Dense shish-kebab super-strong and super wear-resistant polyethylene composite material and preparation method thereof

A composite material and polyethylene technology, applied in the field of composite materials, can solve the problems that the mechanical properties and friction resistance of HDPE-based materials cannot be achieved, the use of HDPE is limited, and the preparation process is complicated, so as to improve the interface bonding effect, reduce performance loss, Simple and easy-to-achieve effects of process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

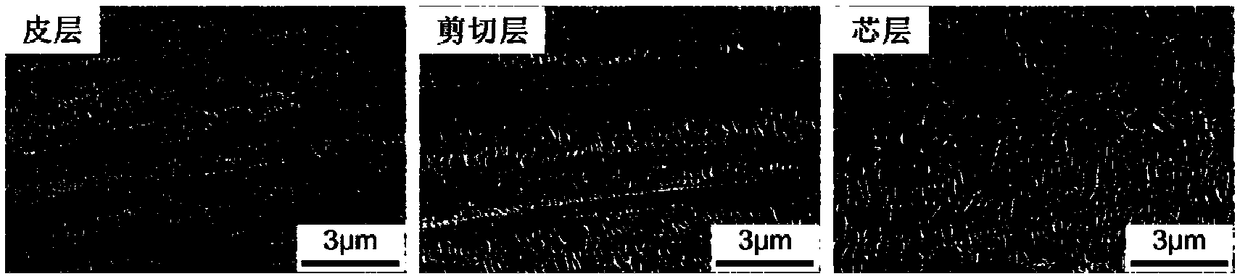

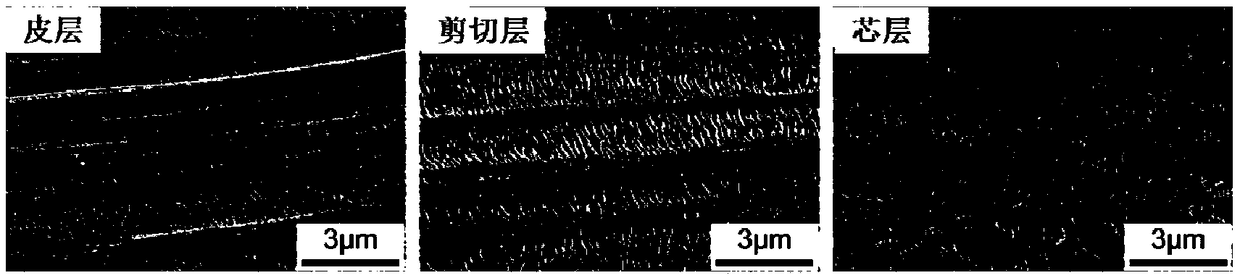

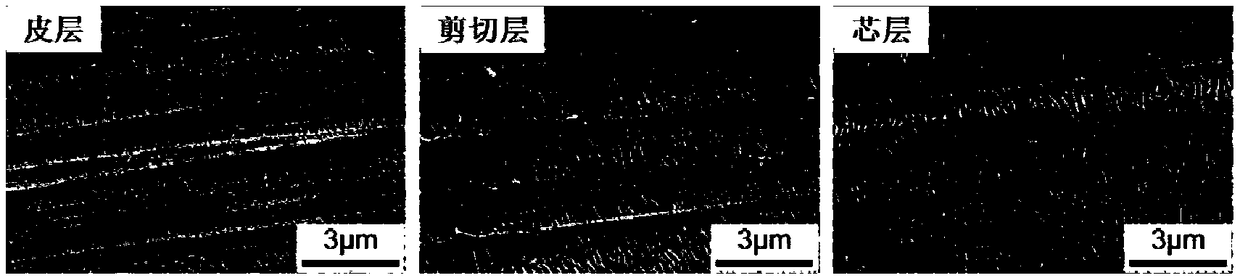

Image

Examples

Embodiment 1

[0026] A kind of preparation method of HDPE / UHMWPE composite material of the present embodiment, specific preparation steps are as follows:

[0027] (1) As a comparison, pure high-density polyethylene is dried at 75°C for 10 hours in a blast drying oven to remove residual moisture; the dried HDPE is extruded by means of a twin-screw extruder, and the conveying compression section of the extruder , The temperature of the melting section and the metering section is set to 120-200°C, 200-230°C, and 220-190°C in sequence, the screw speed is set to 100 rpm, and the feeding speed is 10 rpm. Traction by a granulator, granulation, and drying for later use;

[0028] (2) In the process of melt molding, the method of superimposed oscillation and push-pull composite force field is used for molding: the dried material obtained in (1) is molded by this method, and its main parameters are set to: screw The barrel temperature is set to 210°C, the plunger barrel temperature is set to 210°C, t...

Embodiment 2

[0030] A kind of preparation method of HDPE / UHMWPE composite material of the present embodiment, specific preparation steps are as follows:

[0031] (1) Preparation of HDPE / UHMWPE premix: First, dry high-density polyethylene and ultra-high molecular weight polyethylene in a blast drying oven at 75°C for 10 hours to remove residual moisture; then, dry the dried HDPE and UHMWPE According to the mass ratio of 95:5, a high-speed mixer was used to mix for 2 minutes at a speed of 10,000 rpm to obtain a premix;

[0032](2) Preparation of HDPE / UHMWPE blend: The premix is directly melted and blended by means of a twin-screw extruder. ~230°C, 220~190°C, the screw speed is set to 100 rpm, and the feeding speed is 10 rpm. Traction by a granulator, granulation, and drying for later use;

[0033] (3) In the melt molding process, the method of superimposing oscillation and push-pull composite force field is molded: the dried material obtained in (2) is molded by this method, and its main...

Embodiment 3

[0035] A kind of preparation method of HDPE / UHMWPE composite material of the present embodiment, specific preparation steps are as follows:

[0036] (1) Preparation of HDPE / UHMWPE premix: First, dry high-density polyethylene and ultra-high molecular weight polyethylene in a blast drying oven at 75°C for 10 hours to remove residual moisture; then, dry the dried HDPE and UHMWPE According to the mass ratio of 90:10, a high-speed mixer was used to mix for 2 minutes at a speed of 10,000 rpm to obtain a premix;

[0037] (2) Preparation of HDPE / UHMWPE blend: The premix is directly melted and blended by means of a twin-screw extruder. ~230°C, 220~190°C, the screw speed is set to 100 rpm, and the feeding speed is 10 rpm. Traction by a granulator, granulation, and drying for later use;

[0038] (3) In the melt molding process, the method of superimposing oscillation and push-pull composite force field is molded: the dried material obtained in (2) is molded by this method, and its ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Relative molecular mass | aaaaa | aaaaa |

| Relative molecular mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com