Low reaction temperature phenolic resin grouting reinforcement material and preparation method thereof

A technology of reaction temperature and phenolic resin, which is applied in the field of low reaction temperature phenolic resin grouting reinforcement materials and its preparation, can solve the problems of unguaranteed use and untested toughening effect, so as to avoid poor toughness and superior durable resistance Effects of electrostatic properties, enhanced strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

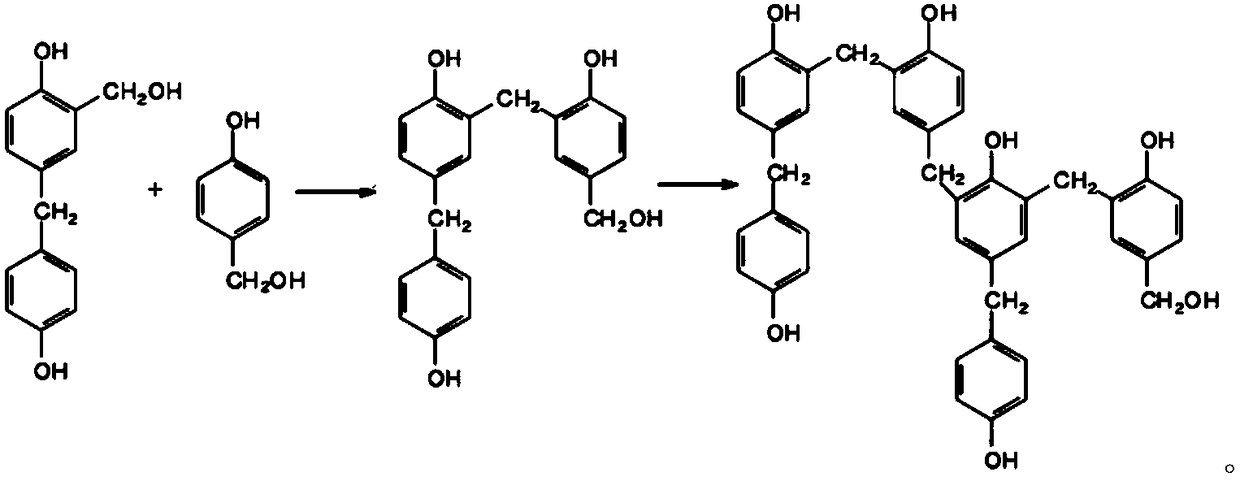

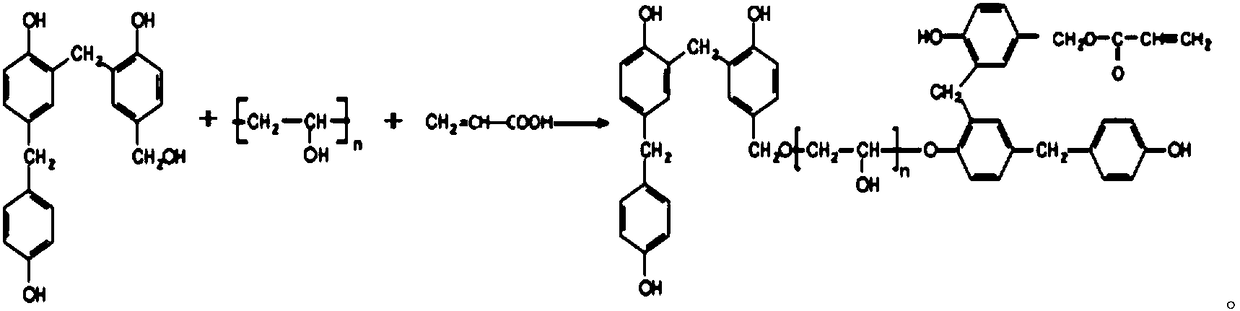

Method used

Image

Examples

Embodiment 1

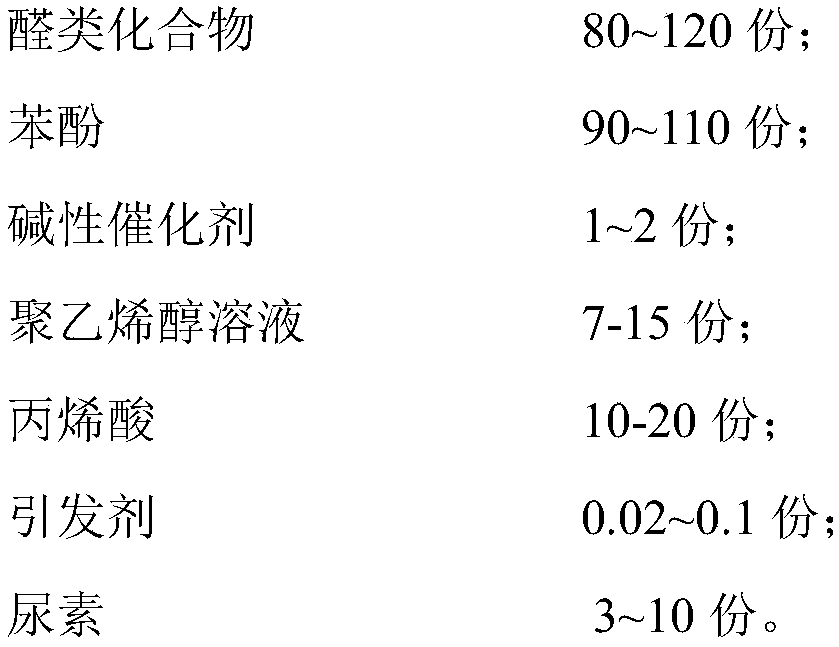

[0041] Weigh 120g of 37wt% formaldehyde solution, 110g of phenol, 1.5g of NaOH, 10g of acrylic acid, 15g of 5wt% polyvinyl alcohol solution and stir at 80°C for 2h, then add 0.02g of azobisisobutyronitrile and stir for 2h at 80°C , and then add 5g of urea and continue to keep warm for 1h to obtain component A; weigh 120g of p-toluenesulfonic acid, 60g of 85wt% phosphoric acid, and 20g of water and mix evenly to obtain component B.

[0042] Mix component A and component B uniformly according to the volume ratio A:B=4:1, and react to obtain low reaction temperature phenolic resin grouting reinforcement material.

Embodiment 2

