Preparation method of composite bacterial agent for sludge composting and application thereof

A compound bacterial agent and composting technology, applied in the field of microbial fermentation, can solve the problems of unsatisfactory fertilizer effect, single microbial effect, and difficulty in wide application, and achieve the effects of improving crop stress resistance, shortening composting time, and promoting growth and reproduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

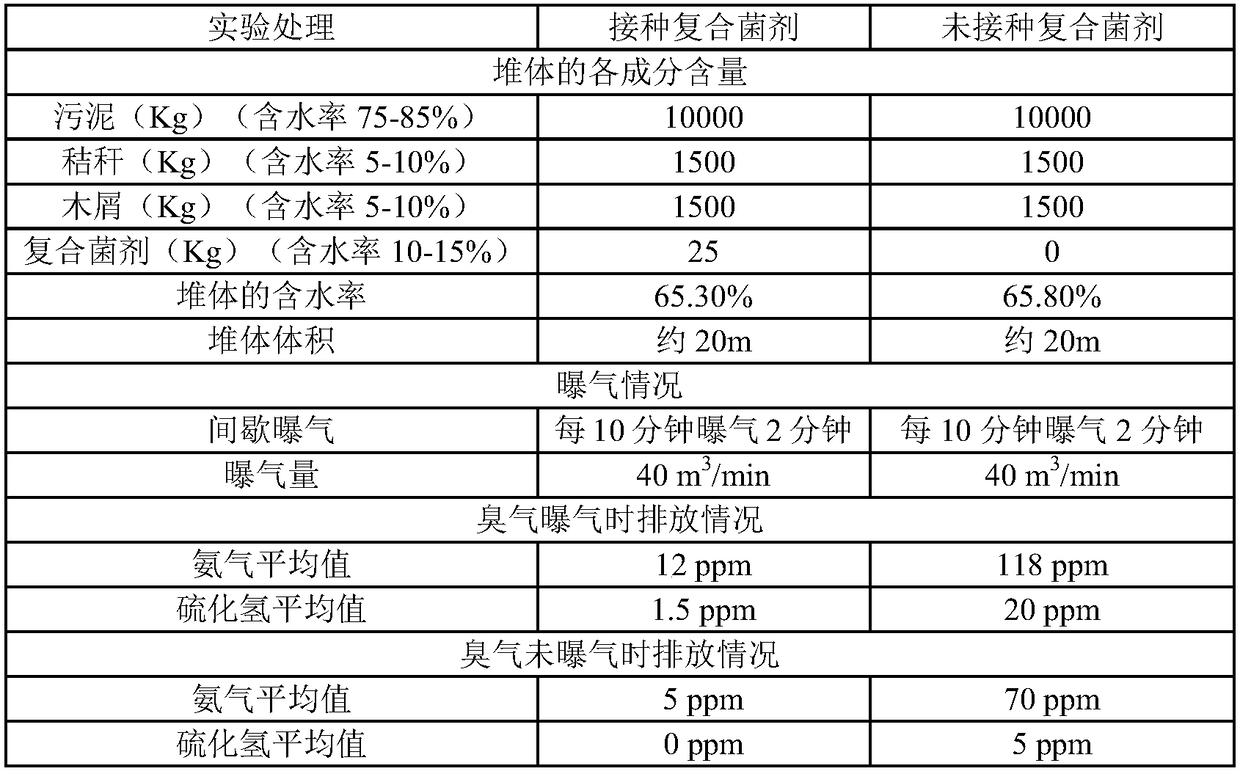

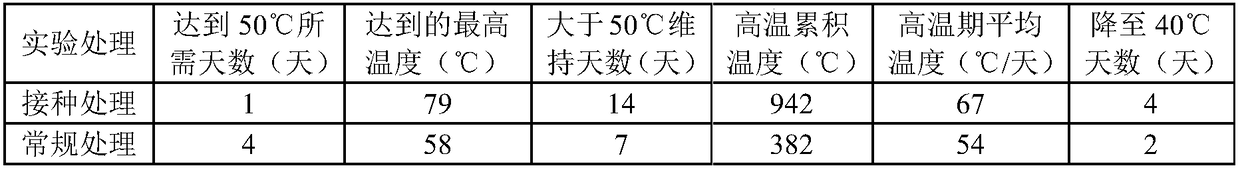

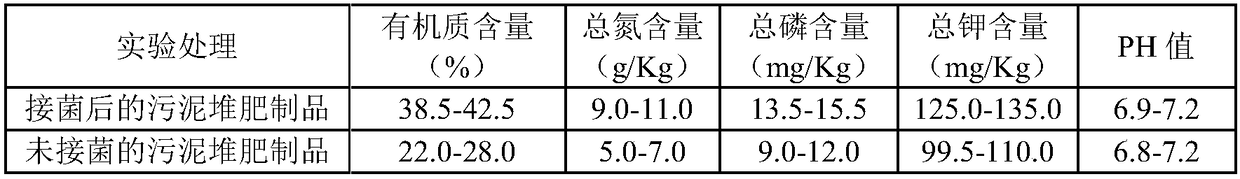

Examples

preparation example Construction

[0023] The preparation method of each bacterial strain in the described composite bacterial agent is as follows:

[0024] (1) The preparation of the Bacillus uplander bacteria liquid is as follows: pick the Bacillus uplander strains and inoculate them into a solid slant culture, place them in the medium for cultivation, the culture temperature is 37° C., and the culture time is 24 hours, and wait for the slant culture After the colonies grow out of the base, inoculate them into the liquid medium for shaker culture. The shaker speed is 150-180r / min, the culture temperature is 35-37°C, and the culture time is 36-48h. When the number of viable bacteria reaches 1×10 8 When CFU / mL, the preparation of the bacterial solution is completed; the solid slant medium is made by mixing the following raw materials in the weight ratio: glucose 5g, peptone 5g, beef extract 3g, NaCl 5g, agar 15g, supplemented with distilled water to 1L, pH =7, sterilized at 121°C for 30 minutes and cooled for ...

Embodiment 1

