Cathode material for lithium ion battery, preparation method of cathode material and lithium ion battery

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve problems such as unfavorable mass production and processing, large fluctuations in product performance, poor product consistency, etc., to achieve reformation optimization, reversible The effect of increasing capacity and improving environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A method for preparing negative electrode materials for lithium ion batteries, comprising:

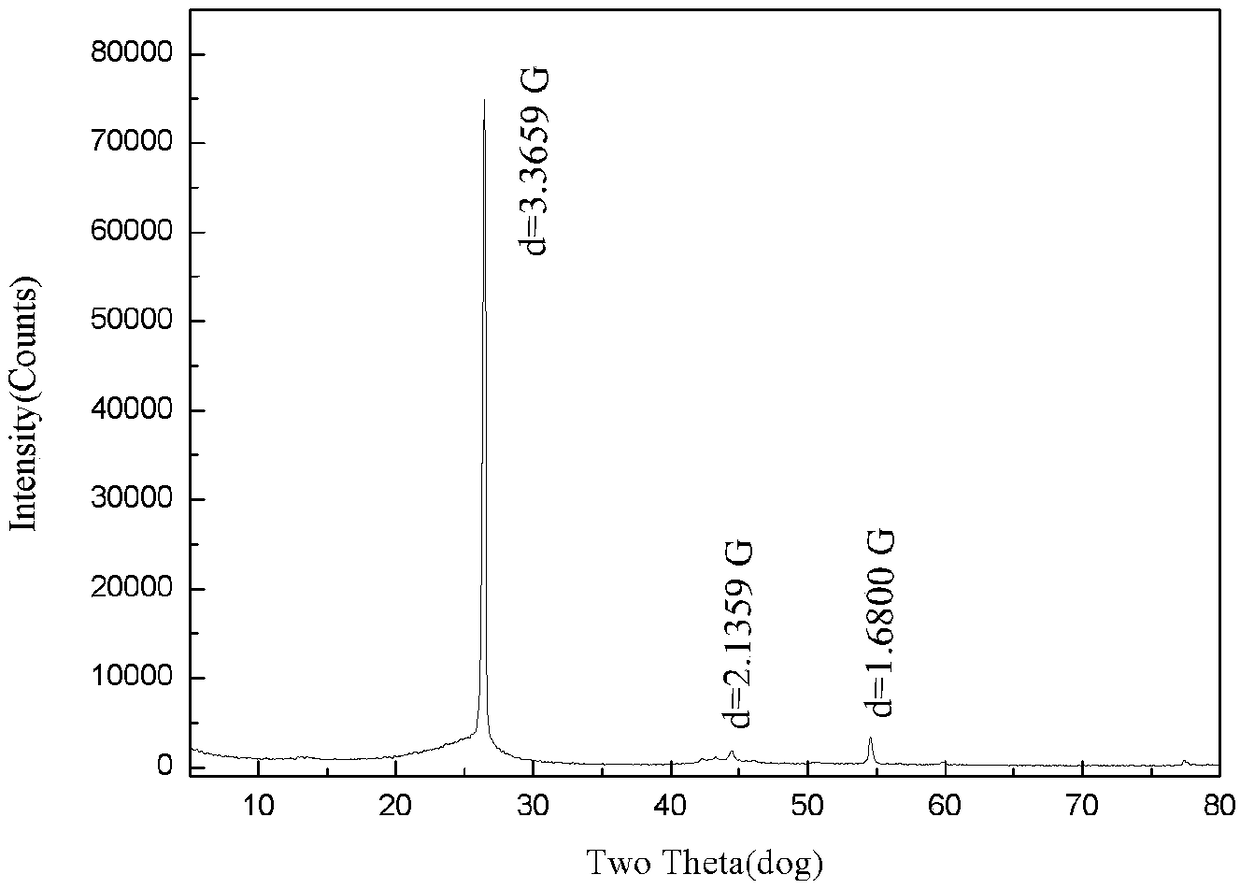

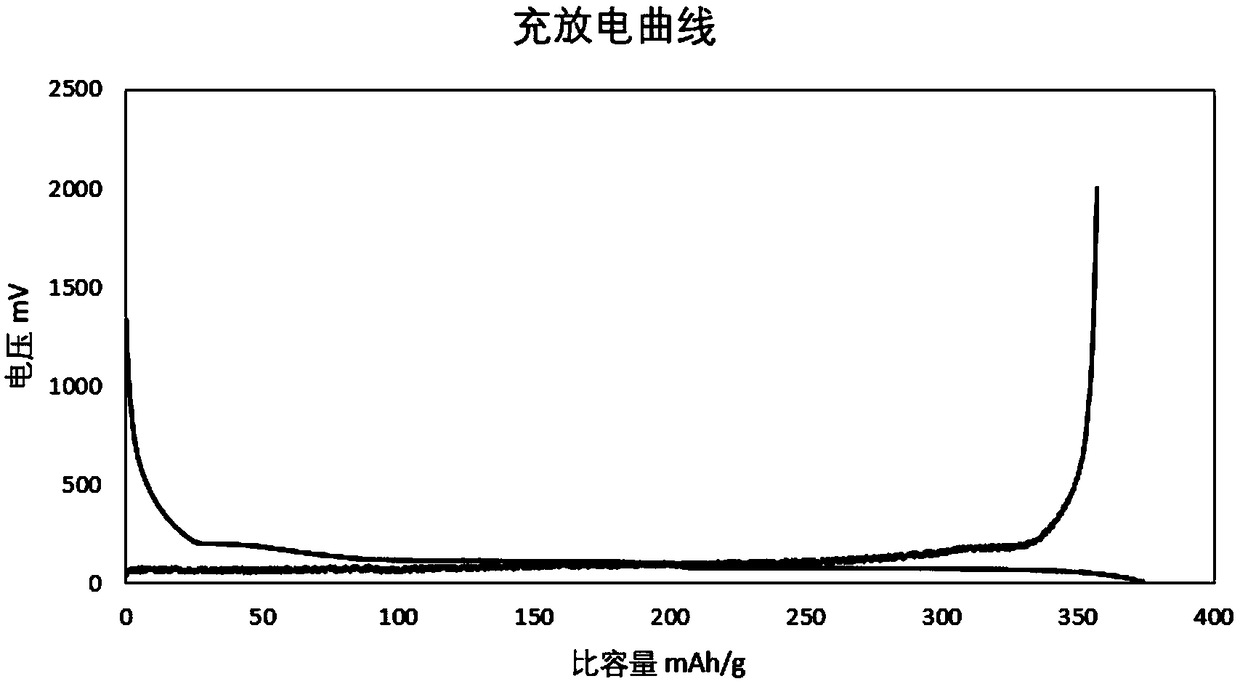

[0036] Put the raw ore coarse particles with a microcrystalline graphite content of 65-85% in a ball mill, and after ball milling at 300-500r / min for 5-7h, perform flotation, drying, and magnetic separation to obtain a D50 of 5-100um and a carbon content of In more than 90% of the microcrystalline graphite powder, put the microcrystalline graphite powder into the mixed acid solution with a volume ratio of hydrofluoric acid:hydrochloric acid=7-9:1-3, heat at 45-75°C, and stir for 2.5-3.5h , suction filtration, washing the filtrate with water until the pH of the eluting liquid is greater than 4, filtering and drying the filtrate to obtain a precursor a with a fixed carbon content greater than 95%; the precursor a is a microcrystal with low carbon and high acidity Graphite powder, the existing precursor a is generally high-carbon neutral microcrystalline graphite powder, but it tak...

specific Embodiment 1

[0037] A preparation method for a negative electrode material for a lithium ion battery, comprising:

