Industrial production method of high-purity linear phenolic resin

A novolac resin and production method technology, which is applied in the refining process field of novolac resin, can solve the problems of not being able to meet the purity requirements of novolac resin, difficult engineering scale-up and continuous production, and vague description, so as to reduce the generation of waste water Quantity, material residence time is short, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

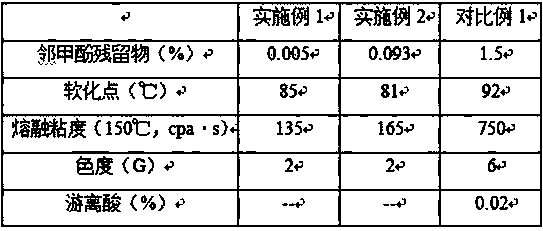

Examples

Embodiment 1

[0035] An industrial production method of high-purity novolac resin, the steps are as follows: (1) Measure 108kg of phenol through a mass flow meter, put the delivery pump into the reaction kettle, start stirring at a speed of 60 rpm, and then add 1kg For oxalic acid, when the temperature was raised to 90° C., 73 kg of formaldehyde solution with a mass fraction of 37% was added dropwise to the reactor by a mass flow meter, and the titration was complete within 2 hours;

[0036] (2) After adding formaldehyde aqueous solution dropwise, keep the reaction at 100 ℃ for 6 hours, and then add oxalic acid until the pH of the mixed solution in the reaction kettle is 4~6;

[0037] (3) Continue to add 100Kg of solvent to the reaction kettle, and maintain the temperature of the kettle material at 79~81°C;

[0038] (4) Transfer all the materials in the reaction kettle in step (3) to the extraction kettle, add 70kg of water at 70~90°C to the extraction kettle, stir and wash for 30 minutes, ...

Embodiment 2

[0050] An industrial production method of high-purity novolac resin, the steps are as follows: (1) Measure 94kg of phenol through a mass flow meter, put the delivery pump into the reaction kettle, start stirring at a speed of 70 rpm, and then add 1kg For oxalic acid, when the temperature was raised to 90° C., 68 kg of formaldehyde solution with a mass fraction of 37% was added dropwise to the reactor by a mass flow meter, and the titration was complete within 2 hours;

[0051] (2) After adding formaldehyde aqueous solution dropwise, keep the reaction at 95 ℃ for 8 hours, and then add oxalic acid until the pH of the mixed solution in the reaction kettle is 4~6;

[0052] (3) Continue to add 80kg of solvent to the reaction kettle, and maintain the temperature of the kettle material at 80°C;

[0053] (4) Transfer all the materials in the reaction kettle in step (3) into the extraction kettle, add 70kg of water at 90°C to the extraction kettle, stir and wash with water for 30 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com