Cross-linked block polymer anion exchange membrane, preparation method and applications thereof

An anion exchange membrane and block polymer technology, which is applied in the field of preparation of cross-linked block polymer anion exchange membranes, can solve the problem that low-level secondary amines cannot be highly cross-linked in the polymer skeleton, and there is little room for improvement in membrane stability. , The polymer substrate contains ether bonds and other problems, and achieves the effects of excellent dimensional stability and chemical stability, low cost and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

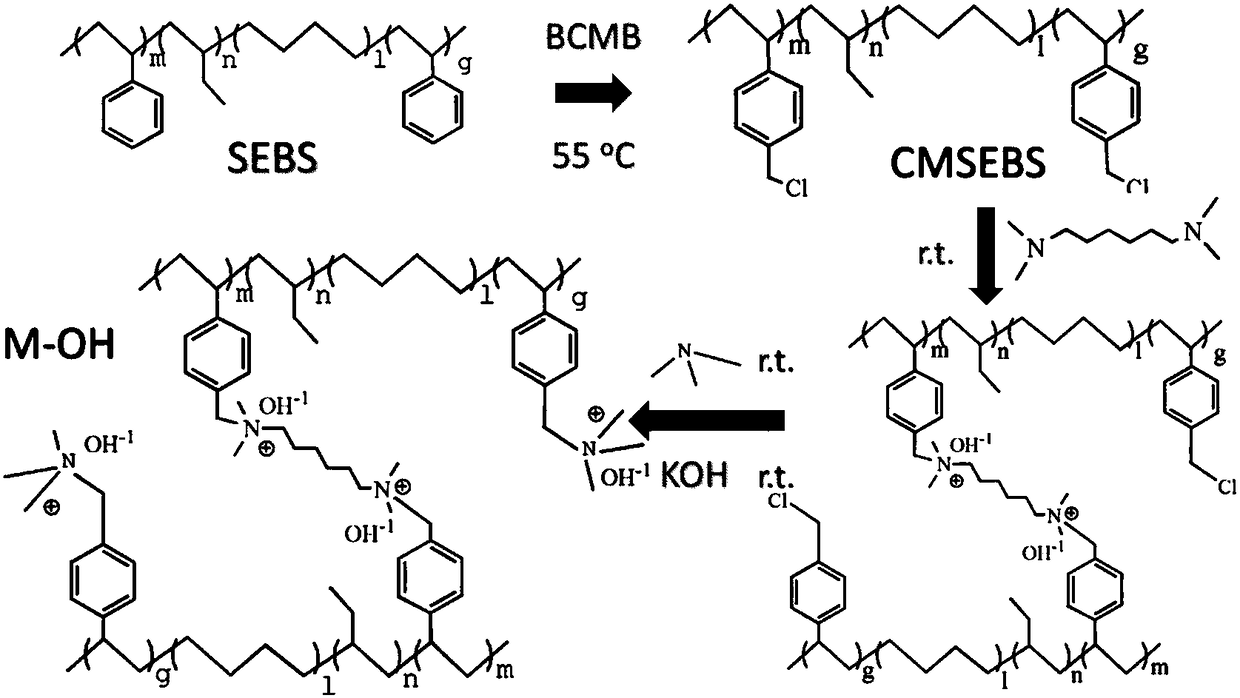

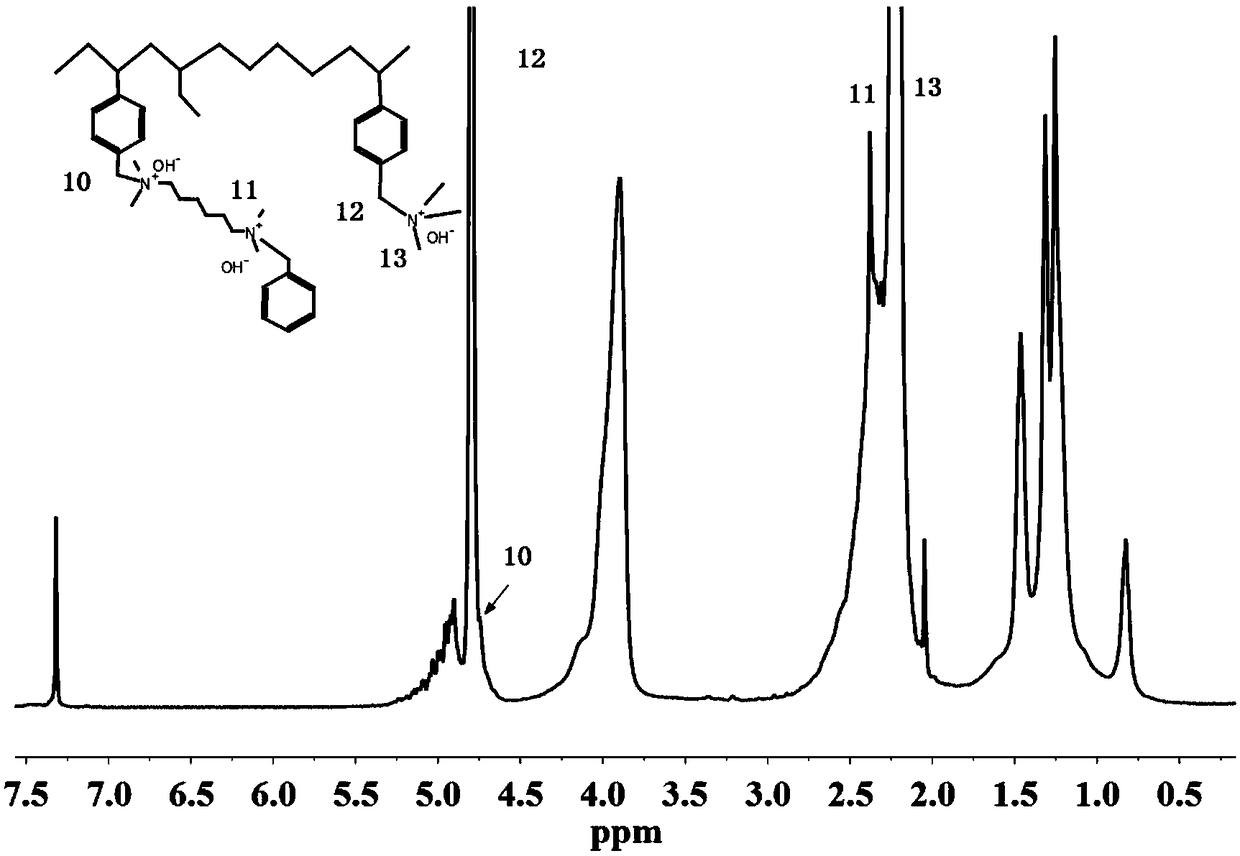

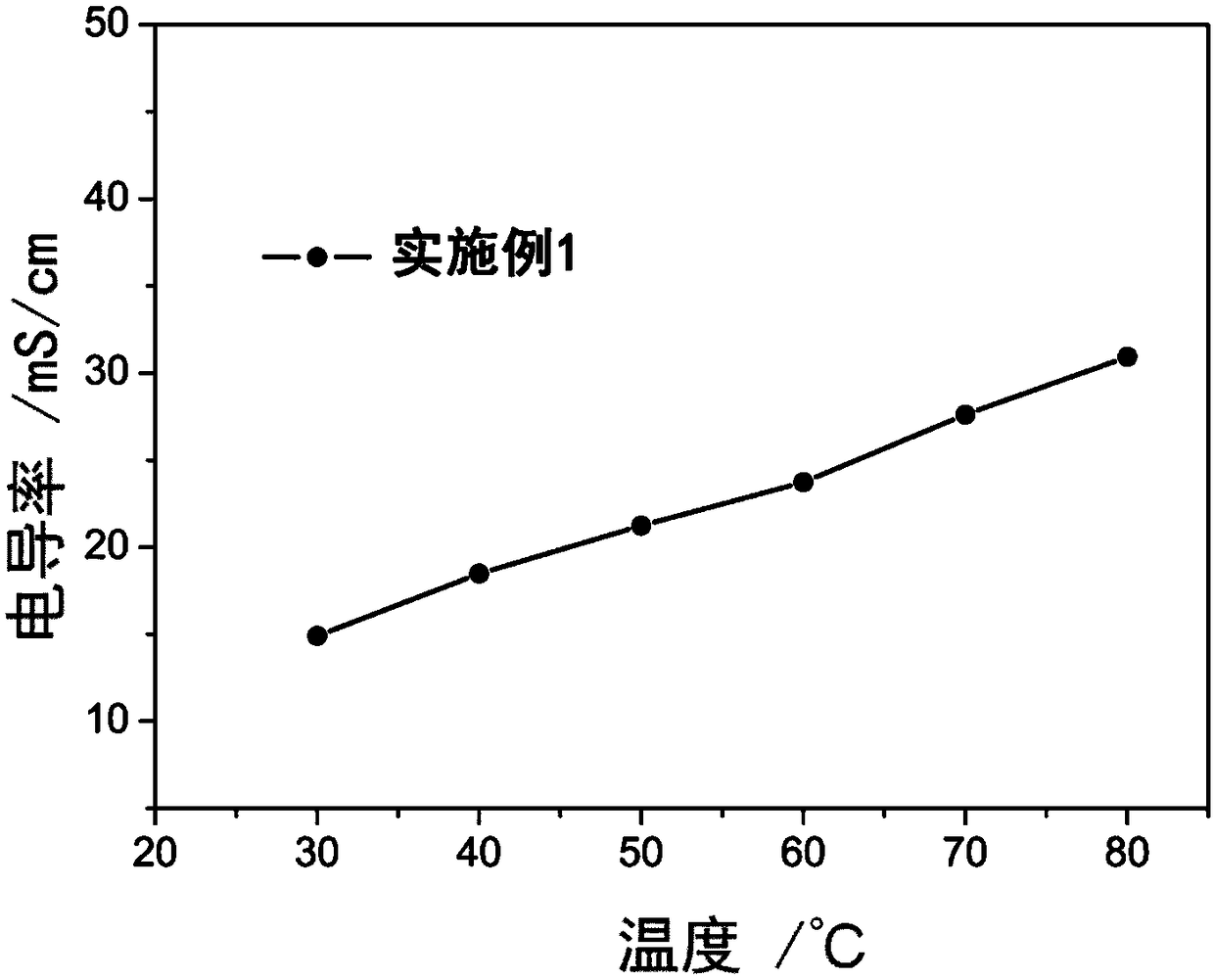

[0033] Dissolve 5g of polystyrene-ethylene-butylene-styrene (SEBS) with molecular weight Mn≈130000 and 58wt.% styrene block content in 150mL of organic reagent chloroform, stir at 55°C for 5 hours, add 7mL of SnCl 4 and 46mL BCMB, reacted for 3h, poured the reacted solution into anhydrous methanol, precipitated the polymer, filtered it with suction, washed it with deionized water until neutral, and dried it in a vacuum oven at 60°C to obtain chloromethyl Polystyrene-ethylene-butylene-styrene (CMSEBS). Then it was dissolved in chloroform solution to form a 5wt.