[0038]The raw ore coarse particles with a microcrystalline graphite content of 75% are placed in a ball mill, and after ball milling at 400r / min for 6 hours, flotation, drying, and magnetic separation are performed to obtain microcrystalline graphite with a D50 of 5-100um and a carbon content of more than 90%. Crystalline graphite powder, put the microcrystalline graphite powder into the mixed acid solution with a volume ratio of hydrofluoric acid: hydrochloric acid = 8:2, heat at 65°C, stir for 3 hours, filter with suction, wash the filtrate with water until the pH of the washed liquid greater than 4, the filtrate is filtered and dried to obtain a precursor a with a fixed carbon content greater than 95%; the precursor a, binder, catalyst and auxiliary agent are placed in the In the ball mill, the binder is coal tar pitch, the catalyst is silicon carbide, the particle size D5...

specific Embodiment 2

[0039] A preparation method for a negative electrode material for a lithium ion battery, comprising:

[0040] The raw ore coarse particles with a microcrystalline graphite content of 68% are placed in a ball mill, and after ball milling at 450r / min for 7 hours, flotation, drying, and magnetic separation are performed to obtain microcrystalline graphite with a D50 of 5-100um and a carbon content of more than 90%. Crystalline graphite powder, put the microcrystalline graphite powder into the mixed acid solution with a volume ratio of hydrofluoric acid: hydrochloric acid = 8:2, heat at 65°C, stir for 3 hours, filter with suction, wash the filtrate with water until the pH of the washed liquid is greater than 4, the filtrate is filtered and dried to obtain a precursor a with a fixed carbon content greater than 95%; the precursor a, binder, catalyst and auxiliary agent are placed in a mass ratio of 80:30:10:8 In the ball mill, the binder is coal tar pitch, the catalyst is silicon ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com