Denitrification biological film nitrogen removal bioreactor and using method and application thereof

A bioreactor, denitrifying microorganism technology, applied in chemical instruments and methods, biological treatment devices, biological water/sewage treatment, etc., can solve the problem of high cost, achieve removal, improve operation stability and denitrification efficiency, The effect of promoting biodegradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

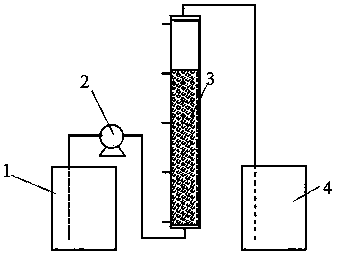

Image

Examples

Embodiment 1

[0021] The influent water is groundwater in Beijing, adding NaNO 3 Make the concentrations 50 mg / L and adjust the pH of the influent to 7.5. Carry out denitrification treatment according to the following steps:

[0022] (1) Start-up of the reactor:

[0023] Fill the PBS granules in the packed bed of the reactor, the filling height is 75% of the height of the reactor, adopt the bottom water inlet method, inoculate denitrifying microorganisms, adjust the temperature at 25°C-30°C, and wait for the denitrification effect to stabilize (outlet The nitrate concentration in the water is in a steady state), and the reactor start-up is completed.

[0024] (2) Operation of the reactor:

[0025] After the reactor is started up, it starts to operate normally, the operating temperature is 15°C-40°C, the water containing nitrate enters the denitrification biofilm denitrification reactor, the flow rate of the water is adjusted by the water pump, and the hydraulic retention time is 1 h-3 h ...

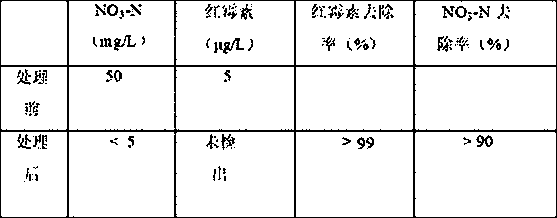

Embodiment 2

[0030] The influent water is groundwater in Beijing, adding NaNO 3 and 2,4-DCP (2,4-dichlorophenol) at concentrations of 50 mg / L and 10 μg / L, respectively. Process according to the steps of Example 1, and the water quality before and after treatment is as shown in Table 2.

[0031] Table 2 Water quality changes before and after treatment

[0032]

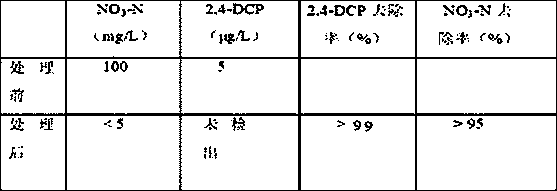

Embodiment 3

[0034] The influent water is groundwater in Beijing, adding NaNO 3 and 2,4-DCP (2,4-dichlorophenol) at concentrations of 100 mg / L and 5 μg / L, respectively. Process according to the steps of Example 1, and the water quality before and after treatment is as shown in Table 3.

[0035] Table 3 Water quality changes before and after treatment

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com