Application of glass-ceramic material

A glass-ceramic and micro-crystal technology, which is applied in the application field of glass-ceramic materials, can solve the problems of poor laser protection performance of glass materials, limited application scope, and difficulty in obtaining large inorganic single crystals, and achieves good optical limiting effect. , high chemical stability and thermal stability, excellent optical clipping ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

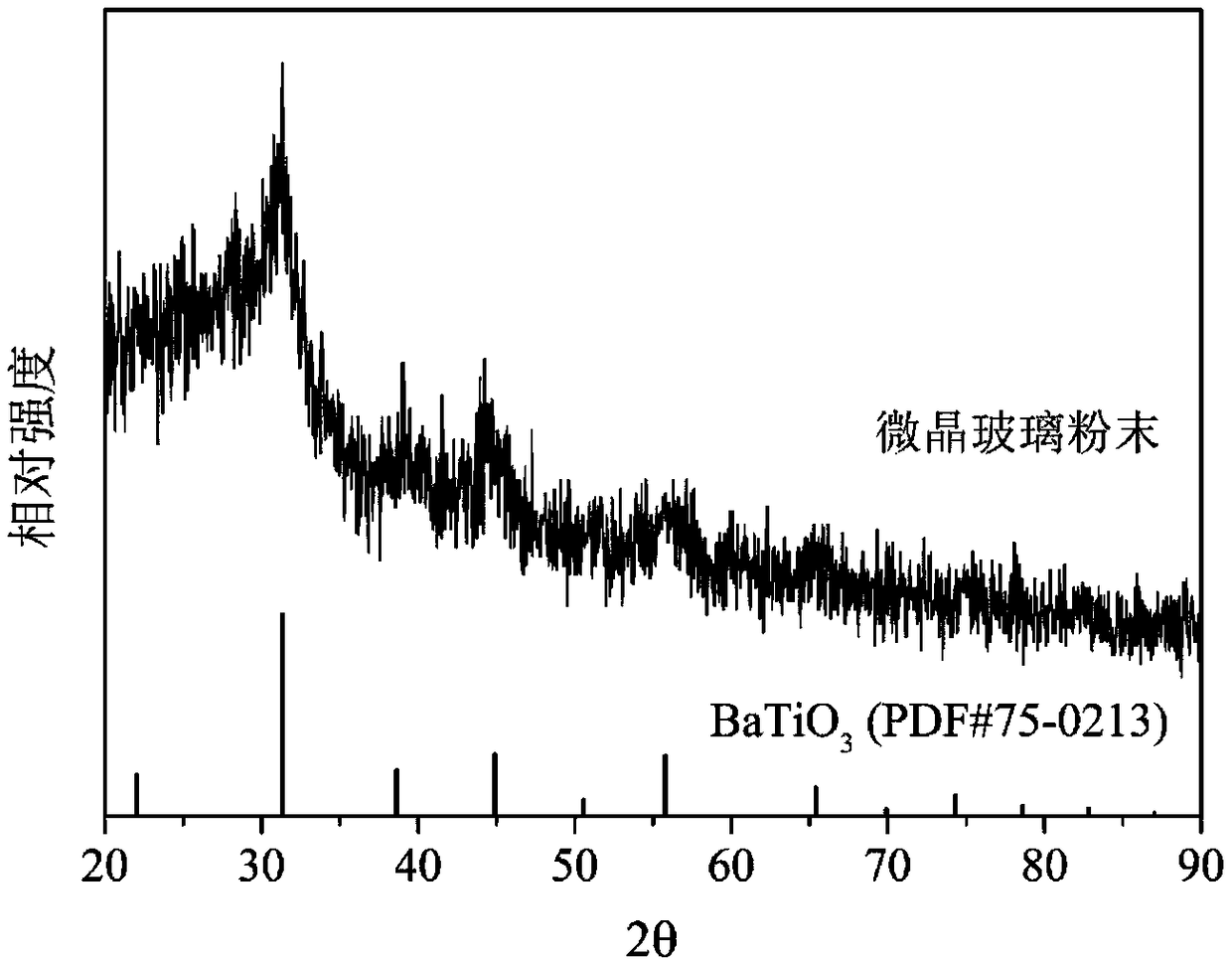

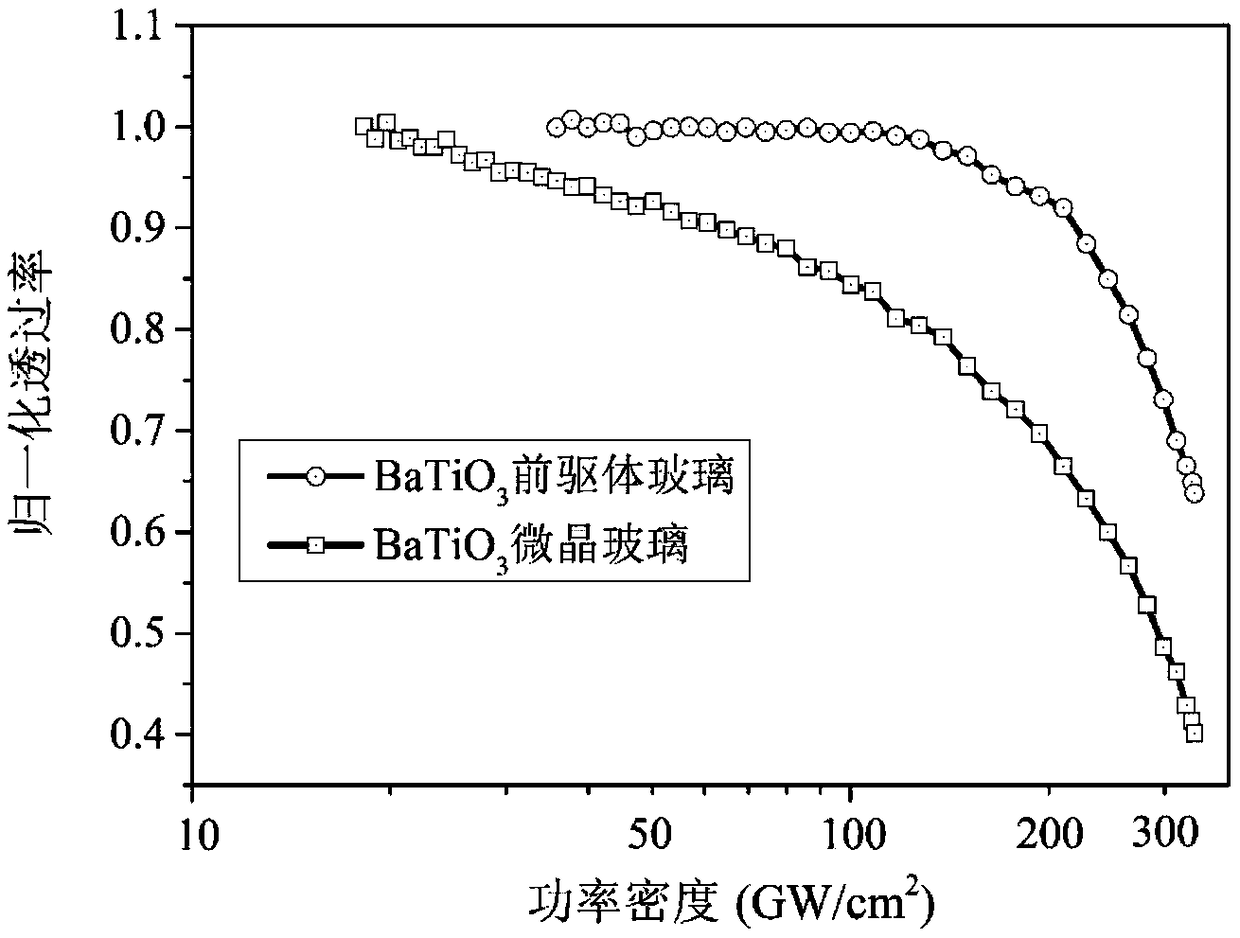

[0035] BaTiO 3 Optical limiting glass-ceramics

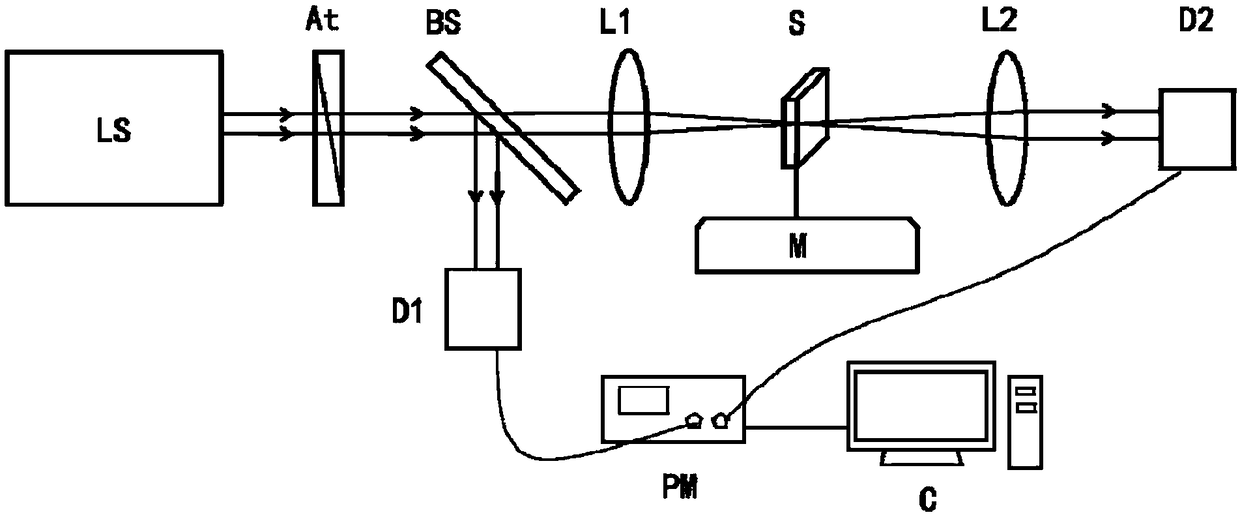

[0036] The BaTiO selected in this embodiment 3 Glass-ceramic, containing high polarizability Ti in glass matrix and crystallite phase 4+ , After heat treatment and crystallization, it has better optical limiting performance than the precursor glass. The optical limiting mechanism is two-photon absorption, and the optical limiting wavelength range is 400-800nm. The preparation of the glass-ceramic and the optical limiting performance of the 530nm-120fs-1kHz pulsed laser are described in detail below.

[0037] (1) BaTiO 3 Preparation of glass-ceramics

