Novel type environmentally-friendly converter mending material for converter with large scrap ratio and preparation method of converter mending material

A technology of scrap steel ratio and furnace repair charge, which is applied in the field of new large scrap steel ratio converter environmental protection furnace repair charge and its preparation, can solve the problem of unfavorable magnesia resources and the long-term development of green environmental protection concepts, the ineffective use of fused magnesia, and the low utilization rate and other problems, to achieve the effect of improving the efficiency of the converter operation, good spreading and uniformity, and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

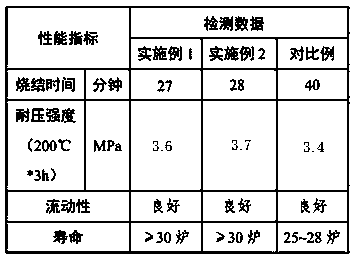

Examples

Embodiment 1

[0032] A new type of environmentally friendly refurbishment material for a converter with a large scrap steel ratio in this embodiment is applied to a converter lining mainly made of high-carbon steel. The furnace charge is made of waste magnesia carbon bricks and high-temperature modified pitch, the mass percentage of 50-100mm particles of waste magnesia carbon bricks (component A) is 70%, and the mass percentage of 5-20mm particles of waste magnesia carbon bricks (component B) 25% by mass, high temperature modified asphalt (component C) 5% by mass, made into a repair charge with 80% magnesium oxide (MgO) content and 20% carbon (C) content.

[0033] After the converter is tapped, the excess slag is poured out, and the amount of steel added is 18kg / t, put into the scrap steel hopper and added to the converter at one time. Properly shake the furnace back and forth, so that the furnace charge and slag are fully mixed and evenly distributed. Then shake the converter to an approp...

Embodiment 2

[0044] A new type of environmentally friendly refurbishment material for a converter with a large scrap steel ratio in this embodiment is applied to a converter lining mainly made of low-carbon steel. The repair material is made of waste magnesia-carbon bricks and high-temperature modified asphalt. The mass percentage of 50-100mm grain waste magnesia-carbon bricks accounts for 80%, and the mass percentage of 5-20mm grain waste magnesia-carbon bricks accounts for 10%. The mass percentage of pitch is 10%, and it is made into a repair charge with a magnesium oxide (MgO) content of 75% and a carbon (C) content of 25%.

[0045] After the converter is tapped, excess slag is poured out, and 22kg / t of steel is added, put into the scrap steel hopper and added to the converter at one time. Properly shake the furnace back and forth, so that the furnace charge and slag are fully mixed evenly. Then shake the converter to an appropriate angle, so that the repair material and slag stay in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com