Method for producing micron-sized bismuth manganate powder

A technology of high-grade bismuth manganate and its production method, which is applied in chemical instruments and methods, manganate/permanganate, manganese compounds, etc., and can solve the difficult large-scale industrial production of bismuth manganate, preparation equipment and operators High requirements, low yield and other problems, to achieve the effect of being suitable for large-scale industrial production, reducing the cost of tail gas treatment, and wide application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The invention proposes a preparation method of micron bismuth manganate powder, which comprises the following steps.

[0016] S1, put Bi 2 o 3 Soluble in HNO 3 solution, forming the first mixed solution under the condition of heating in a water bath.

[0017] S2. Add ammonia water to the first mixed solution to adjust the pH to form a precipitate, age, filter and clean the precipitate Bi(OH) 3 , followed by drying.

[0018] S3, the Bi(OH) 3 with MnCO 3 Put it into a roller ball mill with a molar ratio of 1:2, mix it evenly, and then calcine it. After cooling in the furnace, you can get micron-sized bismuth manganate powder.

[0019] In some embodiments of the present invention, the heating temperature of the water bath in S1 is 60-90°C.

[0020] In some embodiments of the invention, the HNO in S1 3 The molar concentration of the solution is 1-7 mol / L.

[0021] In some embodiments of the present invention, the concentration of ammonia water in S2 is 1-13 mol / L. ...

Embodiment 1

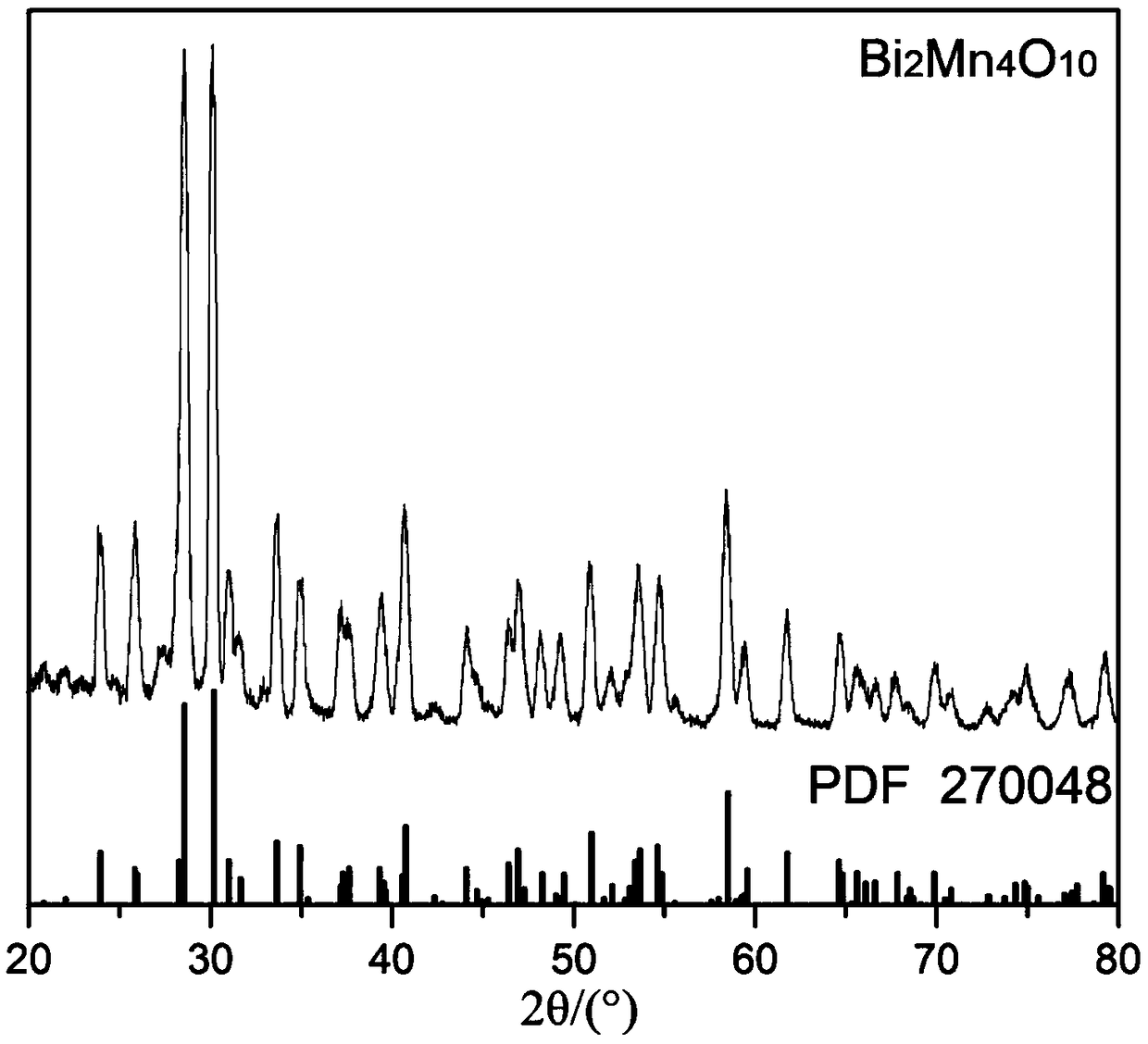

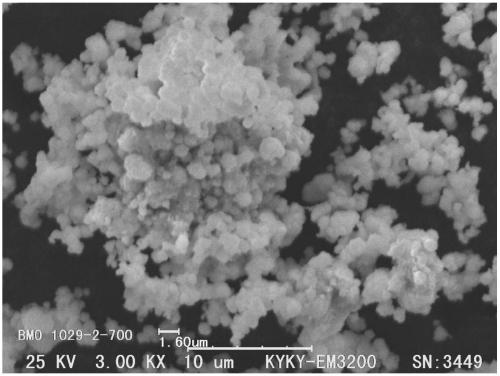

[0028] Weigh 46.6g Bi 2 o 3 Transfer to 100ml of HNO with a molar concentration of 7mol / L 3 In the solution, stir continuously in a water bath at 60°C until it is completely dissolved to form the first mixed solution; add 6mol / L ammonia water to the first mixed solution until the pH=9, age for 1h, and wait until the Bi in the solution is completely Precipitate as Bi(OH) 3 , filter Bi(OH) 3 Precipitated and washed 3 times with distilled water, dried at 80°C; by molar ratio Bi(OH) 3 : MnCO 3 =1:2 Weigh 46.1g MnCO 3 powder, the dried Bi(OH) 3 and MnCO 3 Put the powder into a roller ball mill to mix evenly, transfer to a muffle furnace for calcination at 700°C for 2 hours, and obtain a black powder after cooling in the furnace.

Embodiment 2

[0030] Weigh 46.6g Bi 2 o 3 Transfer to 80ml of HNO with a molar concentration of 7mol / L 3 In the solution, stir continuously in a water bath at 70°C until it is completely dissolved to form the first mixed solution; add 1mol / L ammonia water to the first mixed solution until the pH=9.5, and age for 2h until the Bi in the solution is completely Precipitate as Bi(OH) 3 , filter Bi(OH) 3 Precipitated and washed 3 times with distilled water, dried at 60°C; molar ratio Bi(OH) 3 : MnCO 3 =1:2 Weigh 46.1g MnCO 3 powder, the dried Bi(OH) 3 and MnCO 3 Put the powder into a roller ball mill to mix evenly, transfer to a muffle furnace for calcination at 500°C for 10 hours, and obtain a black powder after cooling in the furnace.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com