A high color rendering index white light organic electroluminescent device and its preparation method

An electroluminescent device, high color rendering technology, applied in the direction of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of rare reports, low luminous efficiency of excimer associations, and white OLEDs that have not attracted scholars. concerns and other issues, to achieve the effect of simple structure, low production cost and wide range of choices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of the above-mentioned white light organic electroluminescence device, it comprises the following steps:

[0027] ①Use de-detergent, deionized water, acetone and ethanol solutions to ultrasonically clean the substrate in sequence, and put it in an oven for drying after cleaning.

[0028] ② Move the substrate into the vacuum coating chamber, prepare the anode layer, the hole transport layer, the blue light-emitting layer, the electron transport layer and the cathode layer by dry method or wet method in the order from bottom to top, and obtain White light organic electroluminescent devices. The anode layer, the hole transport layer, the blue light-emitting layer, the electron transport layer and the cathode layer are directly prepared sequentially by a dry method, or are sequentially prepared on the substrate through a wet process after being diluted with an organic solvent. For example, the process can be: vacuum evaporation Plating, ion beam depo...

Embodiment 1

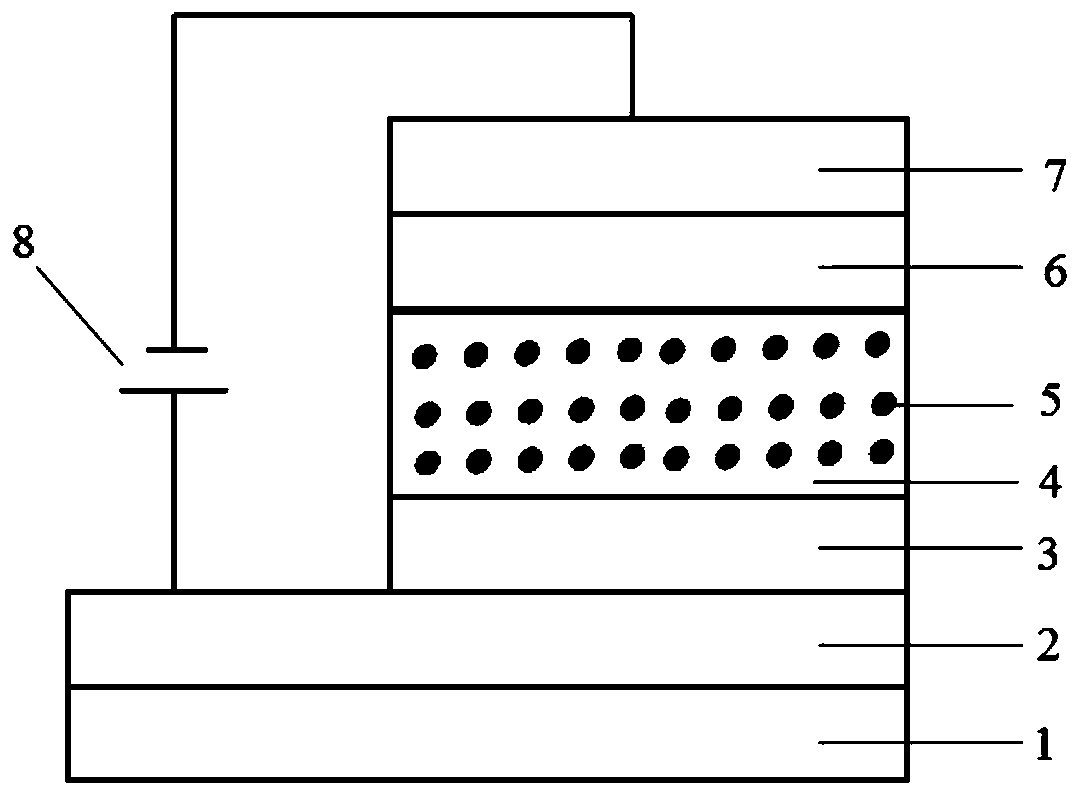

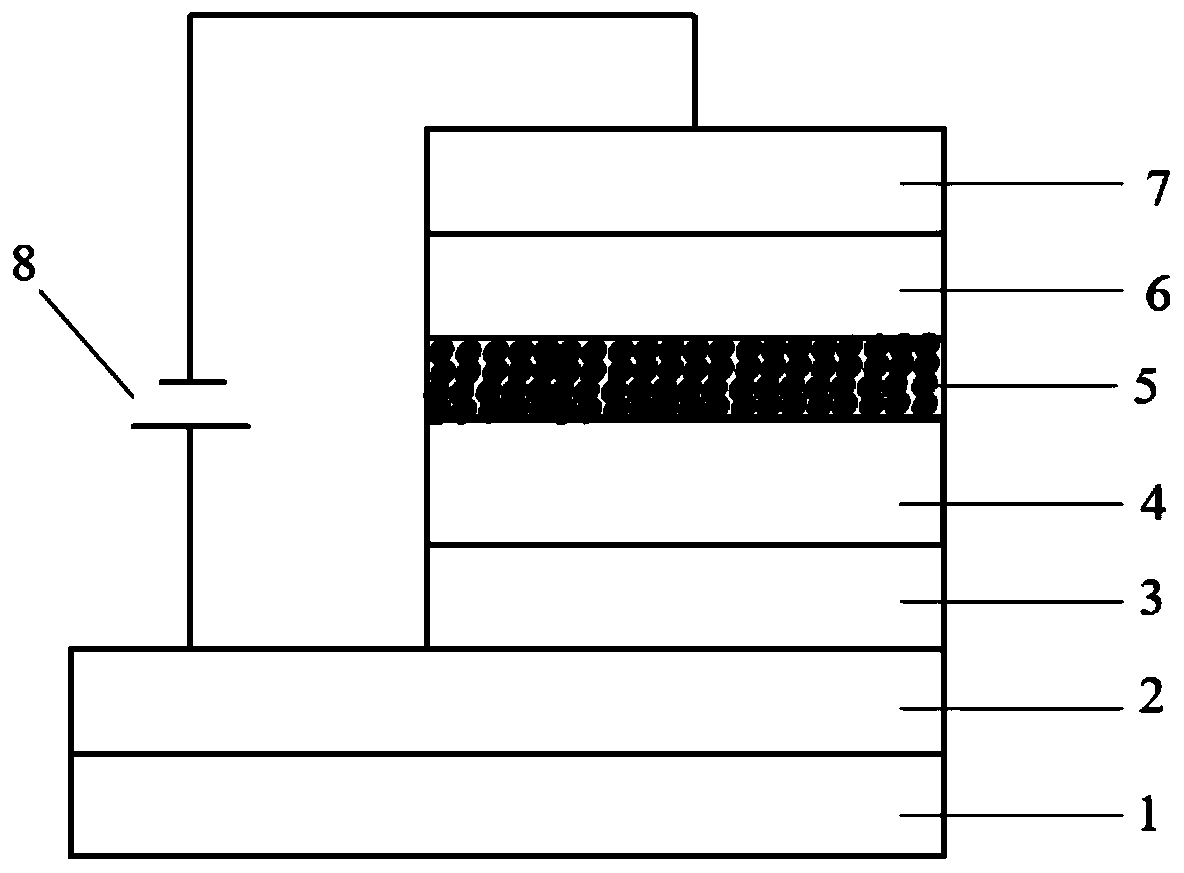

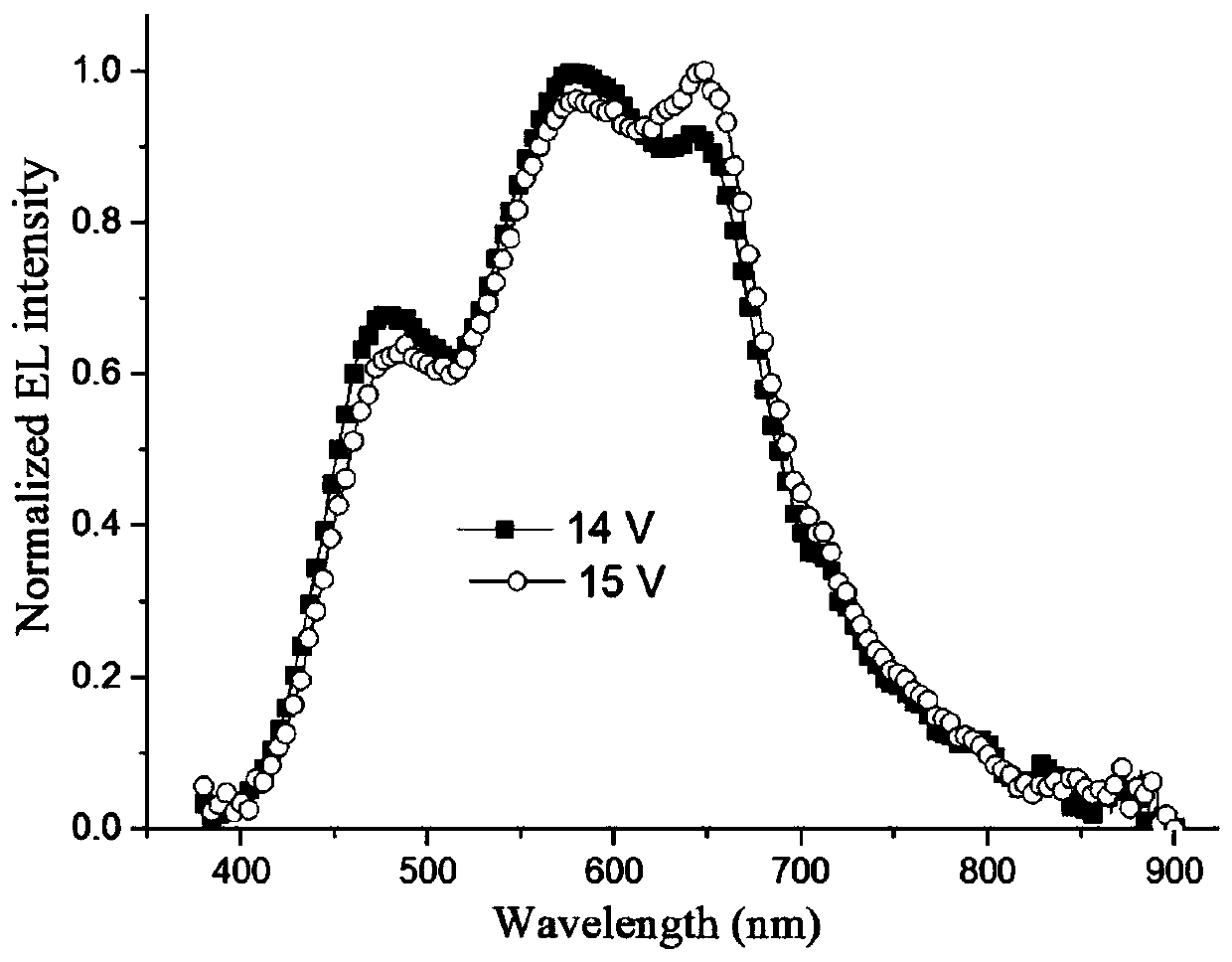

[0036] Such as figure 1 As shown, the hole transport layer 3 in the device structure is TAPC, the host material 4 in the blue light-emitting layer is MCP, and the blue fluorescent light-emitting material 5 is a blue fluorescent light-emitting material DMACDPS (wherein the electron donor The group is acridine series 9,9-dimethyl-9,10-dihydroacridine (DMAC), the electron acceptor group is diphenylsulfone series Diphenylsulphone (DPS)), and the doping mass ratio is guest material: host material = 10% , the material used for the electron transport layer 6 is TPBi, and the cathode layer is Mg:Ag alloy with a ratio of 10:1. The entire device structure is described as:

[0037] Glass substrate / ITO / TAPC(40nm) / MCP:10%DMACDPS(20nm) / TPBi(40nm) / Mg:Ag(10:1, 200nm)

[0038] The preparation method is as follows:

[0039] (1) Use detergent, deionized water, acetone and ethanol solutions to ultrasonically clean the transparent conductive substrate ITO glass, and put it in an oven for drying...

Embodiment 2

[0046] Such as figure 1 As shown, the hole transport layer 3 in the device structure is TAPC, the host material 4 in the blue light-emitting layer is MCP, and the blue fluorescent light-emitting material 5 is a blue fluorescent light-emitting material DMACDPS (wherein the electron donor The group is acridine series 9,9-dimethyl-9,10-dihydroacridine (DMAC), the electron acceptor group is diphenyl sulfone series Diphenylsulphone (DPS)), and the doping mass ratio is guest material: host material = 20% , the material used for the electron transport layer 6 is TPBi, and the cathode layer is Mg:Ag alloy with a ratio of 10:1. The entire device structure is described as:

[0047] Glass substrate / ITO / TAPC(60nm) / MCP:20%DMACDPS(20nm) / TPBi(40nm) / Mg:Ag(10:1, 200nm)

[0048] The preparation steps of the device are similar to those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com