High-efficiency adsorption material for flue gas purification

An adsorption material and flue gas purification technology, applied in other chemical processes, chemical instruments and methods, combined devices, etc., can solve the problems of energy consumption, high difficulty in adsorbent development, increase in flue gas treatment costs, etc., and achieve good adsorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

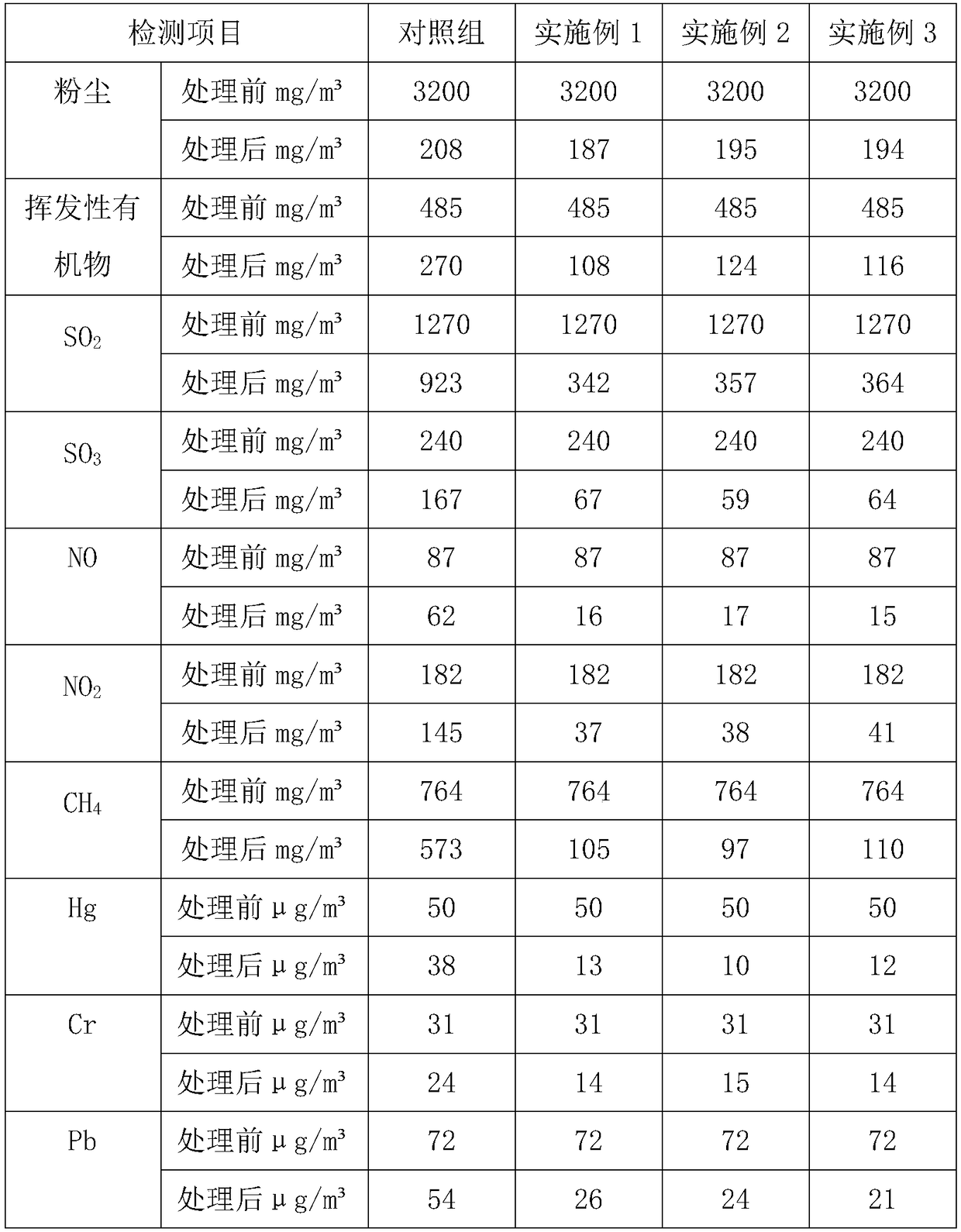

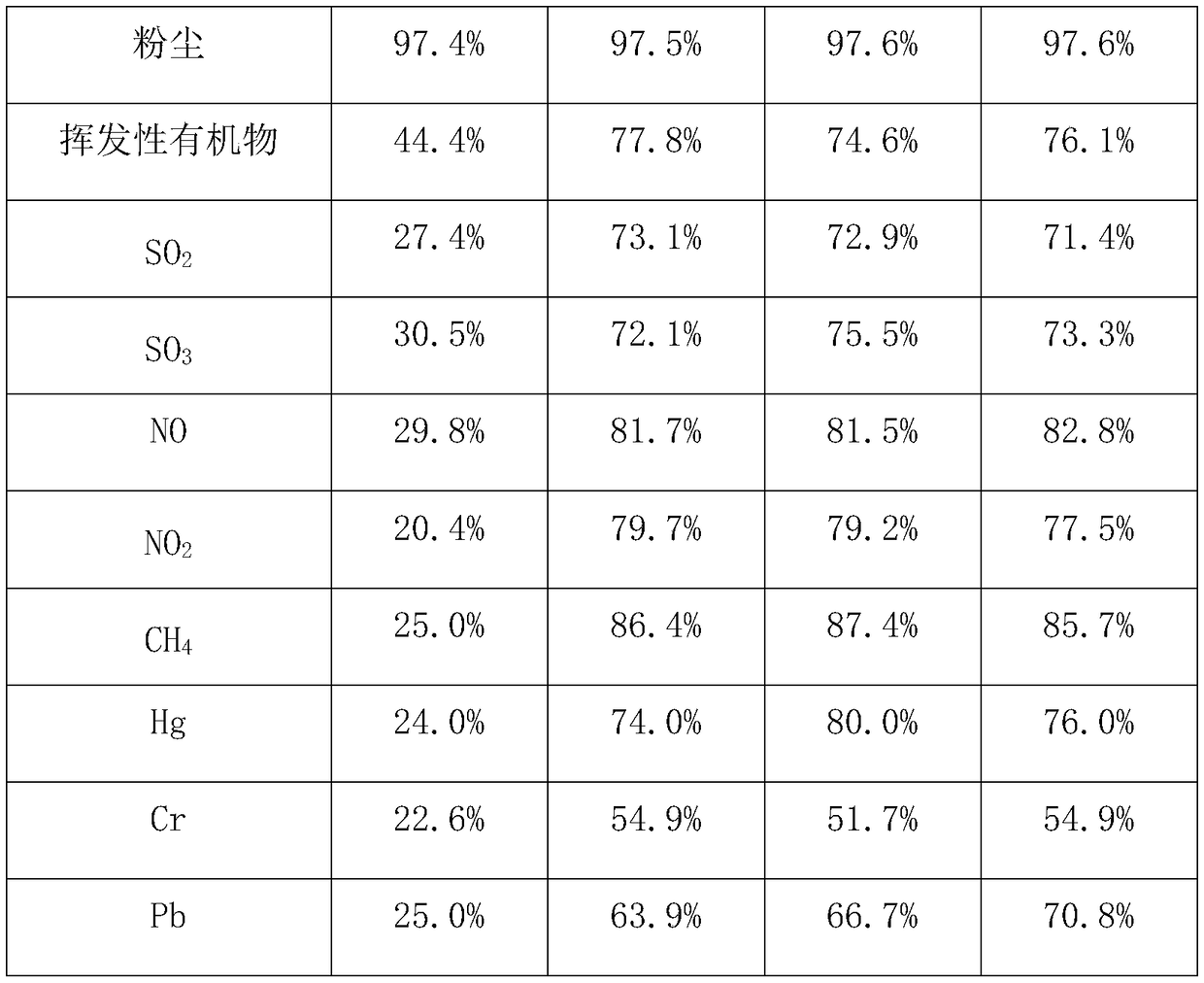

Embodiment 1

[0031] A high-efficiency adsorption material for flue gas purification, the adsorption material is composed of a catalytic adsorption carrier and an absorption layer attached to the surface of the catalytic adsorption carrier; according to the mass parts, the components of the catalytic adsorption carrier include: 80 parts of activated carbon, 40 parts of silicon nitride, 20 parts of zeolite powder, 12 parts of titanium dioxide, 6 parts of aluminum sulfate, 2 parts of nano zinc oxide, 6 parts of polyvinyl alcohol, 35 parts of water; the components of the absorption layer include: 30 parts of pregelatinized starch, 6 parts of dextran, 3 parts of ethylene urea, 2 parts of diethylenetriamine, 2 parts of histidine, 0.8 parts of nano silver colloid, 1.5 parts of dicumyl peroxide, 200 parts of deionized water.

[0032] Among the components, titanium dioxide is selected from anatase type titanium dioxide.

[0033] Dextran type α-glucan is selected as the dextran.

[0034] The prepar...

Embodiment 2

