Degradable moisture retention mulching film and method for preparing same

A technology of mulch film and coating liquid, which is applied in the field of agricultural planting, can solve the problems of blocked soil moisture and nutrient transportation, poor water absorption and moisture retention performance of mulch film, and malnutrition of crops, so as to inhibit the growth of miscellaneous bacteria and improve anti-aging performance , Good water absorption and moisturizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

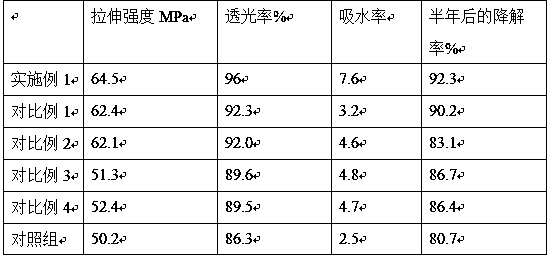

Examples

Embodiment 1

[0020] A degradable moisture-retaining plastic film, the components by weight are as follows: 20 parts of chitosan, 4 parts of acrylamide, 3 parts of p-aminobenzenesulfonic acid, 1 part of aluminum oxide, 45 parts of tetrahydrofuran, 20 parts of polylactic acid, polyethylene 6 parts of alcohol, 5 parts of polycaprolactone, 3 parts of polyethylene glycol, 40 parts of petroleum ether, 4 parts of low-density polyethylene, 3 parts of lauryl alcohol ester, 2 parts of Chinese medicine extract, and 1 part of nano-titanium dioxide.

[0021] As a preference, wherein the Chinese medicine extract is mixed with Coptidis Rhizoma, Bupleurum, and Scutellaria Scutellariae in a weight ratio of 1:1:1, then added to 2 times the amount of water, boiled with strong fire, decocted with slow fire for 30 minutes, and then Prepared by filtration.

[0022] A preparation method of a degradable moisture-retaining film, the specific steps are as follows:

[0023] 1) Take 20 parts of chitosan, add it to 2...

Embodiment 2

[0029] A degradable moisture-retaining plastic film, the components by weight are as follows: 25 parts of chitosan, 4 parts of acrylamide, 3 parts of p-aminobenzenesulfonic acid, 1 part of aluminum oxide, 47 parts of tetrahydrofuran, 23 parts of polylactic acid, polyethylene 6 parts of alcohol, 5 parts of polycaprolactone, 3 parts of polyethylene glycol, 45 parts of petroleum ether, 4 parts of low-density polyethylene, 3 parts of lauryl alcohol ester, 2 parts of Chinese medicine extract, and 1 part of nano-titanium dioxide.

[0030] As a preference, wherein the Chinese medicine extract is mixed with Coptidis Rhizoma, Bupleurum, and Scutellaria Scutellariae in a weight ratio of 1:1:1, then added to 2 times the amount of water, boiled with strong fire, decocted with slow fire for 35 minutes, and then Prepared by filtration.

[0031] A preparation method of a degradable moisture-retaining film, the specific steps are as follows:

[0032] 1) Take 25 parts of chitosan, add it to 2...

Embodiment 3

[0038] A degradable moisture-retaining plastic film, the components by weight are as follows: 30 parts of chitosan, 5 parts of acrylamide, 4 parts of p-aminobenzenesulfonic acid, 2 parts of aluminum oxide, 50 parts of tetrahydrofuran, 25 parts of polylactic acid, polyethylene 7 parts of alcohol, 6 parts of polycaprolactone, 4 parts of polyethylene glycol, 50 parts of petroleum ether, 5 parts of low-density polyethylene, 4 parts of lauryl alcohol ester, 3 parts of Chinese medicine extract, and 2 parts of nano-titanium dioxide.

[0039] As a preference, wherein the Chinese medicine extract is mixed with Coptidis Rhizoma, Bupleurum, and Scutellaria Scutellariae in a weight ratio of 1:1:1, then added to 3 times the amount of water, boiled with strong fire, decocted with slow fire for 40 minutes, and then Prepared by filtration.

[0040] A preparation method of a degradable moisture-retaining film, the specific steps are as follows:

[0041] 1) Take 30 parts of chitosan, add it to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com