% solution, and N,N,N',N'-tetramethyl-1,6-hexamethylenediamine (TMHDA) was added to it, the number of moles of which was CMSEBS 1 times, stir at room temperature for 60 seconds, then pour into a glass box, put it in an oven at 60°C, heat for 24 hours, dry the solvent, and remove it.

[0034] Soak the membrane in trimethylamine aqueous solution at room temperature, take it out after soaking for 24 hours, and obtain the cr...

Embodiment 2

[0040] Dissolve 10 g of polystyrene-ethylene-butylene-styrene (SEBS) with a molecular weight of Mn≈130000 and a styrene block content of 42 wt.% in 150 mL of organic reagent chloroform, stir at 55 °C for 6 hours, and add 13 mL of SnCl 4 React with 88mL BCMB for 10h. Pour the reacted solution into anhydrous methanol. After the polymer is precipitated, filter it with suction, wash it with deionized water until neutral, and then dry it in a vacuum oven at 60°C to obtain chloromethyl Polystyrene-ethylene-butylene-styrene (CMSEBS). Then it was dissolved in chloroform solution to form a 3wt.% solution, and N,N,N',N'-tetramethyl-1,6-hexamethylenediamine (TMHDA) was added to it, the number of moles of which was CMSEBS 1.5 times, stirred at room temperature for 30 seconds, then poured into a glass frame, placed in an oven at 60°C, heated for 24 hours, dried the solvent, and removed.

[0041] Soak the membrane in trimethylamine aqueous solution at room temperature, take it out after so...

Embodiment 3

[0046] Dissolve 10g of polystyrene-ethylene-butylene-styrene (SEBS) with molecular weight Mn≈80000 and 3.7wt.% styrene block content in 300mL of organic reagent chloroform, stir at 60°C for 5 hours, add 15mL of SnCl 4 and 95mL BCMB, reacted for 10h, poured the reacted solution into anhydrous methanol, precipitated the polymer, filtered it with suction, washed it with deionized water until neutral, and dried it in a vacuum oven at 60°C to obtain chloromethyl Polystyrene-ethylene-butylene-styrene (CMSEBS). Then it was dissolved in chloroform solution to form a 5wt.% solution, and N,N,N',N'-tetramethyl-1,6-hexamethylenediamine (TMHDA) was added to it, the number of moles of which was CMSEBS 0.5 times, stirred at room temperature for 60 seconds, then poured into a glass frame, placed in an oven at 60°C, heated for 24 hours, dried the solvent, and removed.

[0047] Soak the membrane in trimethylamine aqueous solution at room temperature, take it out after soaking for 24 hours, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com