A kind of 12crni3a carburizing and quenching method

A technology of carburizing and quenching and carbon potential, which is applied in the direction of solid-state diffusion coating, coating, metal material coating technology, etc., can solve the problems that product quality cannot be effectively controlled, the environment and human body are harmful, and human control factors are large. , to achieve the effects of improved production environment, less environmental and human hazards, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

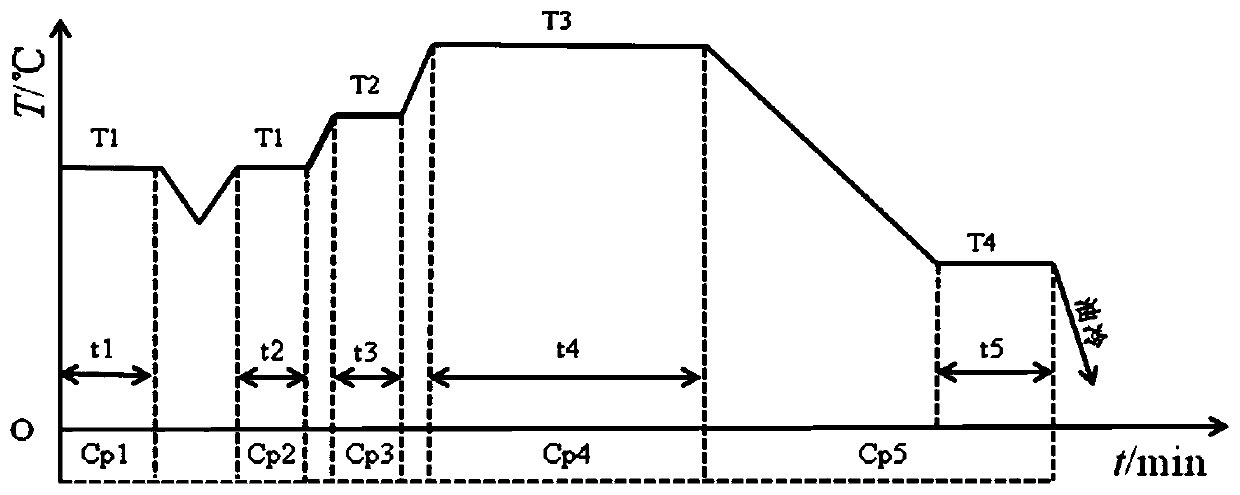

[0020] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings, but the required protection scope is not limited to the description;

[0021] like figure 2 Shown, a kind of 12CrNi3A carburizing and quenching method comprises the steps:

[0022] (1) Forging 12CrNi3A bar stock, processed into gear parts after quenching and tempering;

[0023] (2) Create the atmosphere: the carburizing furnace is kept at (820-840) °C and 1.4% C (corresponding to Cp1 in the figure) for (1-2) h;

[0024] (3) The workpiece is put into the furnace;

[0025] (4) After the parts are loaded into the furnace, keep them warm for (30-50) min at (820-840) °C and 1.4% C (corresponding to Cp2 in the figure);

[0026] (5) Heat up to (850-870) °C and keep warm for (30-50) min at 1.4% C (corresponding to Cp3 in the figure);

[0027] (6) Raise the temperature to (880-910) ° C, keep 1.4% C (corresponding to Cp4 in the figure), and adjust the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com