Method for efficiently removing galaxolide in water

A technology for carol musk and water removal, applied to chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems that the adsorption capacity of organic pollutants needs to be improved, and achieve fast processing time, large adsorption capacity, The effect of the treatment effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0037] Preparation of biochar materials

[0038] Wheat (WS) and rice husk (RH) straws were dried and crushed to a particle size of 2 mm, and 12 g of crushed wheat straw was weighed in a ceramic crucible (as full as possible to reduce the presence of oxygen), and placed in an oven (DGG-9023A , Shanghai Senxin Experimental Instrument Co., Ltd., China) and dried at 80 °C for 24 h. Nitrogen was applied to the surface of the dried wheat straw 2To remove oxygen, seal the ceramic crucible with aluminum foil paper (limited oxygen), place the ceramic crucible in a muffle furnace (SX-GO7102, Tianjin Zhonghuan Experimental Electric Furnace Co., Ltd., China) and crack in C1 Oxygen cracking at low temperature for 2h. After the cracking, wash repeatedly with distilled water until the pH of the cleaning solution is neutral. After washing, put it in an oven and dry it at 80°C for 24 hours to obtain biochar, which is stored for future use. Among them, the C1 value and the obtained biochar ar...

Embodiment 7~12

[0043] Preparation of ball-milled biochar

[0044] The biochar that above-mentioned embodiment 1~6 obtains is placed in the agate jar of 500mL, all puts 1.8g biochar and 180g diameter in each jar and is the agate ball of 6mm, puts into planetary ball mill after agate jar is sealed , ball milled at room temperature at 300 rpm for 12 hours, and switched the direction of rotation every 30 minutes. The nomenclature of the ball-milled biochar is shown in Table 2.

[0045] The biochar obtained in Table 2 Examples 1 to 6 is ball-milled to obtain ball-milled biochar

[0046]

[0047]