[0038] Select high-purity raw materials, and the molar ratio between raw materials is controlled at 19% Na 2 CO 3 , 24% BaCO 3 , 23%TiO 2 , 10% B 2 o 3 , 20% SiO2 2 , 4% Al 2 o 3 .

[0039] A total of 40 grams of raw materials were weighed, ground in an agate mortar for 40 minutes, then loaded into a platinum crucible, and placed in a furnace at 1400° C. for 1 hour. ...

Embodiment 2

[0045] LiNbO 3 Optical limiting glass-ceramics

[0046] The LiNbO selected in this embodiment 3 Glass-ceramics, the glass matrix contains Nb with high polarizability 5+ , After heat treatment and crystallization, it has better optical limiting performance than the precursor glass. The optical limiting mechanism is two-photon absorption, and the optical limiting wavelength range is 400-800nm. The preparation of the glass-ceramic and the optical limiting performance of the 530nm-120fs-1kHz pulsed laser are described in detail below.

[0047] (1) LiNbO 3 Preparation of glass-ceramics

[0048] Select high-purity raw materials, and control the molar ratio between raw materials to 35% Li 2 CO 3 , 25% Nb 2 o 5 , 40% SiO 2 .

[0049] A total of 40 grams of raw materials were weighed, ground in an agate mortar for 40 minutes, then put into a platinum crucible, and placed in a furnace at 1450° C. for 30 minutes. The melted glass is poured on a copper plate, then transferred t...

Embodiment 3

[0055] LiTaO 3 Optical limiting glass-ceramics

[0056] The LiTaO selected in this embodiment 3 Glass-ceramics, the glass matrix contains Ta with high polarizability 5+ , After thermal treatment and crystallization, it has better optical limiting performance than the precursor glass. The optical limiting mechanism is two-photon absorption, and the optical limiting wavelength range is 350-600nm. The preparation of the glass-ceramic and the optical limiting performance of the 450nm-120fs-1kHz pulsed laser are described in detail below.

[0057] (1)LiTaO 3 Preparation of glass-ceramics

[0058] Select high-purity raw materials, and the molar ratio between raw materials is controlled to 26% Li 2 CO 3 , 21% Ta 2 o 5 , 35% SiO 2 , 18%Al 2 o 3 .

[0059] A total of 40 grams of raw materials were weighed, ground in an agate mortar for 40 minutes, then put into a platinum crucible, and placed in a furnace at 1600° C. for 30 minutes. Pour the molten glass into two cylindric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com