Bio-based epoxy resin based on natural amino acids, and preparation method and application thereof

A technology of natural amino acid and epoxy resin, applied in the direction of organic chemistry, etc., to achieve the effect of saving petroleum resources, good controllability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Dissolve 1 mol of alanine, 1.2 mol of vanillin, and 1 mol of KOH in 250 mL of ethanol, react at 30°C for 24 hours, add 3 mol of sodium borohydride and control the reaction temperature at 10°C, at this temperature The reaction was continued for 36 hours to finally obtain the alanine-vanillin multifunctional monomer with a yield of 89%.

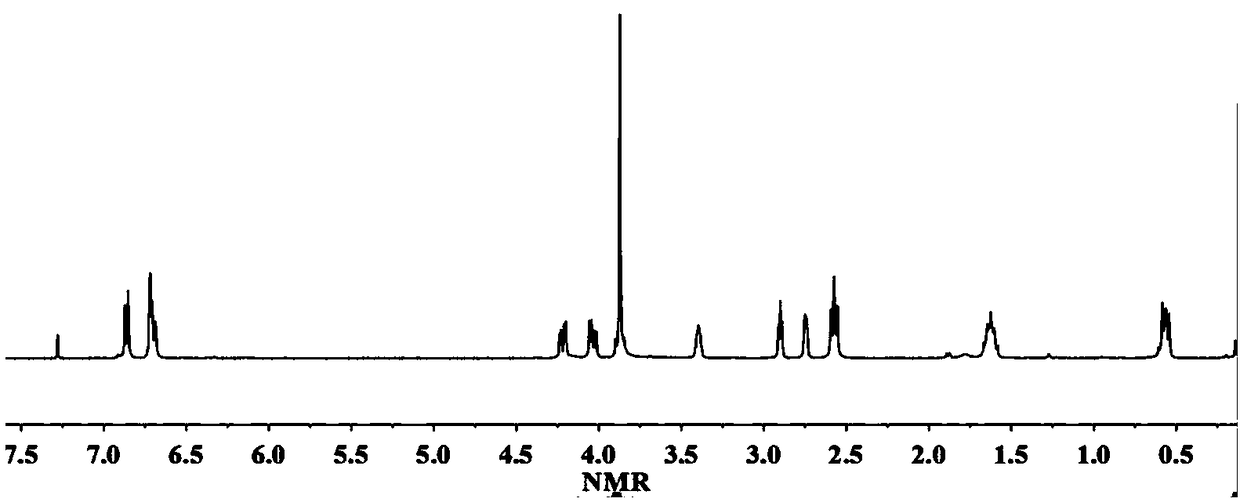

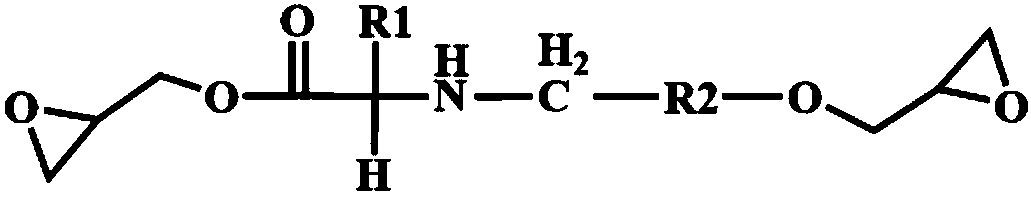

[0039] React 1 mol of alanine-vanillin multifunctional monomer and 5 mol of epichlorohydrin in the presence of 0.1 mol of tetrabutylammonium bromide at 100°C for 2 hours, then remove the solvent by rotary evaporation under reduced pressure, wash with water And after drying, the epoxidized alanine-vanillin compound was obtained with a yield of 93%. H NMR spectrum 1 H-NMR such as figure 1 As shown, each peak on the figure is in one-to-one correspondence with the hydrogen atoms on the epoxidized alanine-vanillin dicyanide compound structure.