Embodiment 13

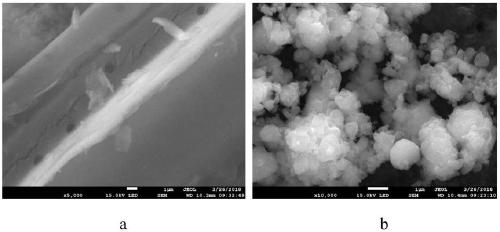

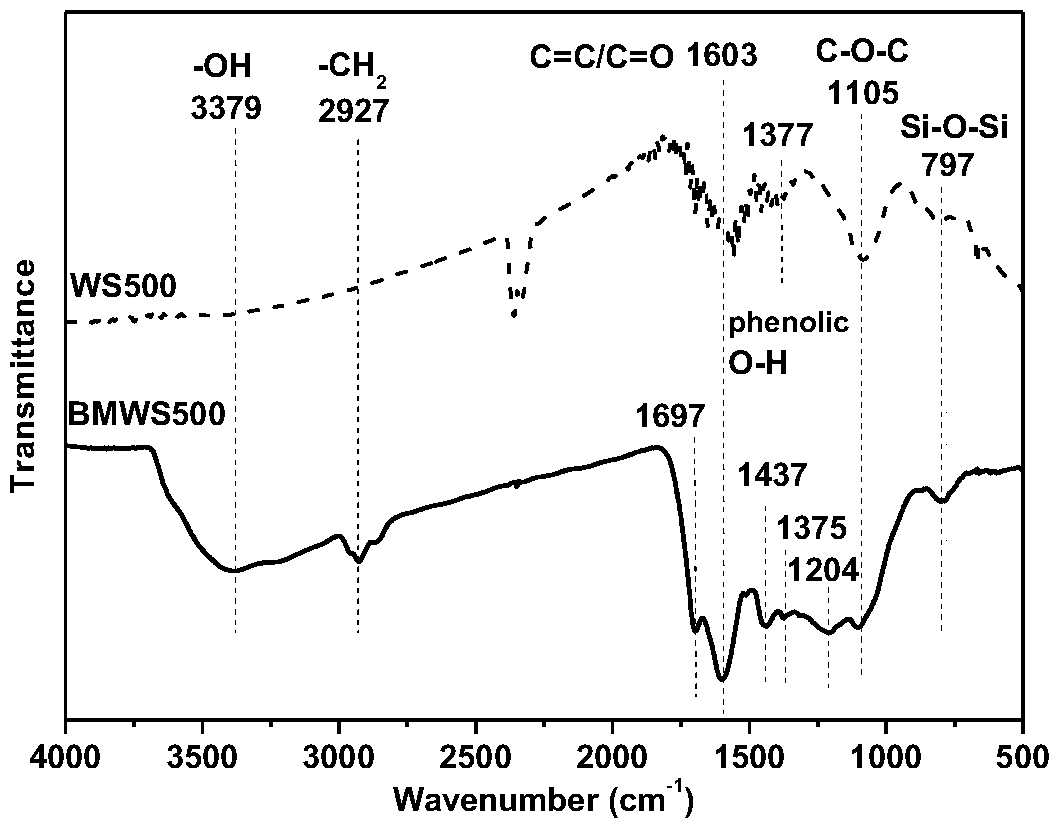

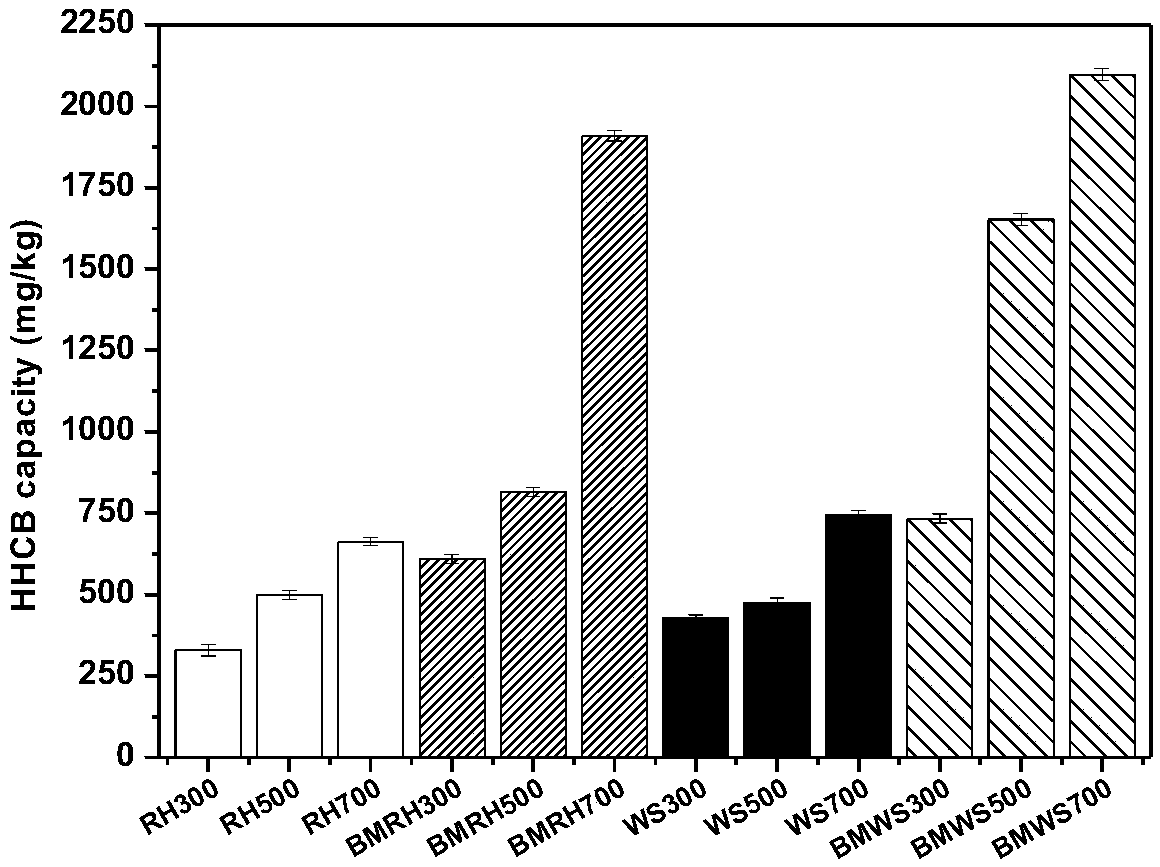

[0049] The effect of ball milling on the properties of biochar:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com