Thixotropic and self-curing material for slip-form construction concrete and preparation method thereof

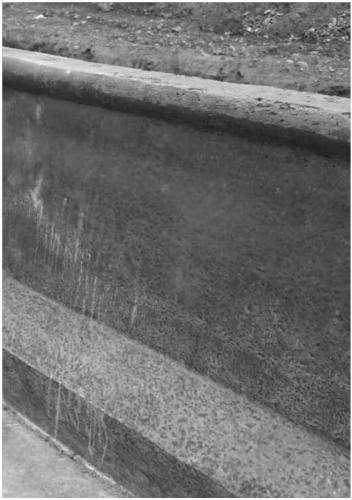

A technology of concrete and self-curing, which is applied in the preparation of the thixotropic and self-curing materials, and in the field of thixotropic and self-curing materials for slip-form construction concrete, which can solve the problems of difficult-to-shape concrete in slip-form construction, pockmarked concrete structures, and To prevent problems such as cracking, to achieve the effect of easy rapid prototyping of sliding mold, reduction of manual maintenance process, and good thixotropic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

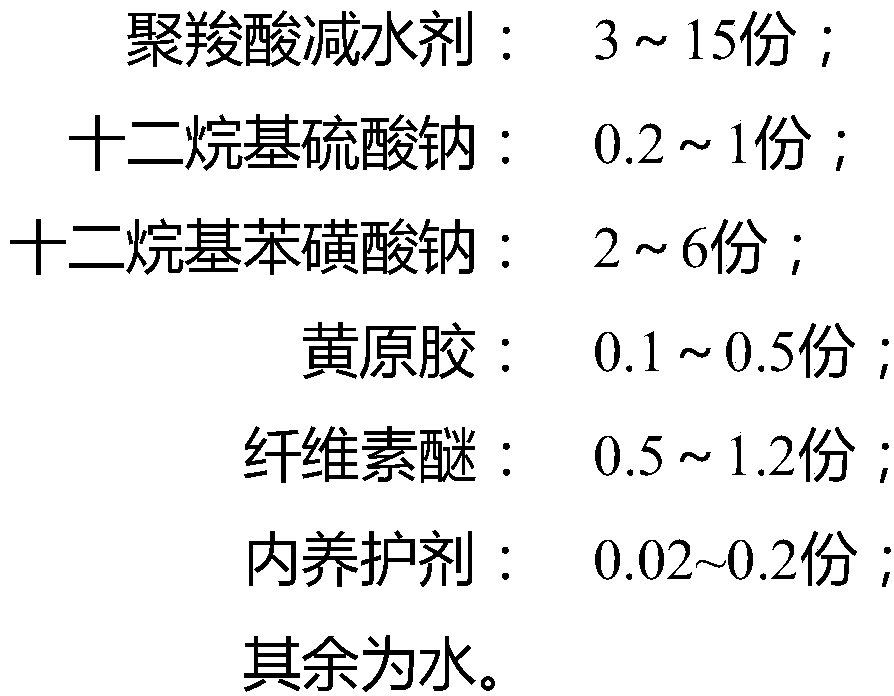

[0037] Thixotropic and self-curing materials are formulated as follows:

[0038] 20% polycarboxylate superplasticizer masterbatch: 12kg;

[0039] Sodium lauryl sulfate: 0.8kg;

[0040] Sodium dodecylbenzenesulfonate: 5kg;

[0041] Xanthan gum: 0.4kg;

[0042] Hydroxyethyl methyl cellulose ether: 1kg;

[0043] Warm rubber: 0.18kg;

[0044] Water: 980.62kg.

[0045] The preparation process is as follows: the xanthan gum, hydroxyethyl methyl cellulose ether and Wenlun gum in the components are first added to the water through sieve analysis and feeding method and stirred to dissolve evenly, and then polycarboxylate superplasticizer is added , Sodium dodecylsulfate and sodium dodecylbenzenesulfonate continue to stir, mixing and stirring for 50 minutes, until they dissolve into a uniform solution without agglomeration.

[0046] The slip form construction process is as follows:

[0047] (1) The C40 concrete mix ratio for the 1.18-meter-high anti-collision barrier is as follow...

Embodiment 2

[0063] Thixotropic and self-curing materials are formulated as follows:

[0064] 40% polycarboxylate superplasticizer masterbatch: 5kg;

[0065] Sodium lauryl sulfate: 0.5kg;

[0066] Sodium dodecylbenzenesulfonate: 3kg;

[0067] Xanthan gum: 0.2kg;

[0068] Hydroxypropyl methylcellulose ether: 0.7kg;

[0069] Modified starch ether: 0.05kg;

[0070] Water: 990.55kg.

[0071]The preparation process is as follows: the xanthan gum, hydroxypropyl methyl cellulose ether and modified starch ether in the components are first added into water by sieve analysis and feeding method, stirred to make them uniformly dissolved, and then polycarboxylate water-reducing The agent, sodium dodecylsulfate and sodium dodecylbenzenesulfonate continue to stir for 40 minutes until they dissolve into a uniform solution without agglomerates.

[0072] The slip form construction process is as follows:

[0073] (1) The C35 concrete mix ratio of 0.5m high drainage ditch is as follows:

[0074] P.O42...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com