Preparation method of ultraviolet absorbent UV-9

A technology of UV-9 and absorber, which is applied in the field of preparation of ultraviolet absorber UV-9, can solve the problems of high cost, uneven color, unfavorable for the next step, etc., and achieve the goal of reducing product cost and improving product yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

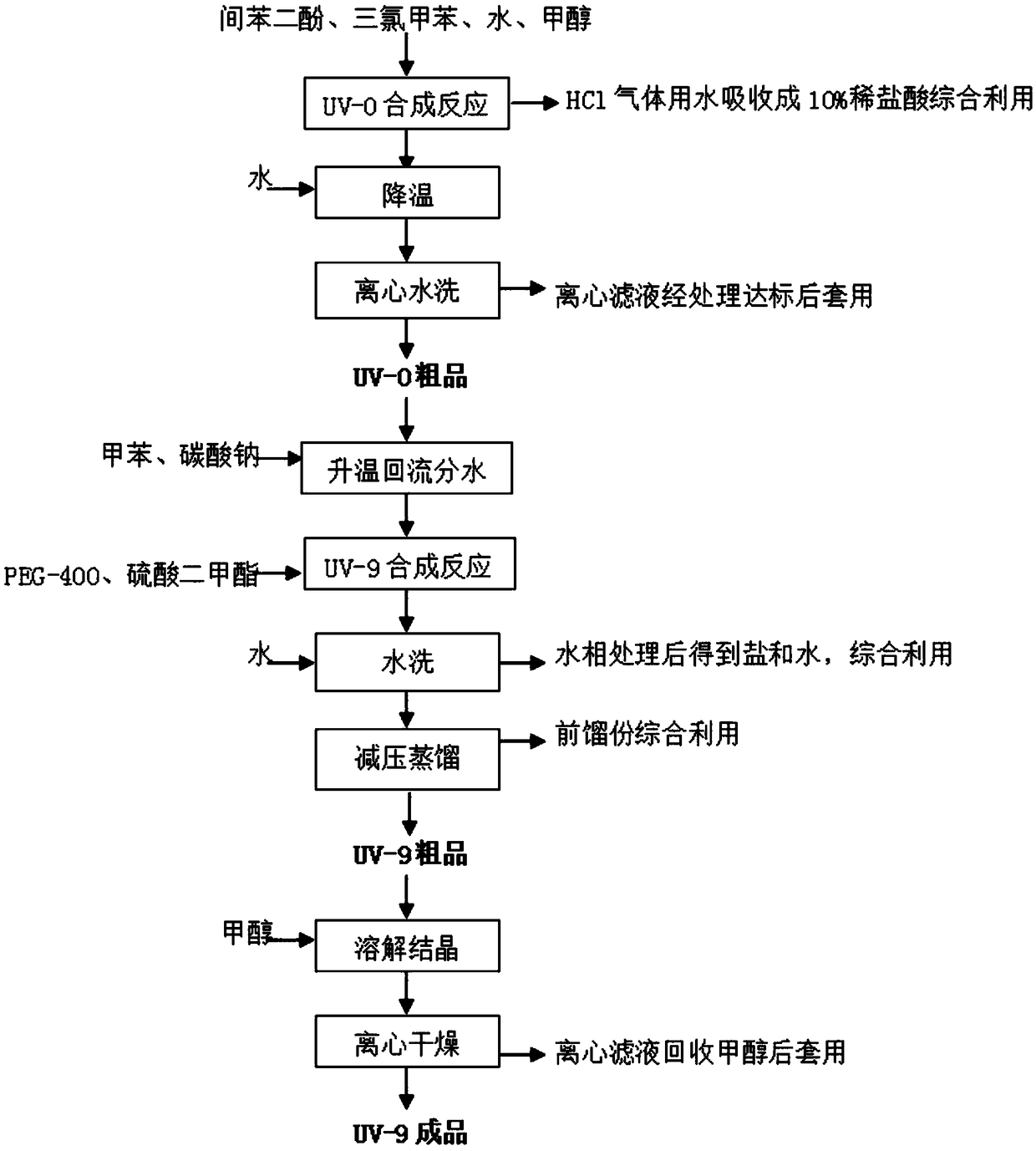

Method used

Image

Examples

Embodiment 1

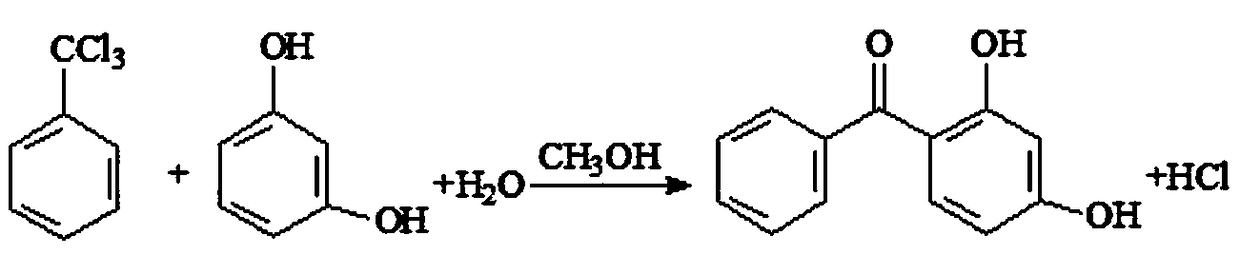

[0025] 1. Synthesis of the first step:

[0026]

[0027] When synthesizing UV-9, first add 550kg of water and 100kg of methanol into the UV-0 reactor, start stirring and add 240kg of resorcinol, raise the temperature to 55°C, keep it warm for 40min, and then add 460kg of trichlorotoluene dropwise to the UV-9 -0 reaction kettle, the dropwise addition time is about 6 hours, then control the temperature at 55-60°C, keep the temperature for 5-6 hours, and take samples to check whether the reaction has reached the end point. After the reaction, the mother liquor was dried by centrifugation, and washed with water until neutral to obtain 470 kg of 2,4-dihydroxybenzophenone, namely UV-0 crude product.

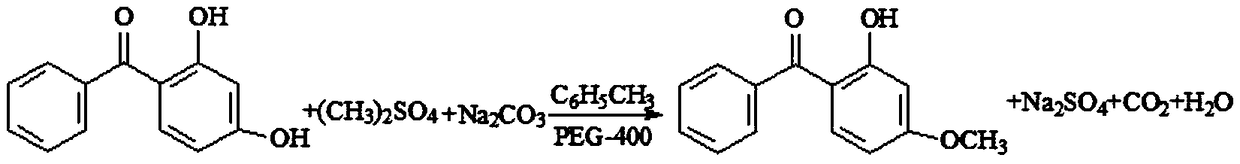

[0028] 2. Synthesis of the second step:

[0029]

[0030] Then add 100kg of toluene, 470kg of UV-0 crude product obtained above, and 200kg of acid-binding agent sodium carbonate into the UV-9 reaction kettle, heat up and reflux to separate water until no water drops appear, cool...

Embodiment 2

[0032] 1. Synthesis of the first step:

[0033]

