QFN (quad flat no-lead package) adhesive removal and softening integrated soak solution

A soaking liquid, integrated technology, applied in chemical instruments and methods, polymer surface active compounds, detergent compounding agents, etc., can solve the problems of negative impact of plastic body and frame, impact on productivity, impact on softening potion performance, etc., to achieve easy Good effect of cleaning, increasing productivity, degumming and softening ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

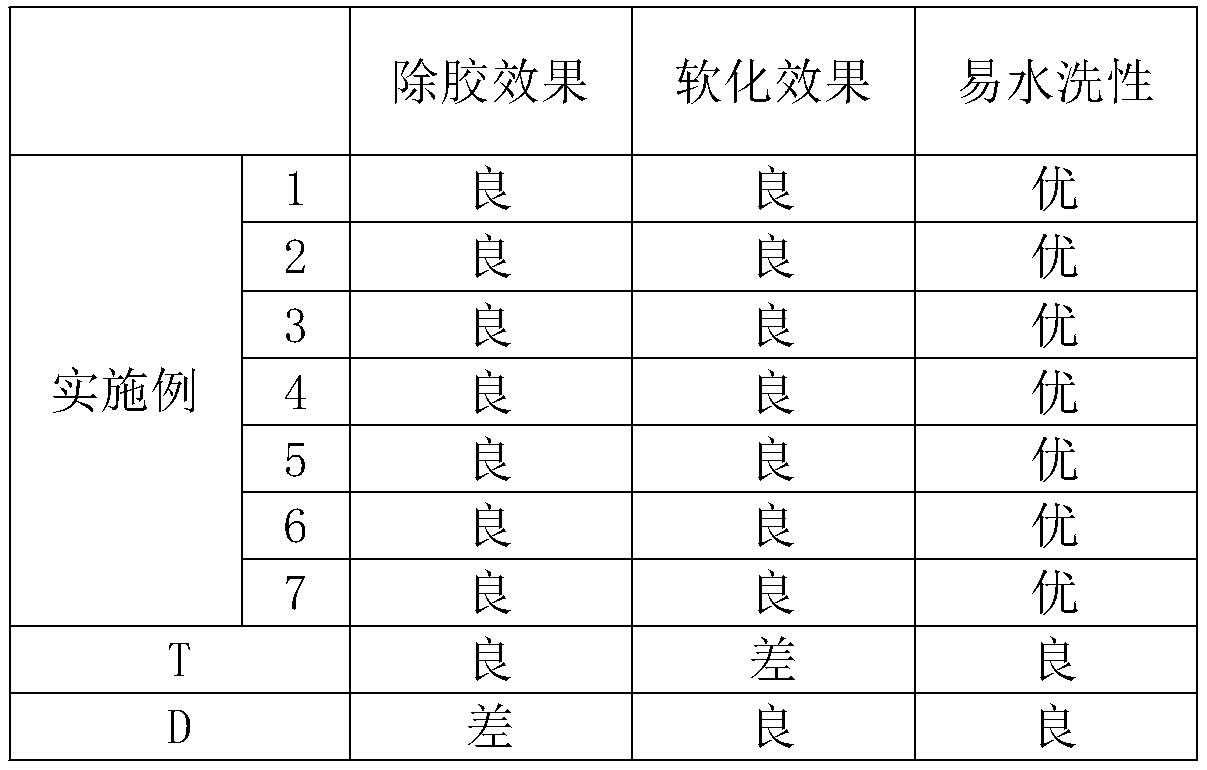

Examples

Embodiment 1

[0027] 0.5wt% block polyether surfactant A (2,40), 20wt% ethanolamine, 0.1wt% sodium hydroxide, 30wt% tert-butyl acetate, 25wt% propylene glycol methyl ether, 0.01wt% benzotriazole and the remainder of deionized water.

Embodiment 2

[0029] 1wt% block polyether surfactant A (40,2), 23wt% tetramethylammonium hydroxide, 0.3wt% sodium carbonate, 50wt% isoamyl acetate, 15wt% ethylene glycol butyl ether, 15wt% ethyl Glycol methyl ether, 0.02wt% tolyltriazole and the balance of deionized water.

Embodiment 3

[0031] 5wt% block polyether surfactant A (20,11), 20wt% tetraethylammonium hydroxide, 20wt% ethylenediamine, 2wt% sodium citrate, 21wt% butyl propionate, 14wt% methyl butyrate ester, 14wt% ethylene glycol dimethyl ether, 14wt% ethylene glycol dibutyl ether, 0.03wt% tetrazolium sulfhydryl and the balance of deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com