[0031] After mixing the bacterial solutions of Bacillus highlander, Streptomyces violaceum, Geobacillus stearothermophilus, Bacillus subtilis and Bacillus licheniformis at a volume ratio of 0.5:0.5:0.2:0.5:0.2, the fermentation after high temperature sterilization Inoculate with a medium volume ratio of 8%, ferment at 35°C for 5 days, when the number of viable bacteria reaches 1×10 8 When the CFU / mL is above, the culture is complete. The fermentation medium is made by mixing the following raw materials in weight ratio: brown sugar 15-25g, peptone 5-10g, beef extract 3-5g, NaCl2-5g, KH 2 PO 4 0.75-1.5g, MgSO 4 .7H 2 O 0.5-1g, K 2 HPO 4 0.8-1g, vitamin B1 10-15mg, potato extract 1L (take 200g peeled potatoes, cut into small pieces, add 1L of water and boil for 30min, filter out the potato pieces, make up the filtrate to 1L), PH=7, extinguish at 121℃ Cool for 30 minutes before use.

Embodiment 2

[0033] After mixing the bacterial solutions of Bacillus highlander, Streptomyces violaceum, Geobacillus stearothermophilus, Bacillus subtilis and Bacillus licheniformis at a volume ratio of 0.8:0.8:0.5:0.8:0.5, the fermentation after high temperature sterilization Inoculate with a medium volume ratio of 10%, ferment at 35°C for 5 days, when the number of viable bacteria reaches 1×10 8 When the CFU / mL is above, the culture is complete. The fermentation medium is made by mixing the following raw materials in weight ratio: brown sugar 15-25g, peptone 5-10g, beef extract 3-5g, NaCl2-5g, KH 2 PO 4 0.75-1.5g, MgSO 4 .7H 2 O 0.5-1g, K 2 HPO 4 0.8-1g, vitamin B1 10-15mg, potato extract 1L (take 200g peeled potatoes, cut into small pieces, add 1L of water and boil for 30min, filter out the potato pieces, make up the filtrate to 1L), PH=7, extinguish at 121℃ Cool for 30 minutes before use.

[0034] This embodiment is the best embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com