Preparation method of modified lithium nickel manganese oxide

A lithium nickel manganese oxide and modification technology, which is applied in the field of preparation of modified lithium nickel manganese oxide, can solve the problems affecting the internal demand of lithium nickel manganese oxide, difficult to mix raw material components uniformly, and expensive raw material reagents, etc., to increase capacity As well as the effects of rate performance, short calcination time, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

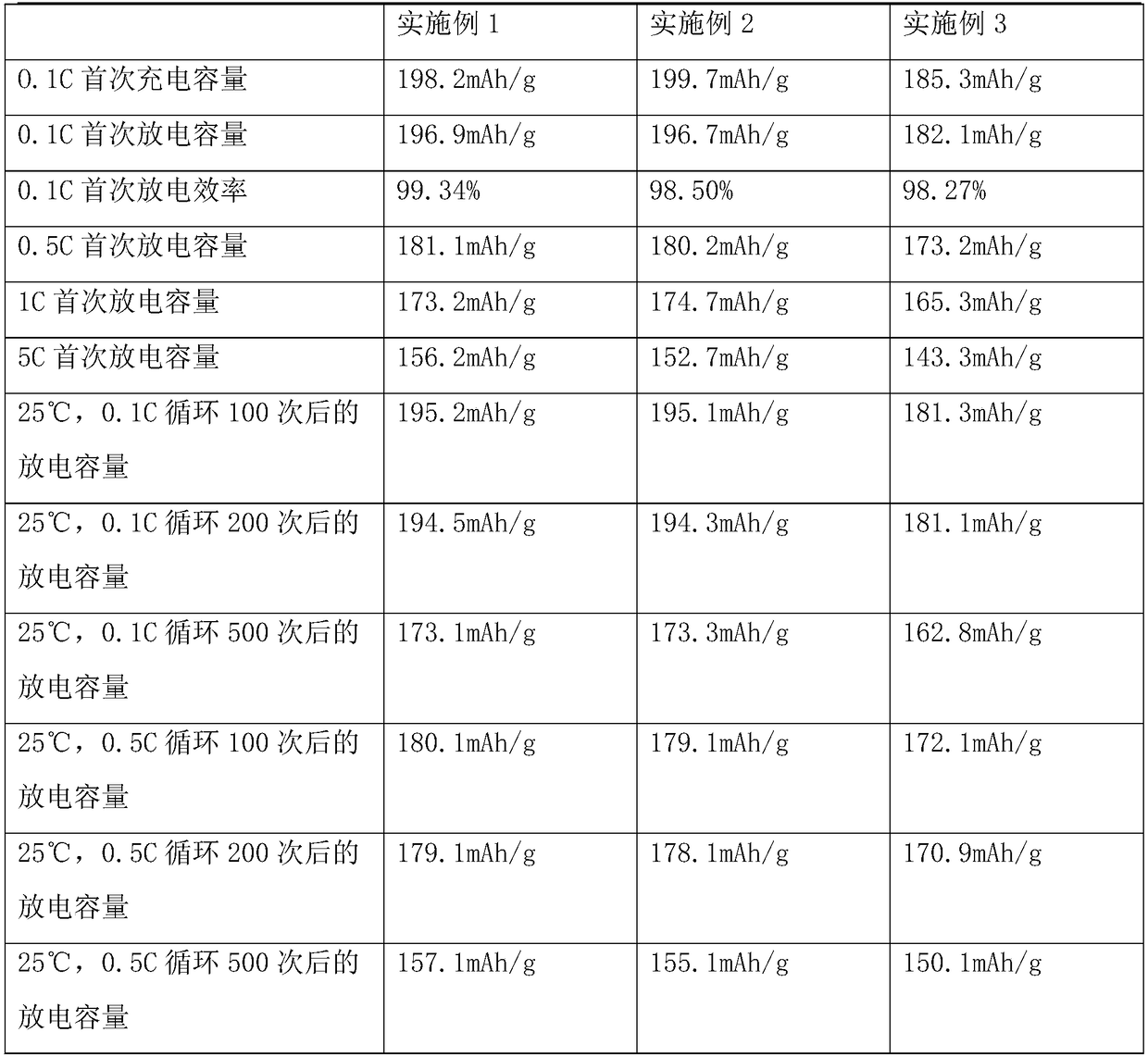

Examples

Embodiment 1

[0041] A preparation method of modified lithium nickel manganese oxide, which comprises the following steps:

[0042] (1) LiMnO 4 Add pure water and nickel acetate, stir and dissolve at normal temperature, and then spray dry to obtain a mixture;

[0043] (2) Reaction, put the mixed material into the roller furnace for calcination, the calcination temperature is 830°C, the calcination time is 4.5h, the air is introduced into the calcination process, and the oxygen volume fraction in the roller furnace is maintained at 18%, and after cooling, it is obtained coolant;

[0044] (3) adding lithium acetate, lanthanum acetate, vanadium acetate, titanium dioxide and aluminum oxide to the cooling material, then slurrying, grinding to a particle size of 550nm, and spray drying to obtain the second mixture;

[0045] (4) Put the second mixture into the roller furnace for secondary calcination. The calcination temperature is 785°C, and the calcination time is 2.7h. After being pulverized ...

Embodiment 2

[0054] A preparation method of modified lithium nickel manganese oxide, which comprises the following steps:

[0055] (1) LiMnO 4 Add pure water and nickel acetate, stir and dissolve at normal temperature, and then spray dry to obtain a mixture;

[0056] (2) Reaction, put the mixed material into the roller furnace for calcination, the calcination temperature is 835°C, the calcination time is 4.7h, air is introduced into the calcination process, and the oxygen volume fraction in the roller furnace is maintained at 17%, and after cooling, it is obtained coolant;

[0057] (3) adding lithium acetate, lanthanum acetate, vanadium acetate, titanium dioxide and aluminum oxide to the cooling material, then slurrying, grinding to a particle size of 590nm, and spray drying to obtain the second mixture;

[0058] (4) Put the second mixture into the roller furnace for secondary calcination. The calcination temperature is 770°C, and the calcination time is 2.3h. After being pulverized by a...

Embodiment 3

[0067] A preparation method of modified lithium nickel manganese oxide, which comprises the following steps:

[0068] (1) LiMnO 4 Add pure water and nickel acetate, stir and dissolve at normal temperature, and then spray dry to obtain a mixture;

[0069] (2) Reaction, put the mixed material into the roller furnace for calcination, the calcination temperature is 845°C, the calcination time is 4.5h, air is introduced into the calcination process, and the oxygen volume fraction in the roller furnace is maintained to be 19%, and after cooling, it is obtained coolant;

[0070] (3) adding lithium acetate, lanthanum acetate, vanadium acetate, titanium dioxide and aluminum oxide to the cooling material, then slurrying, grinding to a particle size of 620nm, and spray drying to obtain the second mixture;

[0071] (4) Put the second mixture into the roller furnace for secondary calcination. The calcination temperature is 775°C, and the calcination time is 2.7h. After being pulverized b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com