Method for preparing DMF (2,5-dimethylfuran) from HMF (5-hydroxymethylfurfural) by catalytic hydrogenation

A technology of hydroxymethylfurfural and dimethylfuran, which is applied in the field of catalytic hydrogenation of 5-hydroxymethylfurfural to prepare 2,5-dimethylfuran, can solve the problems of low selectivity, poor stability, and high price. Achieve the effect of simple preparation method and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

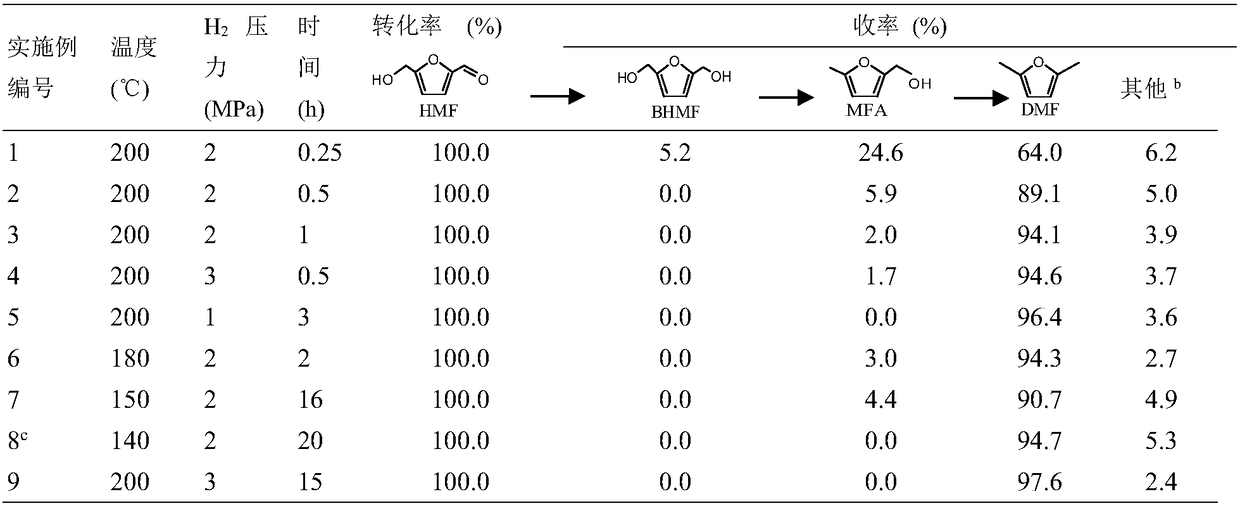

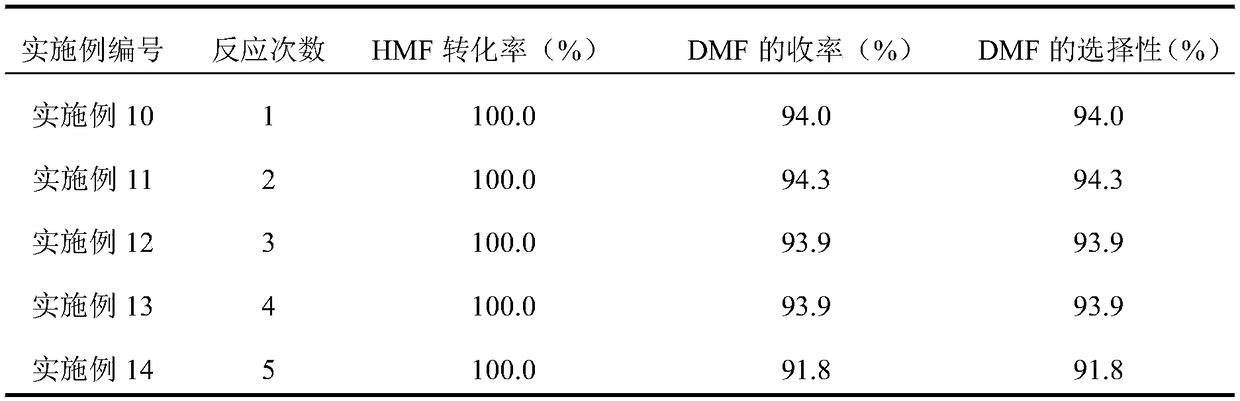

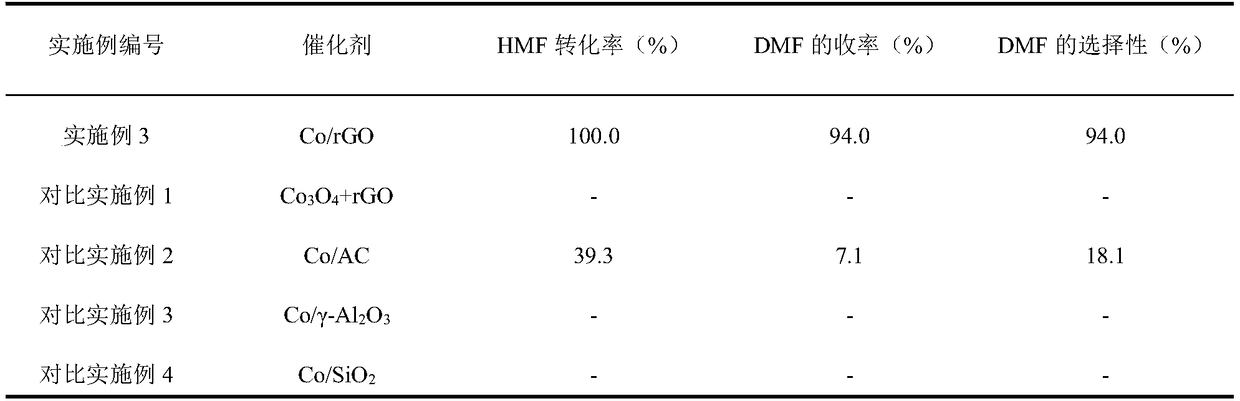

[0021] Co / rGO catalyzes the batch reaction of HMF to prepare DMF under different reaction conditions in Example 1-9

[0022] 1. Catalyst preparation: Co / rGO catalyst was prepared by co-precipitation method, the specific steps are:

[0023] (1) Preparation of salt solution: take Co(NO 3 ) 2 ·6H 2 O 0.3mmol was dissolved in deionized water to make 2.1mL salt solution;

[0024] (2) Preparation of carrier and test of water absorption: Graphene oxide (GO) was obtained according to Hummers method (Hummers WS, Offeman R E.Preparation of Graphitic Oxide.J Am Chem Soc 80:1339[J].Journalofthe American Chemical Society ,1958,80(6).) Prepared from graphite powder. Reduced graphene oxide (rGO) is produced by the reduction of GO. Disperse 1 g of GO in 1000 mL of deionized water, sonicate for 30 min, then transfer to a round-bottomed flask, add 25 mL of 30% ammonia water and 6 mL of 80% hydrazine hydrate, reflux at 95 °C for 3 h under magnetic stirring at 2000 rpm, then add 4 mL of 80% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com