Frost-resistant and crack-proof concrete and preparation method and application thereof

A concrete and anti-cracking technology, applied in dams, barrages, weirs, etc., can solve the problems of easy cracking of panels, easy segregation of fresh concrete, poor impermeability, etc., to speed up the progress, save repeated tests and Adjustment, the effect of strong crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

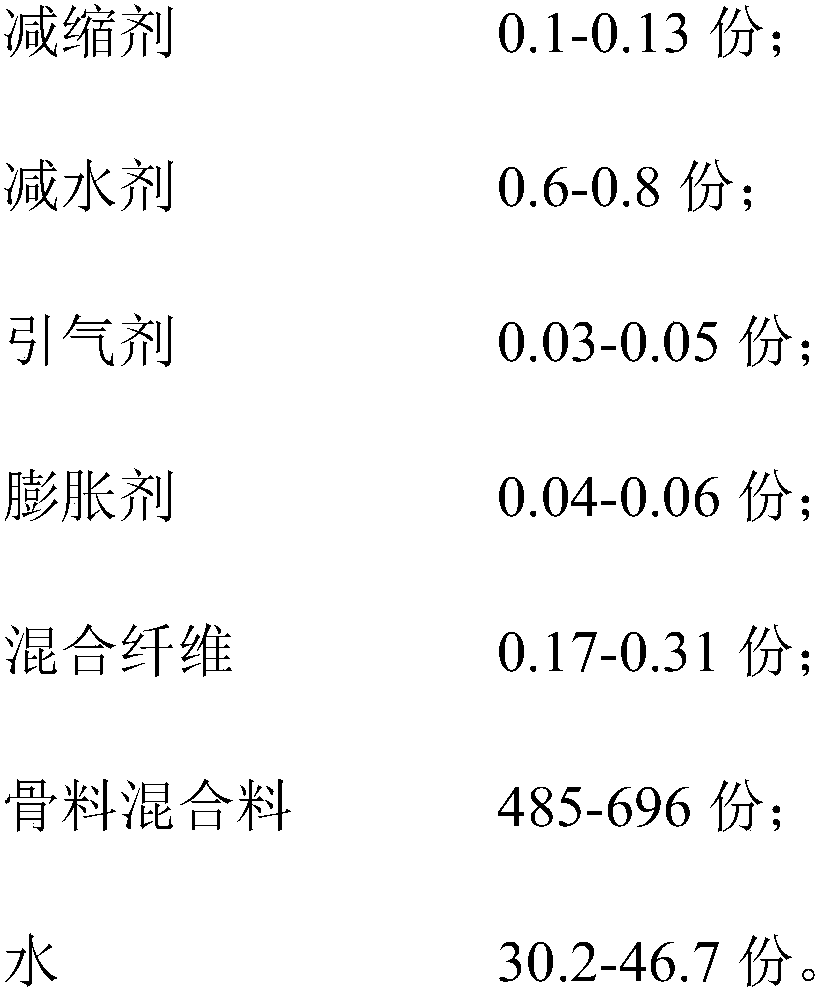

[0053] The present embodiment provides a kind of preparation method of frost-resistant and anti-crack concrete, specifically comprises the following steps:

[0054] Polyvinyl alcohol, glycerol, tetraethyl orthosilicate and calcium formate are fully mixed at a mass ratio of 52:11:21:10 to obtain a shrinkage reducing agent; polycarboxylate ether, sodium naphthalene xanthate formaldehyde polymer and sulfamic acid The sodium is fully mixed according to the mass ratio of solid content of 82:9:4 to obtain a water reducer; the polycarboxylate ethyl ether and sodium rosinate are fully mixed according to the mass ratio of solid content of 78:14, and the mixed liquid is added to the mixed liquid. % polyvinyl alcohol cross-linked polymer to obtain an air-entraining agent; magnesium oxide, aluminum powder and sodium aluminate are fully mixed at a mass ratio of 89:1.2:6.5 to obtain an expansion agent. Continuously graded artificial crushed stones with a nominal particle size of 20-40mm and...

Embodiment 2

[0060] The present embodiment provides a kind of preparation method of frost-resistant and anti-crack concrete, specifically as follows:

[0061] Polyvinyl alcohol, glycerol, tetraethyl orthosilicate and calcium formate are fully mixed in a mass ratio of 58:14:23:11 to obtain a shrinkage reducing agent; polycarboxylate, sodium naphthalene xanthate formaldehyde polymer and sulfamic acid Formaldehyde polymer is fully mixed according to the mass ratio of solid content of 87:11:7 to obtain a water reducer; polycarboxylate sodium sulfate and rosin formaldehyde are fully mixed according to the mass ratio of solid content of 86:22, and the mixed liquid is added to the mixed liquid 4% by mass of polyvinyl alcohol cross-linked polymer to obtain an air-entraining agent; magnesium oxide, aluminum powder and sodium aluminate are fully mixed at a mass ratio of 92:1.5:9.8 to obtain an expansion agent. Continuously graded artificial crushed stones with a nominal particle size of 20-40mm and ...

Embodiment 3

[0067] The present embodiment provides a kind of preparation method of frost-resistant and anti-crack concrete, specifically as follows:

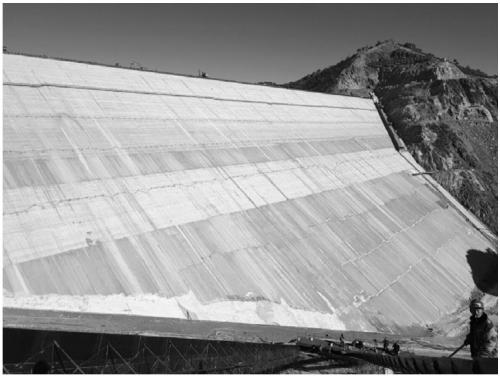

[0068] The maximum dam height of a rockfill face dam in North China is 120.3m, the maximum slant length of the reinforced concrete face is nearly 203m, and the concrete pouring volume is 34,000m 3 , with a total area of 66,900 m 2 . The concrete face rockfill dam is located in a cold region, and the lowest recorded temperature in winter can reach -40°C. The face plate of the face rockfill dam is required to be frost-resistant.

[0069] Polyvinyl alcohol, glycerol, tetraethyl orthosilicate and calcium formate are fully mixed at a mass ratio of 52:14:23:11 to obtain a shrinkage reducing agent; polycarboxylated acrylic acid, sodium naphthalene xanthate formaldehyde polymer and sulfamic acid The lignin graft copolymer is fully mixed according to the mass ratio of solid content of 82:11:7 to obtain a water reducing agent; the polycarboxylate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nominal particle size | aaaaa | aaaaa |

| Nominal particle size | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com