[0040]Mix the obtained epoxidized alanine-vanillin compound and curing agent DDS in acetone acc...

Embodiment 2

[0042] Dissolve 1 mol of lysine, 2.5 mol of vanillin, and 1.1 mol of KOH in 200 mL of ethanol, react at 50°C for 16 hours, add 4 mol of sodium borohydride and control the reaction temperature at 20°C, at this temperature The reaction was continued for 24 hours to finally obtain a lysine-vanillin multifunctional monomer with a yield of 81%.

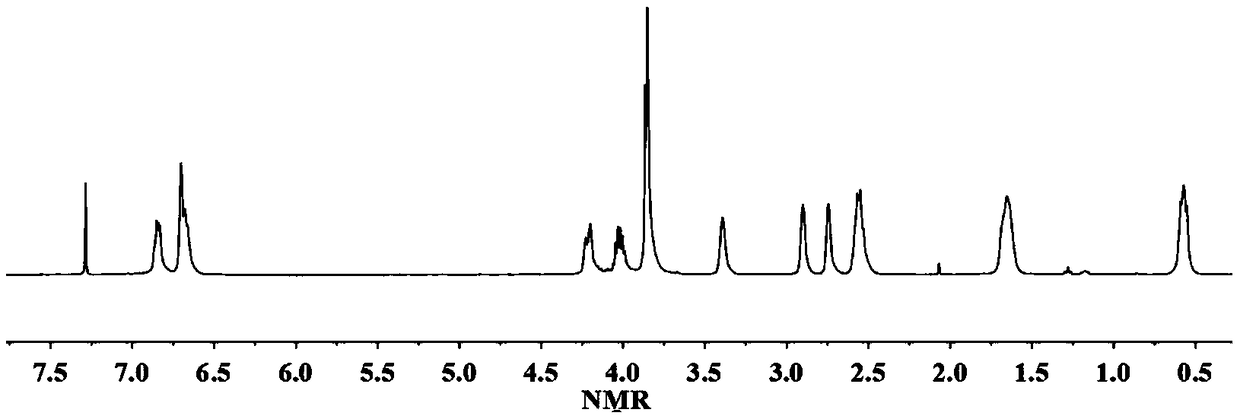

[0043] React 1mol lysine-vanillin multifunctional monomer and 8mol epichlorohydrin in the presence of 0.15mol tetrabutylammonium bromide at 80°C for 5 hours, then remove the solvent by rotary evaporation under reduced pressure, wash with water And after drying, the epoxidized lysine-vanillin compound was obtained with a yield of 91%. H NMR spectrum 1 H-NMR such as figure 2 As shown, each peak on the figure is in one-to-one correspondence with the hydrogen atoms on the epoxidized lysine-vanillin dicyanide compound structure.

[0044] Mix the obtained epoxidized lysine-vanillin compound and the curing agent DDS in acetone according to th...

Embodiment 3

[0046] Dissolve 1 mol of tyrosine, 1.5 mol of vanillin, and 1.5 mol of KOH in 180 mL of ethanol, react at 80°C for 12 hours, add 2 mol of sodium borohydride and control the reaction temperature at 30°C, at this temperature The reaction was continued for 12 hours to finally obtain a tyrosine-vanillin multifunctional monomer with a yield of 79%.

[0047] React 1mol tyrosine-vanillin multifunctional monomer and 12mol epichlorohydrin in the presence of 0.2mol tetrabutylammonium bromide at 70°C for 8 hours, then remove the solvent by rotary evaporation under reduced pressure, wash with water And after drying, the epoxidized tyrosine-vanillin compound was obtained with a yield of 87%.

[0048] Mix the obtained epoxidized tyrosine-vanillin compound and the curing agent DDS in acetone according to the molar ratio of epoxy and NH one to one, then heat and pre-cure in a blast oven, and finally carry out at 180°C After curing for 2 hours, a cured product of tyrosine-vanillin-DDS epoxy r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com