Pollen silicon loading nanosilver modified separation membrane and preparation method thereof

A separation membrane and nano-silver technology, which is applied in semi-permeable membrane separation, chemical instruments and methods, membranes, etc., can solve the problem that the separation membrane cannot maintain high antibacterial efficiency for a long time, the release rate of silver ions is difficult to control, and the loading capacity of nano-silver is limited. and other problems, to achieve the effect of improving anti-pollution ability, easy industrial implementation, and high-efficiency and long-lasting antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

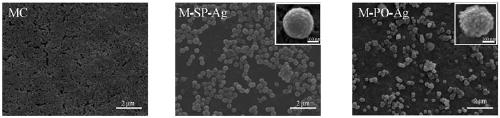

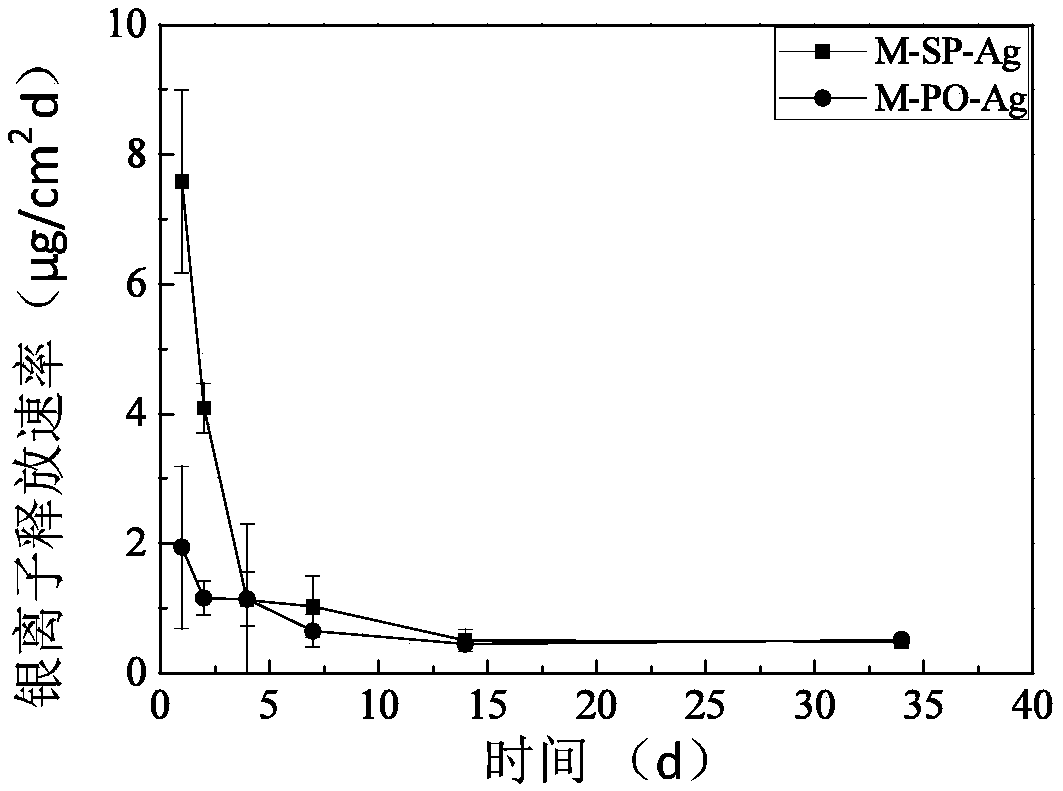

[0036] Preparation of pollen silicon-supported silver-modified polyvinylidene fluoride membrane:

[0037] (1) Dissolve 0.2wt.% resorcinol and 0.25wt.% formaldehyde in ethanol aqueous solution, stir under the catalysis of ammonia water for 6h to form spherical phenolic resin, wherein the mass fraction of ammonia water is 28% , the amount of ammonia water is 2wt.% of the ethanol aqueous solution; 0.8wt.% ethyl orthosilicate in the ethanol aqueous solution is added to the phenolic resin, and 0.5wt.% resorcinol and 0.62wt.% of the ethanol aqueous solution are added after 8 minutes. % formaldehyde, reacted for 2 hours, centrifuged, washed and dried, and burned at 550°C for 5 hours in the air atmosphere to obtain pollen silicon;

[0038] (2) dissolving pollen silicon in water (mass ratio of pollen silicon to water is 1:66) solution, under the catalysis of ammonia water, react with 0.75wt.% silver nitrate to pollen silicon aqueous solution for 24h, and the product is centrifuged, washe...

Embodiment 2

[0043] Preparation of pollen silicon-supported silver-modified polysulfone membrane:

[0044] (1) Dissolve 0.2wt.% resorcinol and 0.25wt.% formaldehyde in ethanol aqueous solution, stir under the catalysis of ammonia water for 6h to form spherical phenolic resin, wherein the mass fraction of ammonia water is 28% , the amount of ammonia water is 1wt.% of ethanol aqueous solution; 0.5wt.% methyl orthosilicate in ethanol aqueous solution is added to the phenolic resin, and 0.3wt.% resorcinol and 0.75wt.% ethanol aqueous solution are added again after 15min. % formaldehyde, reacted for 3 hours, centrifuged, washed and dried, and burned at 550°C for 5 hours in the air atmosphere to obtain pollen silicon;

[0045] (2) Dissolve pollen silicon in water (the mass ratio of pollen silicon to water is 1:55), react with 0.85wt.% silver nitrate to pollen silicon aqueous solution under the catalysis of ammonia water for 30h, and the product is centrifuged, washed and dried After drying, a s...

Embodiment 3

[0050] Preparation of pollen silicon-supported silver-modified polyvinylidene fluoride-polysulfone membrane:

[0051] (1) Dissolve 0.2wt.% resorcinol and 0.2wt.% formaldehyde in ethanol aqueous solution, stir under the catalysis of ammonia water for 6h to form spherical phenolic resin, wherein the mass fraction of ammonia water is 28% , the amount of ammonia water is 3wt.% of the ethanol aqueous solution; 0.5wt.% ethyl orthosilicate in the ethanol aqueous solution is added to the phenolic resin, and 0.7wt.% resorcinol and 0.55wt.% of the ethanol aqueous solution are added after 8 minutes. % formaldehyde, reacted for 2 hours, centrifuged, washed and dried, and burned at 550°C for 5 hours in the air atmosphere to obtain pollen silicon;

[0052] (2) Dissolve pollen silicon in water (the mass ratio of pollen silicon to water is 1:70), react with 0.68wt.% silver nitrate of pollen silicon aqueous solution under the catalysis of ammonia water for 18 hours, and the product is centrifu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com