts for 5%, thinner accounts for 5%, and flux accounts for 5%.

[0065] A preparation method of the above-mentioned single-phase nano-silver-copper alloy solid solution solder paste, the specific steps are as follows:

[0066] Step 1: Incorporate AgNO 3 and CuSO 4 As a precursor, it is placed in a reaction vessel with a molar ratio of 3:1;

[0067] Step 2: adding deionized water into the reaction vessel as a solvent to completely ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com