Preparation method of cubic pyrochlore phase nanofiber based on electrospinning method and application thereof

A technology of cubic pyrochlore and electrospinning, which is applied in the preparation of spinning solutions, rayon of inorganic raw materials, etc., to achieve the effects of good repeatability, simplifying the double-doping or multi-doping process, and meeting the requirements of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A method for preparing cubic pyrochlore phase nanofibers based on an electrospinning method of the present invention comprises the following steps:

[0037] S1, DMF and acetic acid are mixed and stirred according to the mass ratio of 1:(0.3~0.6), to obtain solution A;

[0038] S2. During continuous stirring, tetrabutyl titanate with a mass ratio of 1: (1.5-2) to solution A is added to solution A to obtain solution B;

[0039] S3, adding erbium nitrate with solution B in a mass ratio of 1: (14 to 32) into solution B to obtain solution C in the process of constant stirring;

[0040] S4, adding bismuth nitrate with a mass ratio of 1: (15 to 34) to solution C during continuous stirring to obtain solution D;

[0041] S5. Add 5-10% (mass fraction) of PVP to the solution C and stir to form an electrospinning precursor solution;

[0042] S6. In the case of applying a high-voltage power supply of 18-25 kV, spray the precursor liquid onto the collector through a micro-flow prec...

Embodiment 1

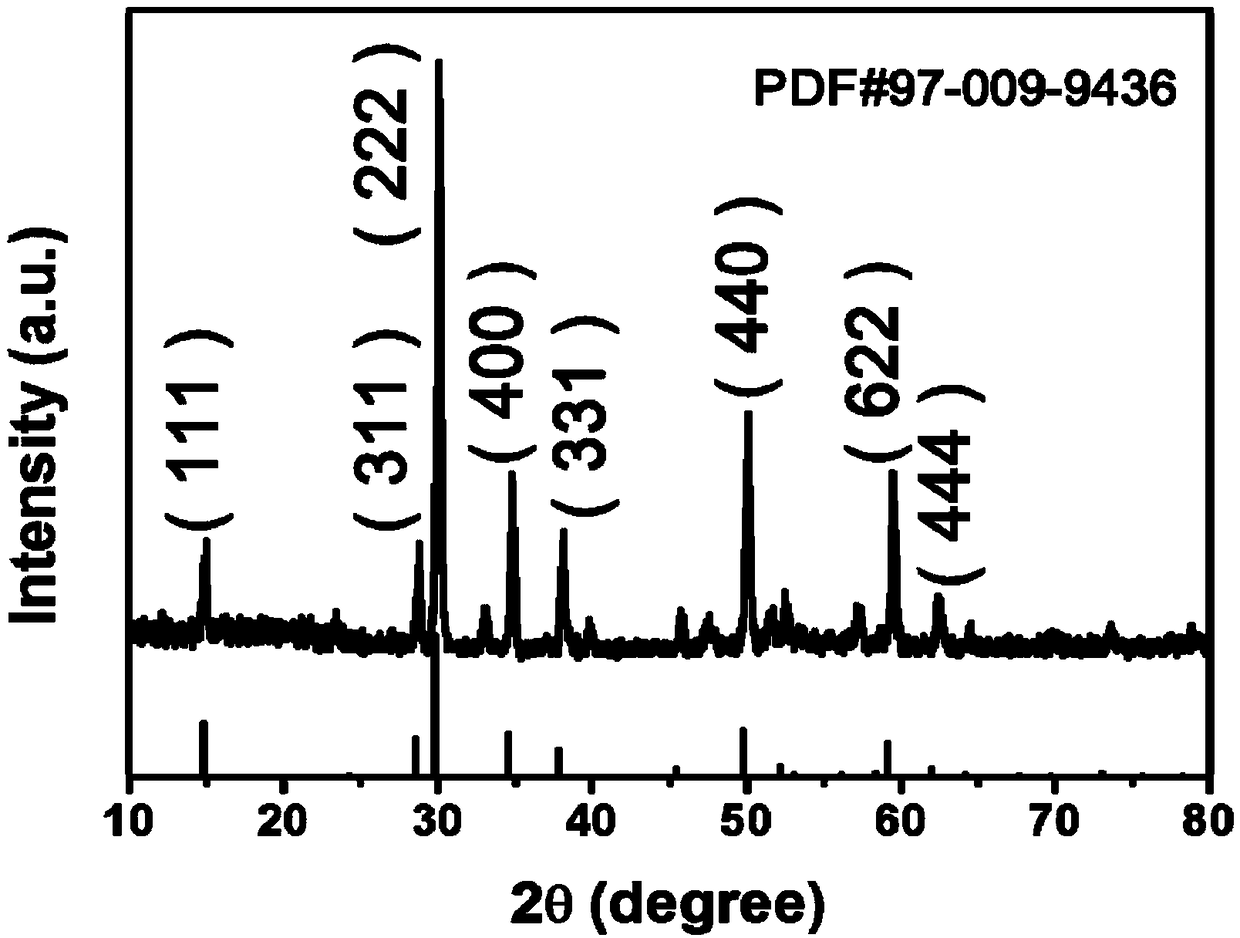

[0049] DMF and acetic acid were mixed in a mass ratio of 0.3:1, and a transparent solution was formed by magnetic stirring; then 0.8ml of tetrabutyl titanate was added and fully dissolved by stirring; 0.11g of erbium nitrate was added under rapid stirring; After it was fully dissolved, 1.05 g of bismuth nitrate was added and fully stirred to dissolve it, and finally PVP with a mass fraction of 5% was added, and an electrospinning precursor was obtained after magnetic stirring. Under the control voltage of 18KV and the flow rate of 10μl / m, a large amount of nanomaterials appeared on the collector. After the electrospinning was completed, the nanomaterials on the collector were transferred to the muffle furnace and heated at 4°C / min. If the rate is increased to 600°C for 1 hour, the pyrochlore phase Bi with high crystallization performance can be obtained. 2 Ti 2 o 7 : Er nanomaterials.

