Special heat vulcanization adhesive for shock insulating high damping rubber

A thermal vulcanization and adhesive technology, applied in the direction of adhesives, non-polymer organic compound adhesives, non-polymer adhesive additives, etc., can solve the problems of weakening the force of metal skeleton and low bonding strength of metal skeleton, and achieve improvement Tiling and laying, improved impact resistance, improved bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The pigments and fillers in the present invention are inert pigments and fillers, which are components for coloring and filling the vulcanized and cured glue. It can be organic pigment or inorganic salt filler, such as carbon black, lithopone, iron oxide, graphite, ultramarine blue, lead chrome yellow, quinacridone purple, anthraquinone red, aluminum powder, copper powder, pearl powder, calcium carbonate , barium sulfate, silicon dioxide, talcum powder, bentonite, etc.; preferably, the inert pigments and fillers are carbon black and / or graphite powder; more preferably, the graphite powder is modified graphite powder; further preferably, the The preparation method of described modified graphite powder comprises the steps:

[0036] S1: Take 3g of graphite powder and add it to the reaction kettle, add 5g of concentrated nitric acid, stir at 50°C for 1 hour, cool to room temperature, wash with deionized water, and dry to obtain acid-treated graphite;

[0037] S2: Add 2 g o...

Embodiment 1

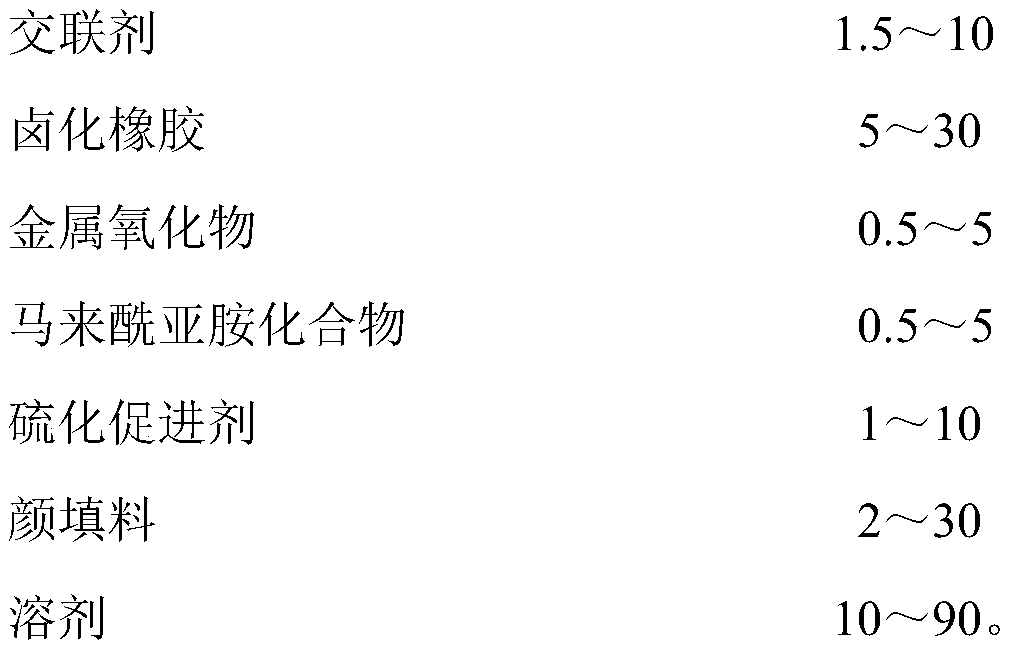

[0043] Embodiment 1 provides a kind of thermal vulcanization adhesive, the preparation raw material of described thermal vulcanization adhesive, by weight, comprises:

[0044]

[0045]

[0046] The crosslinking agent is N,N'-dinitroso-p-phenylene dihydroxy disodium; the halogenated rubber is chlorinated natural rubber; the metal oxide is aluminum oxide; The amine compound is N,N'-m-phenylene bismaleimide; the vulcanization accelerator is ethoxylated trimethylolpropane triacrylate; the pigment and filler is graphite powder; the solvent is di toluene.

Embodiment 2

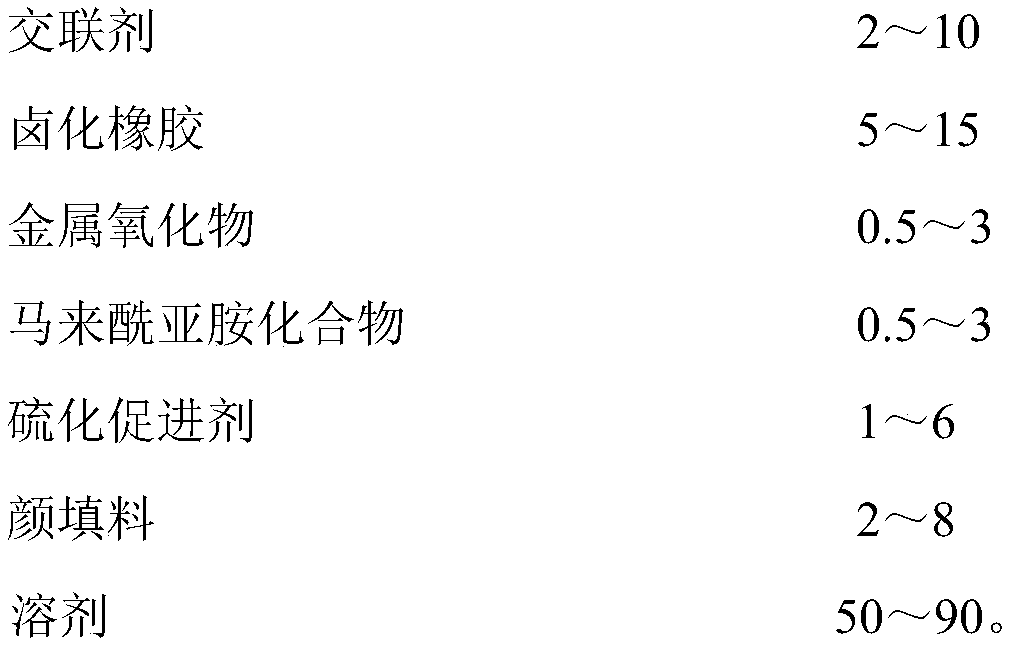

[0048] Embodiment 2 provides a kind of thermal vulcanization adhesive, the preparation raw material of described thermal vulcanization adhesive, by weight, comprises:

[0049]

[0050] The crosslinking agent is N,N'-dinitroso-p-phenylene dihydroxy disodium; the halogenated rubber is chlorinated natural rubber; the metal oxide is aluminum oxide; The amine compound is N,N'-m-phenylene bismaleimide; the vulcanization accelerator is ethoxylated trimethylolpropane triacrylate; the pigment and filler is graphite powder; the solvent is di toluene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com