[0046] A high-efficiency adsorption material for flue gas purification, the adsorption material is composed of a catalytic adsorption carrier and an absorption layer attached to the surface of the catalytic adsorption carrier; in terms of parts by mass, the components of the catalytic adsorption carrier include: 95 parts of activated carbon, 45 parts of silicon nitride, 30 parts of zeolite powder, 18 parts of titanium dioxide, 10 parts of aluminum sulfate, 4 parts of nano zinc oxide, 8 parts of polyvinyl alcohol, 40 parts of water; the components of the absorption layer include: 40 parts of pregelatinized starch, 8 parts of dextran, 7 parts of ethylene urea, 5 parts of diethylene triamine, 3.6 parts of histidine, 1.7 parts of nano silver colloid, 2.3 parts of dicumyl peroxide, 260 parts of deionized water.

[0047] Among the components, titanium dioxide is selected from rutile type titanium dioxide.

[0048] Dextran type α-glucan is selected as the dextran.

[0049] The prepa...

Embodiment 3

[0061] A high-efficiency adsorption material for flue gas purification, the adsorption material is composed of a catalytic adsorption carrier and an absorption layer attached to the surface of the catalytic adsorption carrier; in parts by mass, the components of the catalytic adsorption carrier include: 88 parts of activated carbon, 43 parts of silicon nitride, 25 parts of zeolite powder, 14 parts of titanium dioxide, 8 parts of aluminum sulfate, 3.4 parts of nano zinc oxide, 7 parts of polyvinyl alcohol, 38 parts of water; the components of the absorption layer include: 36 parts of pregelatinized starch, 7 parts of dextran, 6 parts of ethylene urea, 3.5 parts of diethylenetriamine, 3.1 parts of histidine, 1.2 parts of nano-silver colloid, 1.9 parts of dicumyl peroxide, and 240 parts of deionized water.

[0062] Among the components, titanium dioxide is selected from anatase type titanium dioxide.

[0063] Dextran type α-glucan is selected as the dextran.

[0064] The prepara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com