[0050] figure 1 gives the obtained Er 2 Ti 2 o 7 The scanning electron micrograph (S...

Embodiment 2

[0052] DMF and acetic acid were mixed in a mass ratio of 0.4:1, and a transparent solution was formed by magnetic stirring; then 0.81ml of tetrabutyl titanate was added and fully dissolved by stirring; 0.13g of erbium nitrate was added under rapid stirring; After it was fully dissolved, 1.02 g of bismuth nitrate was added and fully stirred to dissolve it, and finally PVP with a mass fraction of 6% was added, and the electrospinning precursor was obtained after magnetic stirring. Under the conditions of control voltage of 20KV and flow rate of 12μl / m, a large amount of nanomaterials appeared on the collector. After the electrospinning was completed, the nanomaterials on the collector were transferred to the muffle furnace and heated at 6°C / min. Increase the rate to 650°C for 1.5 hours to obtain pyrochlore phase Bi with high crystallinity 2 Ti 2 o 7 : Er nanomaterials.

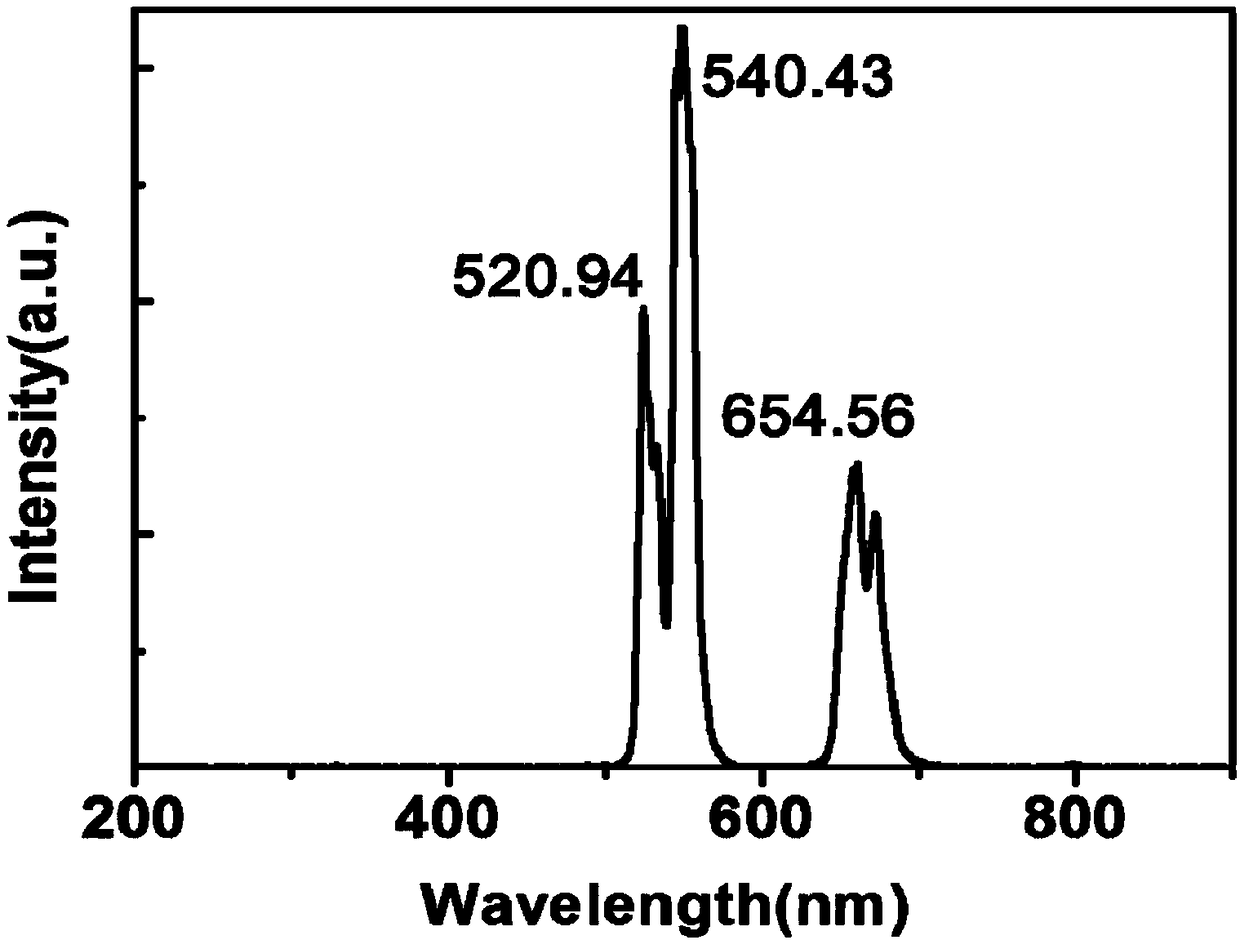

[0053] figure 2 Given the laser with a wavelength of 980nm as the excitation source, the obtained up-con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com