[0034] When synthesizing UV-9, first add 500kg of water and 100kg of methanol into the UV-0 reactor, start stirring and add 165kg of resorcinol, raise the temperature to 55°C, keep it warm for 40min, and then add 391kg of trichlorotoluene dropwise to the UV-9 -0 reaction kettle, the dropwise addition time is about 6 hours, then control the temperature at 55-60°C, keep the temperature for 5-6 hours, and take samples to check whether the reaction has reached the end point. After the reaction, the mother liquor was dried by centrifugation, and washed with water until neutral to obtain 321 kg of 2,4-dihydroxybenzophenone, namely UV-0 crude product.

[0035] 2. Synthesis of the second step:

[0036]

[0037] Then add 100kg of toluene, 321kg of UV-0 crude product obtained above, and 200kg of acid-binding agent sodium carbonate into the UV-9 reaction kettle, heat up and reflux to separate water until no water drops appear, cool...

Embodiment 3

[0039] 1. Synthesis of the first step:

[0040]

[0041]When synthesizing UV-9, first add 600kg of water and 150kg of methanol into the UV-0 reactor, start stirring and add 275kg of resorcinol, heat up to 55°C, keep warm for 40min, and then add 586kg of trichlorotoluene dropwise to the UV-9 -0 reaction kettle, the dropwise addition time is about 6 hours, then control the temperature at 55-60°C, keep the temperature for 5-6 hours, and take samples to check whether the reaction has reached the end point. After the reaction, the mother liquor was dried by centrifugation, and washed with water until neutral to obtain 535 kg of 2,4-dihydroxybenzophenone, namely UV-0 crude product.

[0042] 2. Synthesis of the second step:

[0043]

[0044] Then add 100kg of toluene, 535kg of UV-0 crude product obtained above, and 200kg of acid-binding agent sodium carbonate into the UV-9 reaction kettle, heat up and reflux to separate water until no water drops appear, cool down to 40°C, add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com