Preparation method of waterproof paper fast food box

A fast food box and paper-based technology, which is applied in paper, papermaking, packaging paper, etc., can solve the problems of poor waterproof effect and high melting point, and achieve the effects of improving smoothness, high tensile strength, and improving viscosity stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

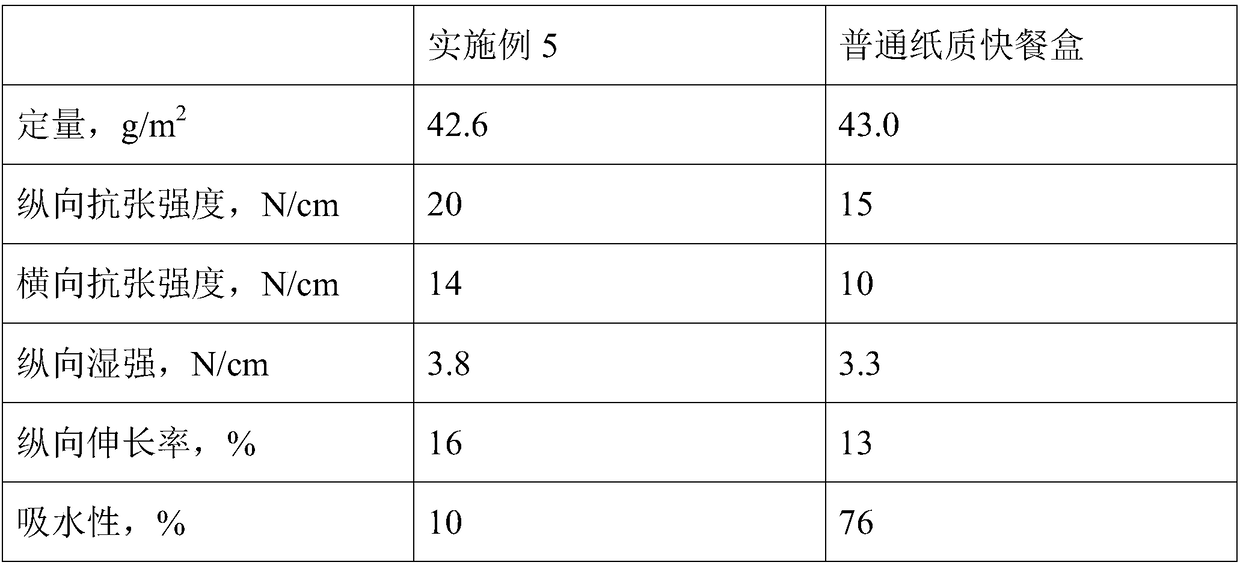

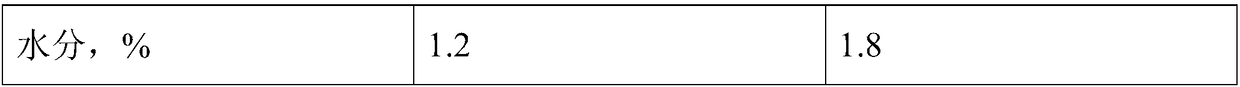

Examples

Embodiment 1

[0018] A preparation method of a waterproof paper snack box, comprising the steps of:

[0019] S1. Stir 4kg of carrageenan and 40kg of absolute ethanol for 15min at a stirring temperature of 80°C, add 0.2kg of a 46wt% hydrogen peroxide solution and stir for 20min, and use a 24wt% sodium hydroxide solution to adjust the pH of the system to 8.2-8.8. Insulate for 5 hours, lower to room temperature, use hydrochloric acid to adjust the pH of the system to neutral, add 8 kg of styrene and stir for 1 hour under the protection of nitrogen, the stirring temperature is 98 ° C, add 0.02 kg of dibenzoyl peroxide and stir for 4 hours, cool down, filter, wash , drying to obtain material a;

[0020] S2, 120kg Chinese fir pulp, 40kg mulberry pulp, and 24kg beech pulp are disintegrated with a pulper, and the grinding disc is beaten to a slurry with a concentration of 6.5wt% and a beating degree of 25°SR, adding 3kg hydroxyethyl cellulose, 1kg Xanthan gum and 1 kg of alginic acid were stirred ...

Embodiment 2

[0023] A preparation method of a waterproof paper snack box, comprising the steps of:

[0024] S1. Stir 12kg of carrageenan and 30kg of absolute ethanol for 24min at a stirring temperature of 72°C, add 1kg of a 42wt% hydrogen peroxide solution and stir for 40min, use a 15wt% sodium hydroxide solution to adjust the pH of the system to 8.2-8.8, and keep warm 10h, lower to room temperature, use hydrochloric acid to adjust the pH of the system to neutral, add 2kg of styrene and stir for 2h under the protection of nitrogen, the stirring temperature is 92°C, add 0.06kg of dibenzoyl peroxide and stir for 1h, cool down, filter, wash, Dry to obtain material a;

[0025] S2, 160kg fir pulp, 30kg mulberry pulp, and 35kg beech pulp are disintegrated by a pulper, and the grinding disc is beaten to a slurry with a concentration of 4.5wt% and a beating degree of 30°SR, adding 1kg hydroxyethyl cellulose, 2kg Xanthan gum and 0.4kg alginic acid were stirred for 10min at a stirring speed of 120r...

Embodiment 3

[0028] A preparation method of a waterproof paper snack box, comprising the steps of:

[0029] S1. Stir 6kg of carrageenan and 37kg of absolute ethanol for 18min at a stirring temperature of 78°C, add 0.4kg of 45wt% hydrogen peroxide solution and stir for 25min, and use a 22wt% sodium hydroxide solution to adjust the pH of the system to 8.2-8.8. Insulate for 6 hours, lower to room temperature, use hydrochloric acid to adjust the pH of the system to neutral, add 6 kg of styrene and stir for 1.2 hours under nitrogen protection, the stirring temperature is 96 ° C, add 0.03 kg of dibenzoyl peroxide and stir for 3 hours, cool down, filter, washing and drying to obtain material a;

[0030] S2, 130kg fir pulp, 37kg mulberry pulp, and 28kg beech pulp are disintegrated by a pulper, and the grinding disc is beaten to a slurry with a concentration of 6wt% and a beating degree of 26°SR, adding 2.5kg hydroxyethyl cellulose, 1.2 kg xanthan gum and 0.8 kg alginic acid were stirred for 6 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com