System and technology for producing chlorosulfonic acid from m/p-phthaloyl chloride tail gas

A technology for phthaloyl chloride tail gas and production system, which is applied in chlorosulfonic acid, inorganic chemistry, non-metallic elements, etc., can solve the problem that chlorosulfonic acid production equipment is easy to corrode, by-products are difficult to sell, and there is a long-term backlog, and the degree of raw material pretreatment is high. problems, to achieve the effect of reducing m/terephthaloyl chloride tail gas, solving the backlog of by-products, and reducing environmental risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

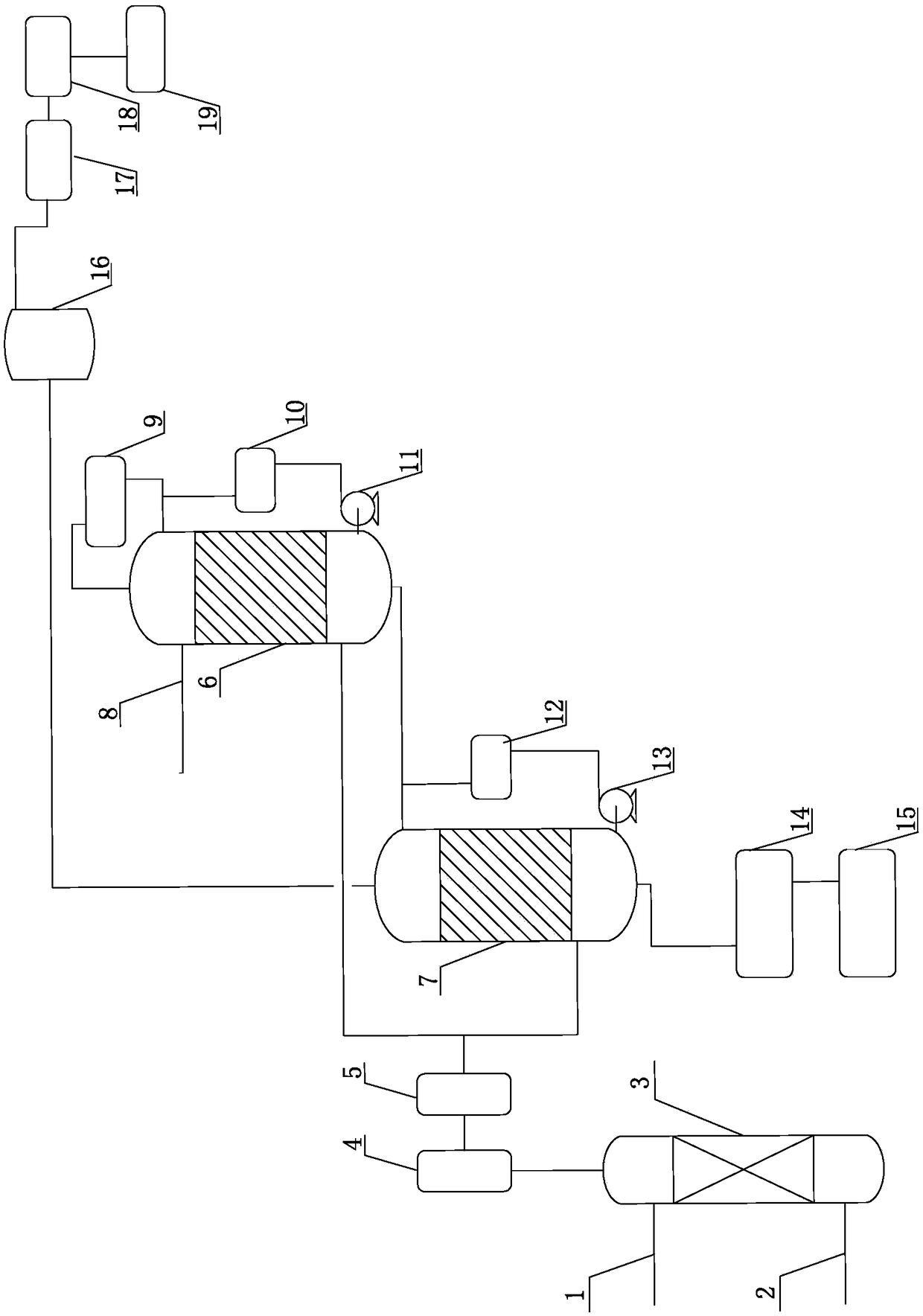

[0048] The system of producing chlorosulfonic acid from the m / terephthaloyl chloride tail gas described in present embodiment 1, with reference to the attached figure 1 , including tail gas pretreatment system, chlorosulfonic acid production system and sulfur dioxide treatment and recovery system. In the tail gas pretreatment system, the gas phase outlet at the top of the absorption tower 3 is connected to the lower part of the tail gas condenser 4, and the tube side of the tail gas condenser 4 is used. Divided into two ways.

[0049] Come out from mist catcher 5 and be divided into two roads, all the way enters primary reaction tower 6 from the bottom side of primary reaction tower 6, in primary reaction tower 6, enters the liquid sulfur trioxide of primary reaction tower 6 with the top Reaction, after the reaction gas phase is condensed by the circulating condenser 9, it is refluxed into the first-stage reaction tower 6, and the reaction liquid at the bottom of the first-st...

Embodiment 2

[0062] Compared with Example 1, this embodiment 2 differs only in that the temperature in the primary reaction tower 6 is maintained at 45±5°C, the outlet temperature of the primary condenser 10 is maintained at 35±5°C, and the temperature of the secondary reaction tower 7 is maintained at 45±5°C. kept at 58±8°C, the outlet temperature of secondary condenser 12 was kept at 55±10°C, SO 3 The conversion tank 16 is a sulfuric acid absorption tank, and the concentrated sulfuric acid with a content of 98% is added therein.

[0063] In terms of mass fraction, the tail gas of m / terephthaloyl dichloride consists of the following components: SO 2 63.5%, HCl 36%, acid chloride 0.5%.

[0064] Liquid SO 3 excess. Liquid SO 3 The volume ratio of iso / terephthaloyl chloride tail gas is 1:1500.

[0065] The air pressure at the top outlet of the first-stage reaction tower is 1-2KPa; the air pressure at the top outlet of the second-stage reaction tower is 2-4KPa.

[0066] The residence t...

Embodiment 3

[0069] Compared with Example 1, this embodiment 3 differs only in that the temperature in the primary reaction tower 6 is maintained at 55±5°C, the outlet temperature of the primary condenser 10 is maintained at 35±5°C, and the temperature of the secondary reaction tower 7 is maintained at 55±5°C. kept at 75±5°C, the outlet temperature of secondary condenser 12 was kept at 55±10°C, SO 3 The conversion tank 16 is a sulfuric acid absorption tank, and the concentrated sulfuric acid with a content of 98% is added therein.

[0070] In terms of mass fraction, the tail gas of m / terephthaloyl dichloride consists of the following components: SO 2 63.5%, HCl 36%, acid chloride 0.5%.

[0071] Liquid SO 3 excess. Liquid SO 3 The volume ratio of iso / terephthaloyl chloride tail gas is 1:1500.

[0072] The air pressure at the top outlet of the first-stage reaction tower is 1-2KPa; the air pressure at the top outlet of the second-stage reaction tower is 2-4KPa.

[0073] The residence t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com