[0044] Weigh 60g of glyoxal, 50g of glutaraldehyde, 100g of phenol, 1g of NaOH, 1g of triethanolamine, 20g of acrylic acid, 10g of 8wt% polyvinyl alcohol solution and stir at 80°C for 2h, then add 0.1g of azobisisobutyronitrile Stir and react at 80°C for 2 hours, then add 3g of urea and keep warm for 1 hour to obtain component A; weigh 120g of p-toluenesulfonic acid, 60g of 85% phosphoric acid, and 20g of water and mix evenly to obtain component B.

[0045] Mix component A and component B uniformly according to volume ratio A:B=4:1, and react to obtain low reaction temperature phenolic resin grouting reinforcement material.

Embodiment 3

[0047] Weigh 40g of 37wt% formaldehyde solution, 40g of paraformaldehyde, 90g of phenol, 0.5g of NaOH, 0.5g of triethylamine, 0.5g of glyoxal, 15g of acrylic acid, 8g of 10wt% polyvinyl alcohol solution and stir at 80°C for 2h. Then add 0.05g of azobisisobutyronitrile, stir and react at 80°C for 2h, then add 10g of urea and keep warm for 1h to obtain component A; weigh 100g of p-toluenesulfonic acid, 50g of 38% hydrochloric acid, and 20g of water and mix evenly. That is, component B is obtained.

[0048] Mix component A and component B uniformly according to volume ratio A:B=2:1, and react to obtain low reaction temperature phenolic resin grouting reinforcement material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com