Portable impedance self-adaption laser diode driving module

A technology of laser diodes and drive modules, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of laser diode damage, no over-current power-off and over-temperature power-off protection functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 Overall structure of the present invention

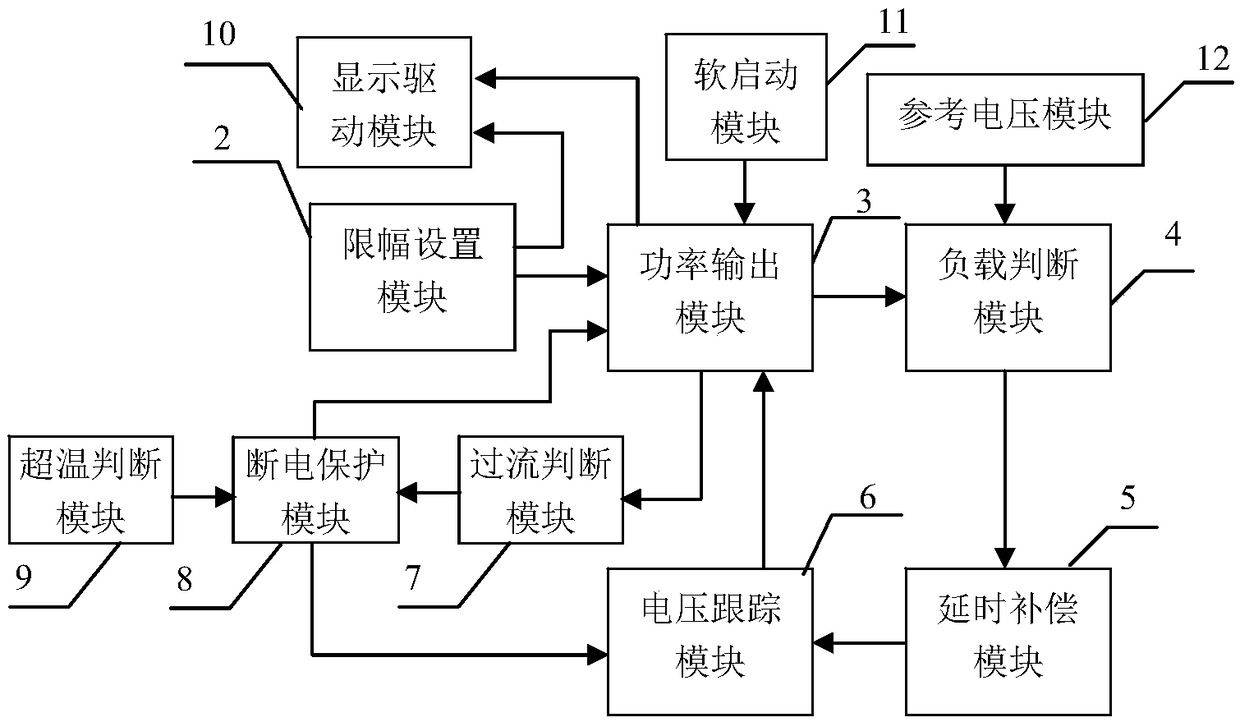

[0046] Overall structure of the present invention is as figure 1As shown, the structure includes front panel 1, limiter setting module 2, power output module 3, load judging module 4, delay compensation module 5, voltage tracking module 6, overcurrent judging module 7, power-off protection module 8, over-temperature Judgment module 9, display driver module 10, soft start module 11, reference voltage module 12, power management module 13; wherein, limiter setting module 2 is connected with power output module 3 and display driver module 10 respectively, soft start module 11 is connected with power output The modules 3 are connected, the power output module 3 is respectively connected to the display driver module 10, the load judgment module 4, and the overcurrent judgment module 7, the reference voltage module 12 is connected to the load judgment module 4, and the load judgment module 4 is connected to the delay c...

