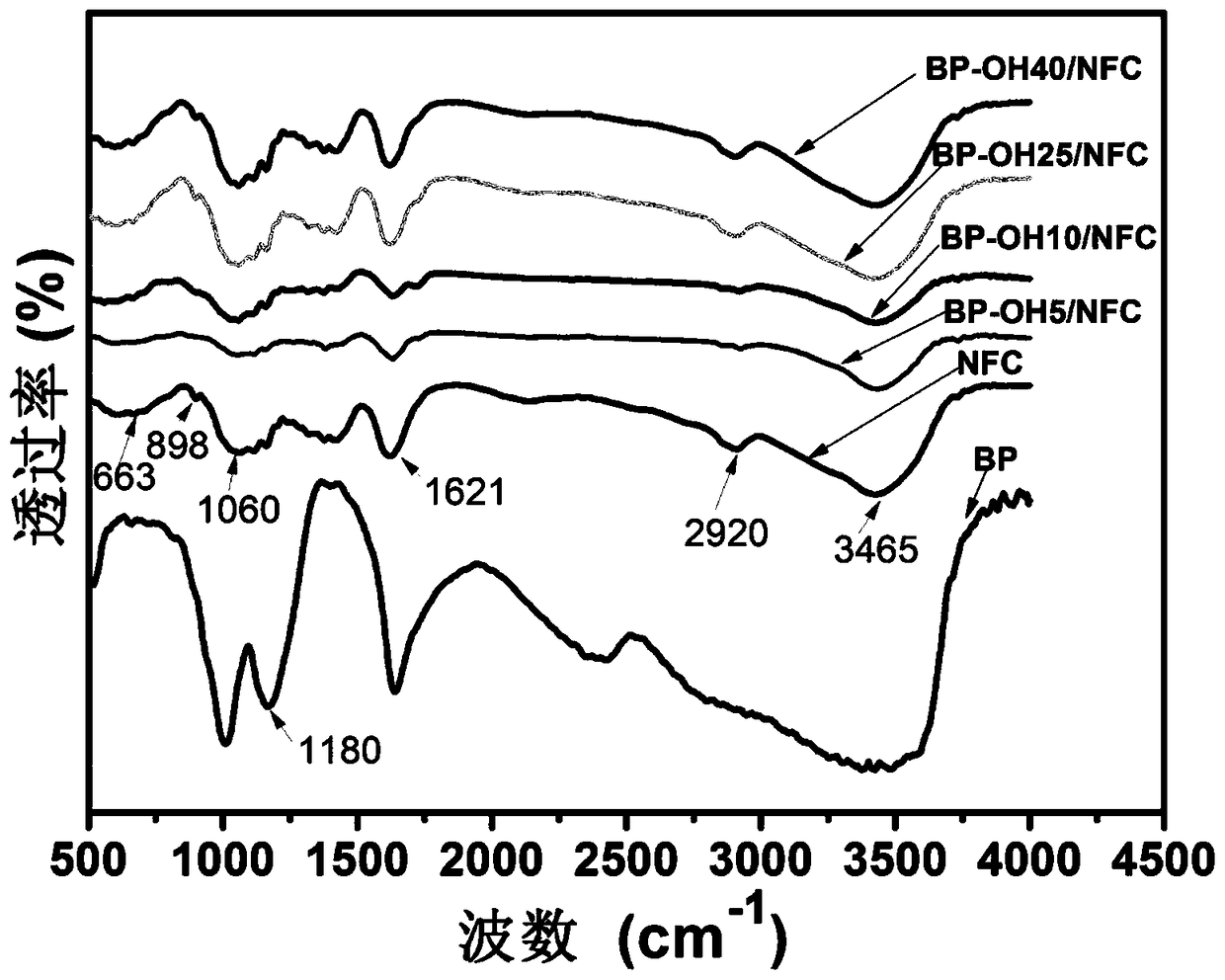

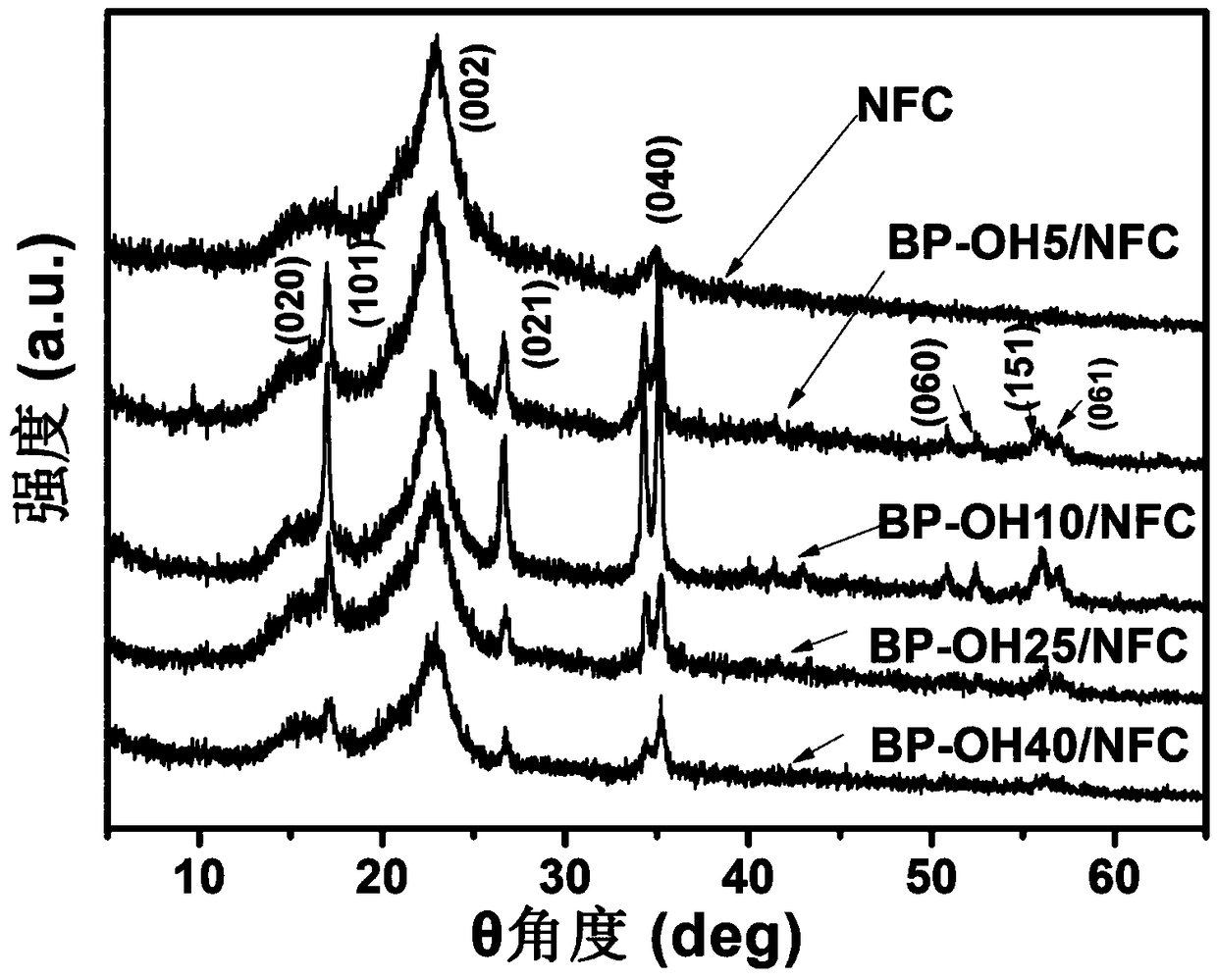

Preparation method of shell-like structure cellulose nanofiber/black phosphorene composite film

A nanofiber and cellulose technology, applied in the field of bionics, can solve the problems of no preparation method of phosphorene-cellulose nanofiber composite film, no good treatment method, poor mechanical properties of the film, etc., and achieve high strength and low cost. , the effect of uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this example, the preparation steps of the shell-like structure cellulose nanofiber / black phosphorene composite film are as follows:

[0038] 1. Preparation of cellulose nanofiber dispersion

[0039] Take 1g of cotton linters, 0.01gTEMPO and 0.1gNaBr into 500mL of deionized water, then add 0.1g of NaClO to the system, and adjust the pH value of the system to about 9 through NaOH solution. After 6 hours of reaction, the oxidized fiber The obtained oxidized cellulose was dispersed in deionized water and ultrasonically stirred for 30 min to obtain a cellulose nanofiber dispersion with a concentration of 0.5%.

[0040] 2. Preparation of Hydroxylated Black Phosphorus

[0041] First mix 500mg of red phosphorus, 120mg of tin powder and 30mg of tin iodide according to a certain ratio, put them in a mortar, crush them and mix them evenly, then seal the tube, and encapsulate the above mixed powder into a certain size of quartz in an argon atmosphere. Then put the above-mention...

Embodiment 2

[0053] In this example, the preparation steps of the shell-like structure cellulose nanofiber / black phosphorene composite film are as follows:

[0054] 1. Preparation of NFC dispersion

