Phosphorus niobium oxide preparation method

A niobium oxide and oxide technology, applied in niobium compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of complex preparation process, environmental pollution, long reaction period and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

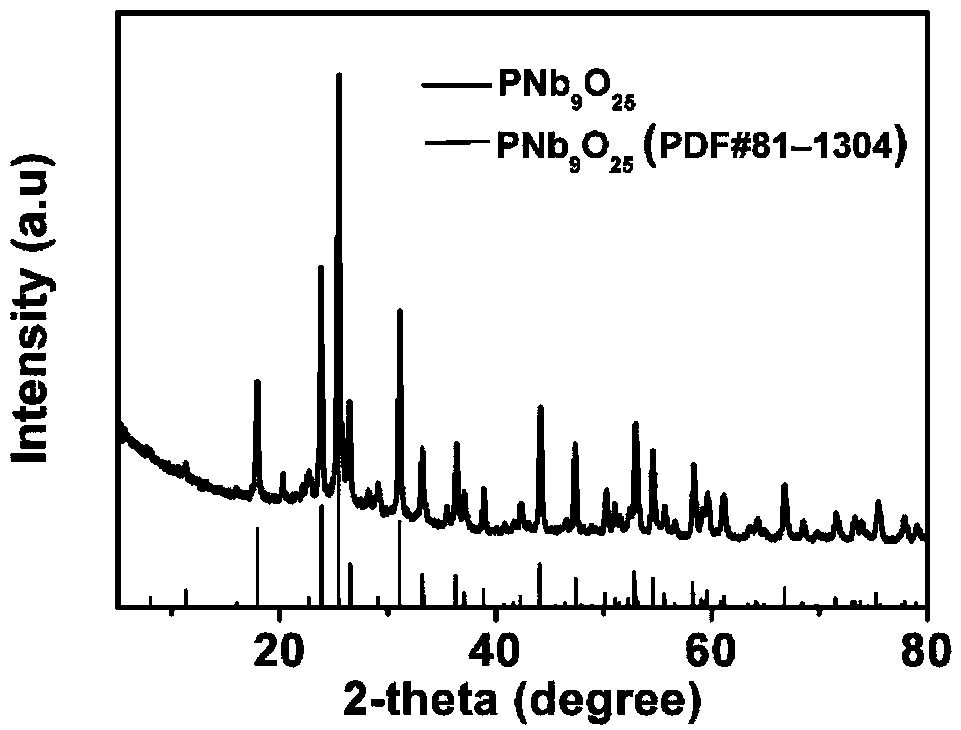

[0021] The present invention provides a method for preparing phosphorus niobium oxide, which includes the following steps:

[0022] Dissolving niobium pentachloride in an alcohol solvent, and performing a reduction reaction under airtight conditions to obtain a niobium oxide precursor;

[0023] Place the red phosphorus and the niobium oxide precursors in the upstream and downstream regions of the flowing protective atmosphere respectively; heat the upstream region to the temperature of the first region for 1-10 hours, and then heat the downstream region to the temperature of the second region , The compound reaction is carried out to obtain phosphorus niobium oxide; the temperature in the first zone is 425-550°C, and the temperature in the second zone is 650-950°C.

[0024] In the present invention, niobium pentachloride is dissolved in an alcohol solvent, and a reduction reaction is performed under a closed condition to obtain a niobium oxide precursor. The invention utilizes the r...