Embodiment 2

[0047] Embodiment 2 Front panel of the present invention

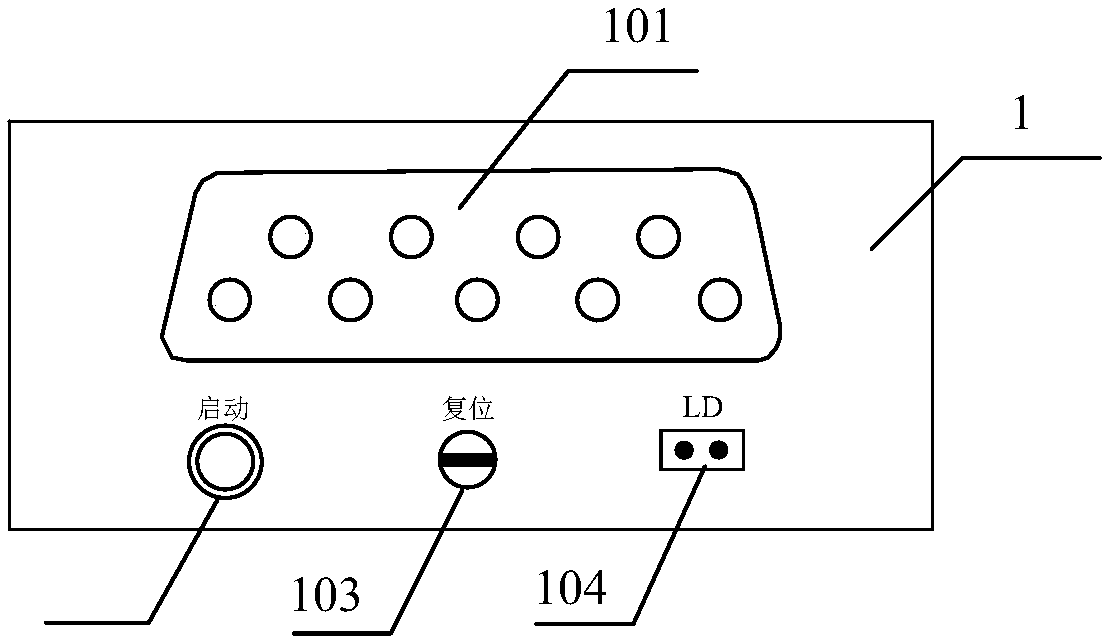

[0048] Front panel structure of the present invention such as image 3 As shown, it includes a 9-pin D-shaped interface 101, a start switch 102, a reset button 103, and a current output interface 104; the positive and negative terminals of the current output interface 104 are respectively connected to the ports PWR-out3 and PWR-out4 of the power output module 3 1 pin of the 9-pin D-shaped interface 101 is grounded, 6 pins are connected to the power supply Vcc / 2, 2 pins are connected to the power supply Vcc, 7 pins are connected to the power supply Vdd, and 3 pins and 8 pins are connected to the overtemperature judgment module 9 respectively. Port NTC1 and port NTC2, pin 4 is connected to port DIS-out in display driver module 10, pin 9 and pin 5 are connected to port L_set and port I_set in limiter setting module 2 respectively.

[0049] Among them, the 9-pin D-shaped interface 101 facilitates the integrated connection...

Embodiment 3

[0050] Embodiment 3 Limit setting module of the present invention

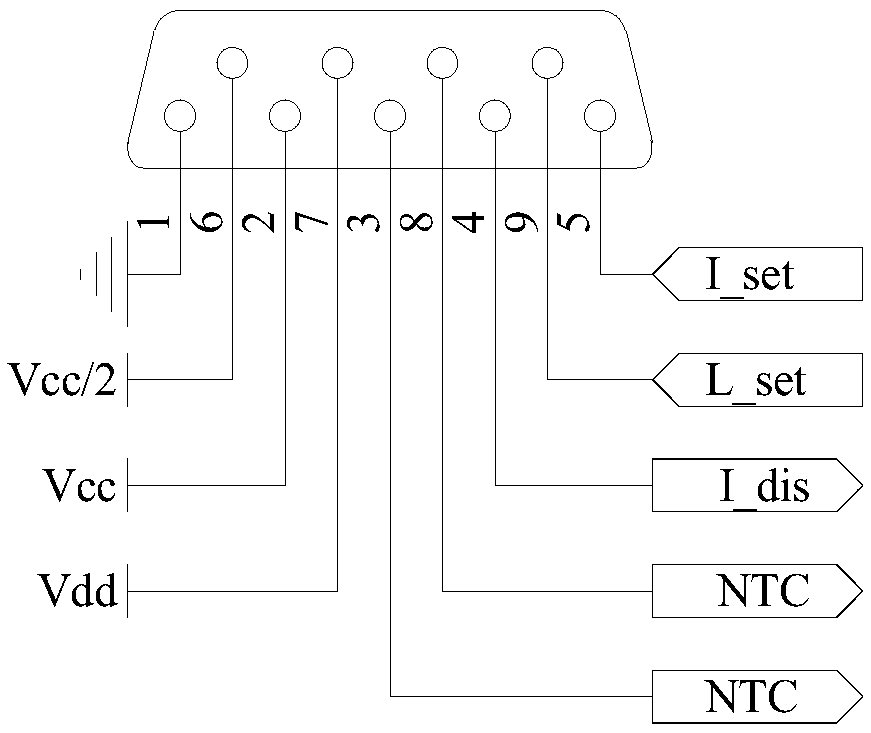

[0051] The principle circuit of limiter setting module 2 of the present invention is as Figure 4 As shown, one end of the resistor R42 is used as an input end of the limiter setting module 2, which is recorded as the port I_set, connected to pin 5 of the 9-pin D-shaped interface 101 on the front panel 1, and the other end of the resistor R42 is connected to the non-inverting input of the operational amplifier U11B terminal and the positive pole of diode D3, the negative pole of diode D3 is connected to the output terminal of operational amplifier U11A and one end of resistor R41, the other end of resistor R41 is connected to the inverting input terminal of operational amplifier U11A, the non-inverting input terminal of operational amplifier U11A is connected to one end of resistor R40 The other end of the resistor R40 is used as the other input end of the limiter setting module 2, which is recorded as the por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com