[0055] Take 1g of cotton linters, 0.01g of TEMPO and 0.1g of NaBr, and add the above materials into 500mL of deionized water, then add 0.1g of NaClO to the system, and adjust the pH value of the system to about 9 through NaOH solution. After 6 hours of reaction Filter the oxidized cellulose and wash it with deionized water several times to obtain TEMPO oxidized cellulose; disperse the obtained oxidized cellulose in deionized water, and stir it ultrasonically for 30 minutes to obtain a cellulose nanofiber dispersion with a concentration of 0.5%. , which is 0.5% NFC dispersion.

[0056] 2. Preparation of hydroxylated black phosphorus

[0057] First mix 500mg of red phosphorus, 120mg of tin powder and 30mg of tin iodide according to a certain ratio, put them in a mortar, crush them and mix them...

Embodiment 3

[0063] In this example, the preparation steps of the shell-like structure cellulose nanofiber / black phosphorene composite film are as follows:

[0064] 1. Preparation of NFC dispersion

[0065] Take 1g of cotton linters, 0.01g of TEMPO and 0.1g of NaBr, and add the above materials into 500mL of deionized water, then add 0.1g of NaClO to the system, and adjust the pH value of the system to about 9 through NaOH solution. After 6 hours of reaction Filter the oxidized cellulose and wash it with deionized water several times to obtain TEMPO oxidized cellulose; disperse the obtained oxidized cellulose in deionized water, and stir it ultrasonically for 30 minutes to obtain a cellulose nanofiber dispersion with a concentration of 0.5%. , which is 0.5% NFC dispersion.

[0066] 2. Preparation of hydroxylated black phosphorus

[0067] First mix 500mg of red phosphorus, 120mg of tin powder and 30mg of tin iodide according to a certain ratio, put them in a mortar, crush them and mix them...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com