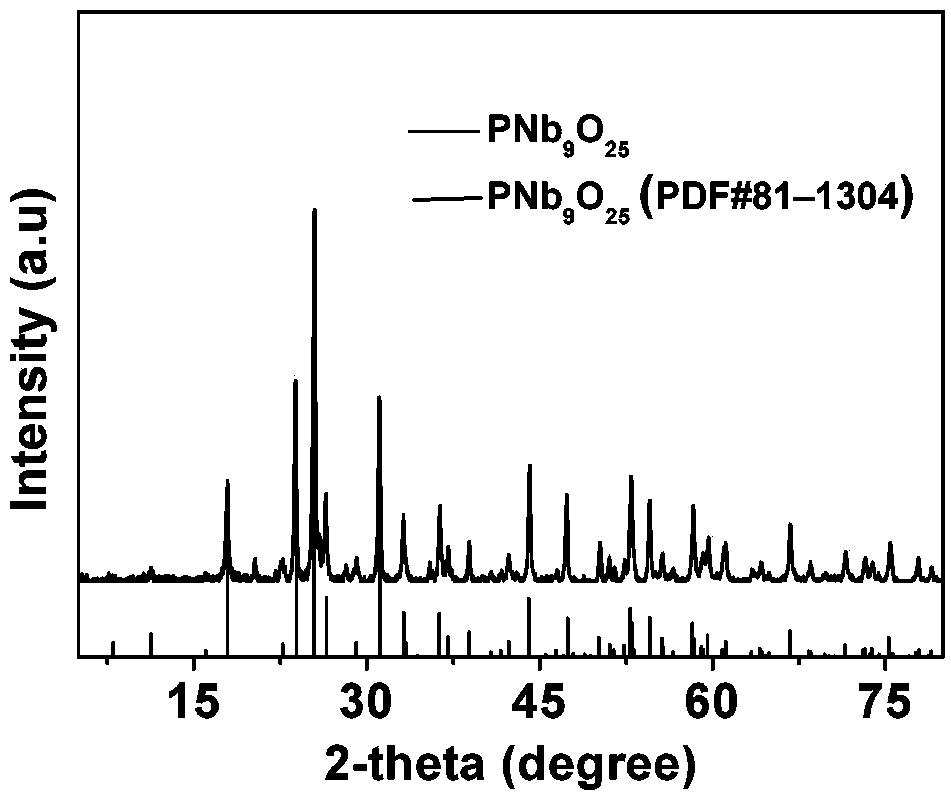

Embodiment 1

[0048] The niobium pentachloride powder was added to ethylene glycol and stirred at room temperature for 0.5 hours to obtain a solution with a concentration of 2 mol / L. Then the solution was charged into a polytetrafluoroethylene reactor. React at ℃ for 24 hours; after the reaction is complete, filter the mixture obtained from the reaction, and then wash the filtered solids with distilled water and absolute ethanol three times respectively, and then dry the washed solids at 70°C and grind to obtain Niobium oxide precursor with an average particle size of 5nm;

[0049] Put the niobium oxide precursor and red phosphorus into a ceramic crucible at a mass ratio of 1:3, and place them in the downstream and upstream of the vacuum atmosphere tube furnace. The distance between the niobium oxide precursor and the red phosphorus is 50cm, in an inert gas atmosphere (argon), heat the upstream area to 450°C at a rate of 2°C / min and keep it for 3 hours; then in an inert gas atmosphere (argon) ...

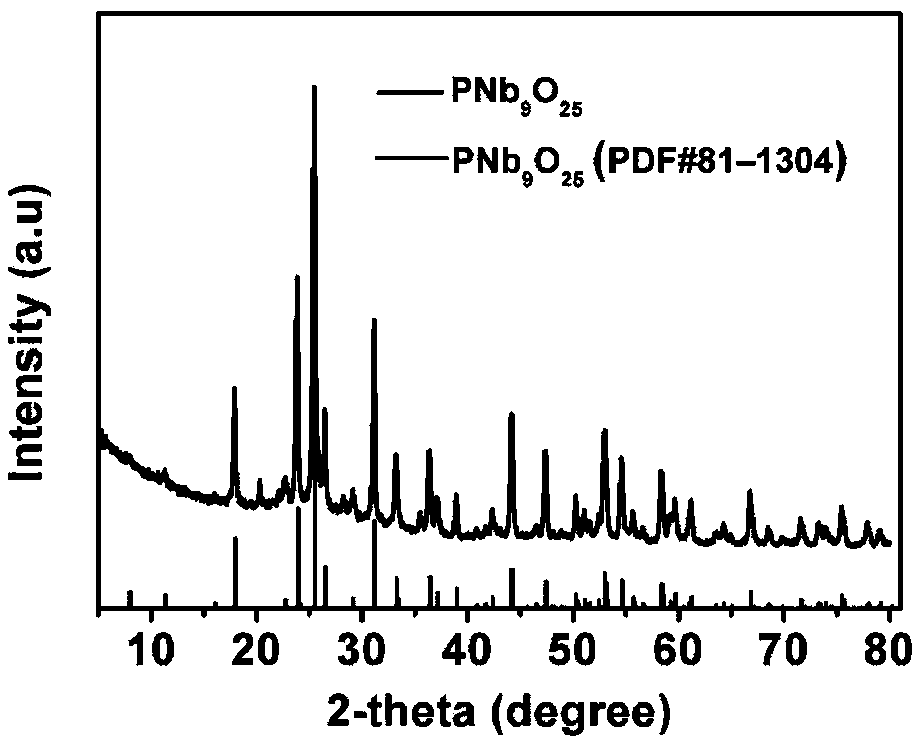

Embodiment 2

[0051] The niobium pentachloride powder was added to ethylene glycol and stirred at room temperature for 0.5 hours to obtain a solution with a concentration of 1.5 mol / L. Then the solution was put into a polytetrafluoroethylene reactor. Under airtight conditions, React at 150°C for 3 hours; after the reaction is complete, filter the reaction mixture, and then wash the filtered solids with distilled water and absolute ethanol for 3 times, and then dry the washed solids at 70°C and grind. Obtain a niobium oxide precursor with an average particle size of 4nm;

[0052] Put the niobium oxide precursor and red phosphorus into a ceramic crucible at a mass ratio of 1:6, and place them in the downstream and upstream of the vacuum atmosphere tube furnace. The distance between the niobium oxide precursor and red phosphorus is 65cm, in an inert gas atmosphere (argon), heat the upstream area to 450°C at a rate of 2°C / min, and keep it for 3 hours; then in an inert gas atmosphere (argon), at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com